A method for controlling the head width of hot-rolled finish-rolled steel strip to prevent stretching and narrowing

A technology of head width and control method, which is applied in the direction of rolling mill control device, tail end control, metal rolling, etc., can solve the problems of strip width narrowing, difficult to calculate accurately, and difficult to accurately predict the temperature of strip head, etc. To achieve the effect of avoiding strip narrowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

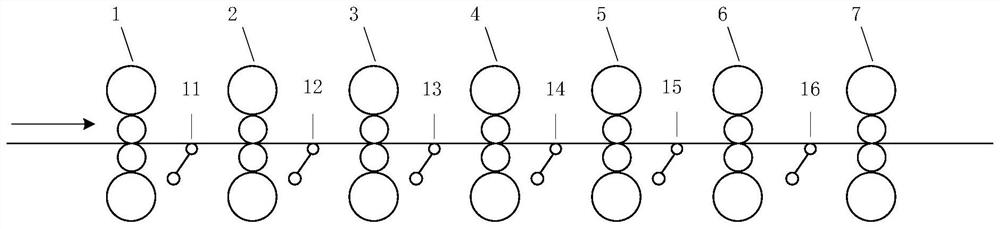

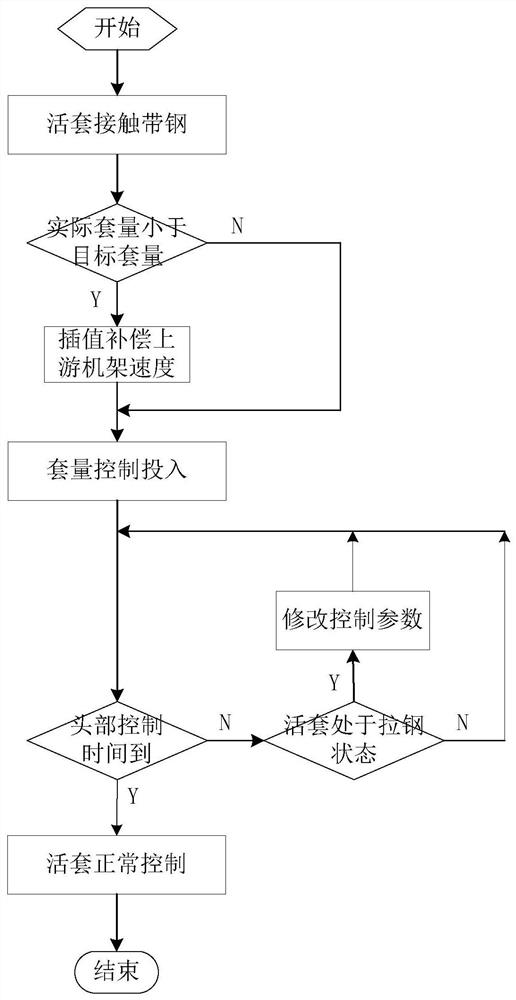

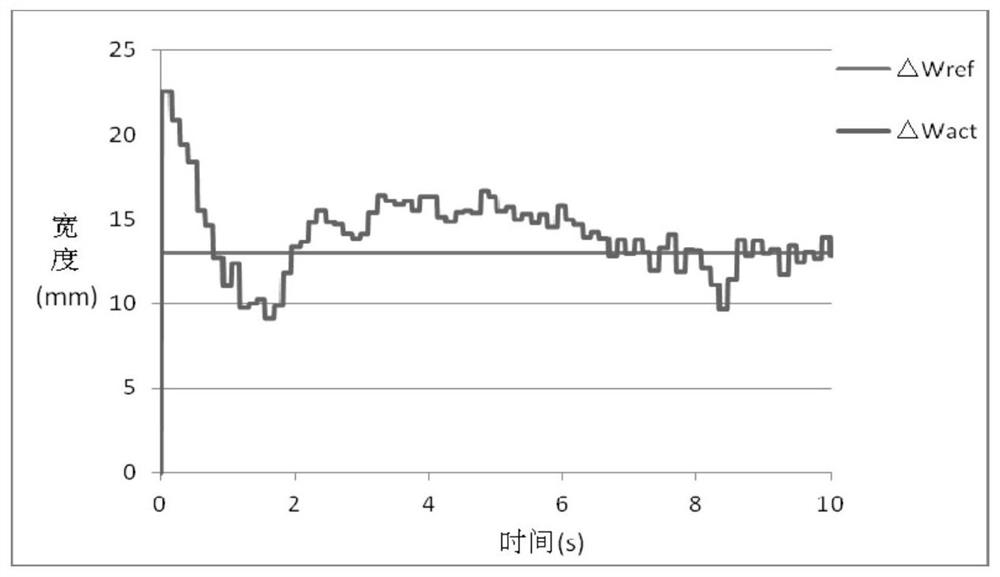

[0055] A method for controlling the width of the strip head in hot continuous rolling to prevent narrowing. For the 5# looper of a certain steel rolling, the control method for preventing the strip head from being narrowed is as follows:

[0056] S1. After the downstream frame bites the steel, the looper is lifted up quickly with a certain torque until it touches the strip steel. The condition for judging that the looper touches the strip steel is ω act max , and the value range of γ is 0.7. It can be obtained that the looper contacts the strip steel 500ms after F6 bites the steel.

[0057] S2. Record the set amount deviation L when the looper contacts the strip steel dev is 0.0016m, the upstream rack speed V touch is 7.71m / s, the maximum process speed V in the belt threading process of the upstream frame max is 9m / s, then according to the values in Table 1, calculate the upstream frame speed compensation value V add for:

[0058]

[0059] S3, take T s is 20s, ω Ju...

Embodiment 2

[0063] A method for controlling the head width of the hot-rolled finish-rolled steel strip to prevent narrowing. For the 3# looper of a certain steel rolling, the control method for preventing the strip head from being narrowed is as follows:

[0064] S1. After the downstream frame bites the steel, the looper is lifted up quickly with a certain torque until it touches the strip steel. The condition for judging that the looper touches the strip steel is ω act max , and the value range of γ is 0.7. It can be obtained that the looper touches the strip steel 600ms after F4 bites the steel.

[0065] S2. Record the set amount deviation L when the looper contacts the strip steel dev is 0.0028m, the upstream frame speed V touch is 3.08m / s, the maximum process speed V during the threading process of the upstream frame max is 5m / s, then according to the values in Table 2, calculate the upstream frame speed compensation value V add for:

[0066]

[0067] Table 2 V PLI Segmente...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap