High-low temperature test box capable of quickly changing temperature for double-temperature-zone thermal mechanical fatigue test

A high and low temperature test chamber, thermomechanical fatigue technology, applied in the direction of temperature control, laboratory equipment, non-electric variable control, etc., can solve the problems of only providing a single test temperature zone, slow temperature change rate, etc., to reduce heat loss, The effect of ensuring temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

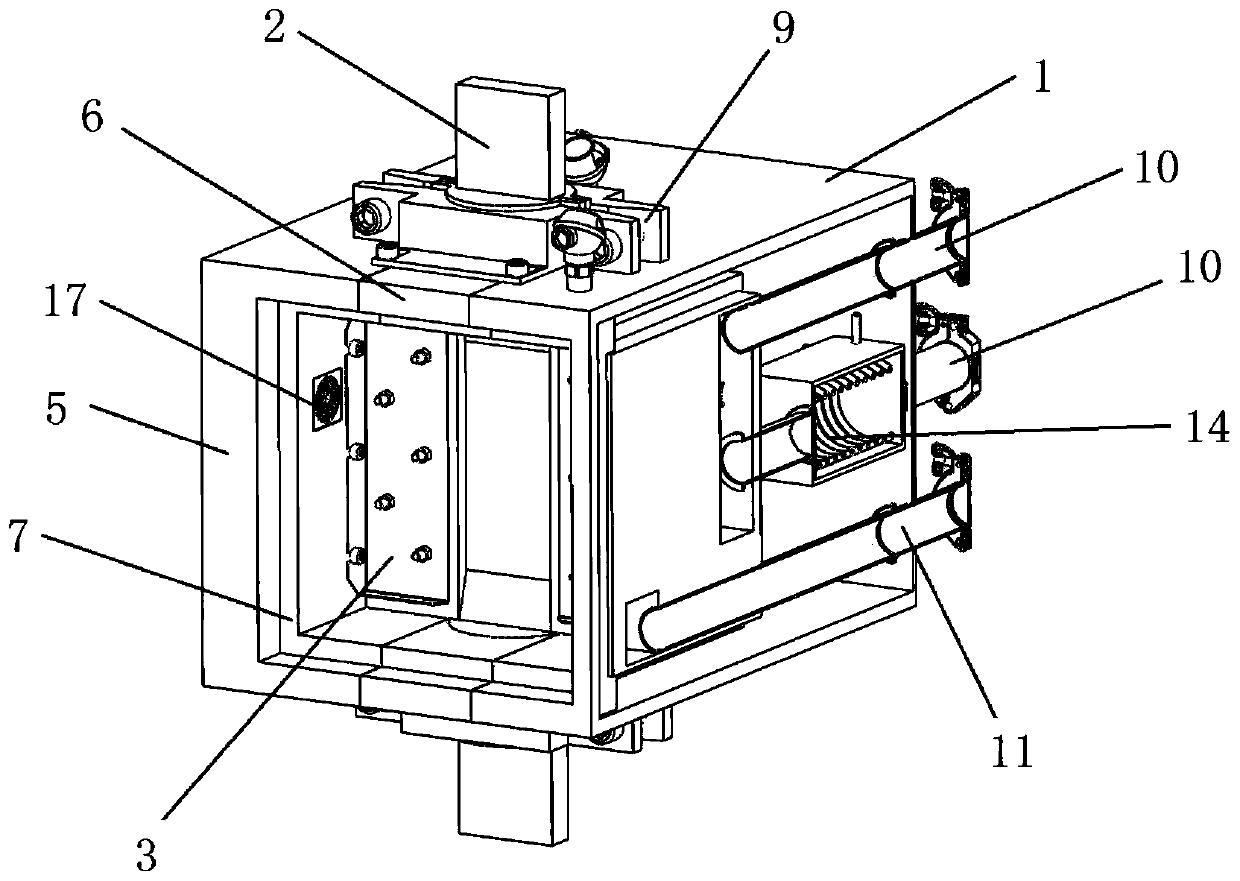

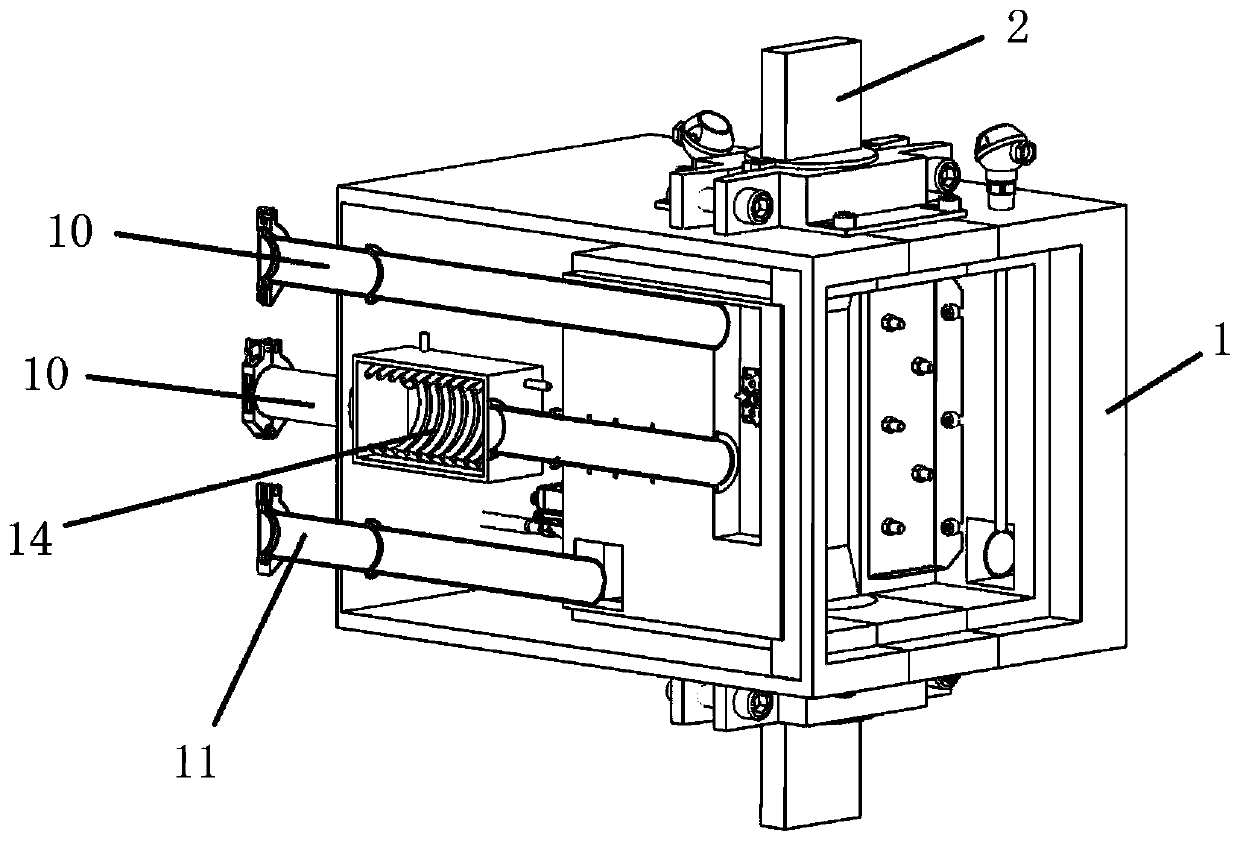

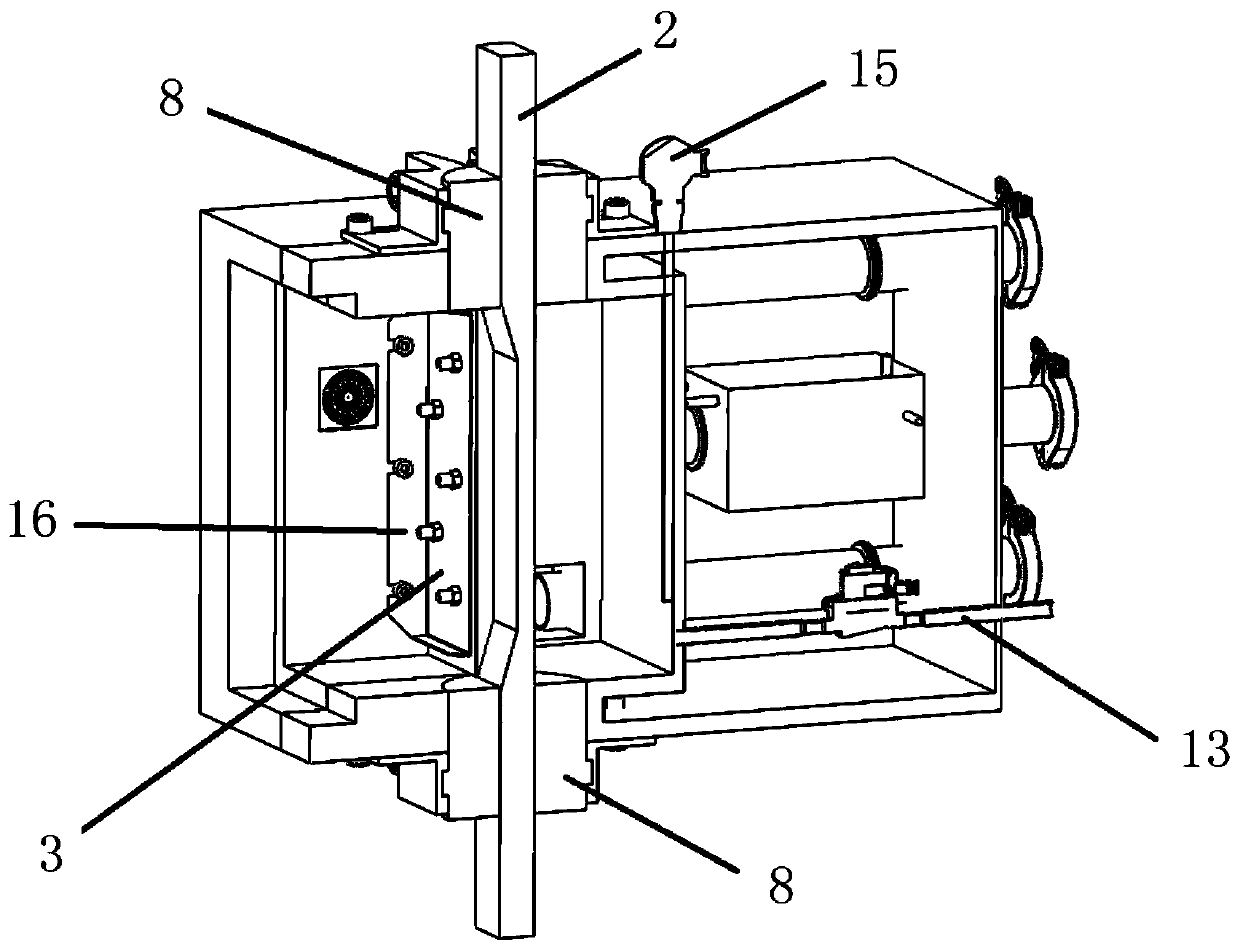

[0023] See attached Figure 1~4 As shown, this kind of high and low temperature test box for thermomechanical fatigue test with dual temperature zones that can change temperature quickly is used for thermomechanical fatigue test of transparent glass parts. The box body 1 is installed on the mechanical fatigue testing machine, and the fatigue sample 2 passes through The upper and lower end surfaces of the box body 1 are clamped between the upper and lower clamps of the mechanical fatigue testing machine, and a detachable mounting block 6 is arranged on the upper and lower end surfaces of the box door 5 side of the box body 1 to prevent fatigue. The sample 2 provides passages in and out of the box 1 . In the test box 7 in the box body 1, a partition plate 3 is arranged to divide the space in the test box 7 into two independent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com