Polishing device for stainless steel tee joint

A tee joint and polishing device technology, which is applied in the direction of grinding/polishing safety devices, surface polishing machine tools, grinding/polishing equipment, etc., can solve the problems of easy breakage and short life, so as to prolong the service life and prevent sparks Sputtering, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

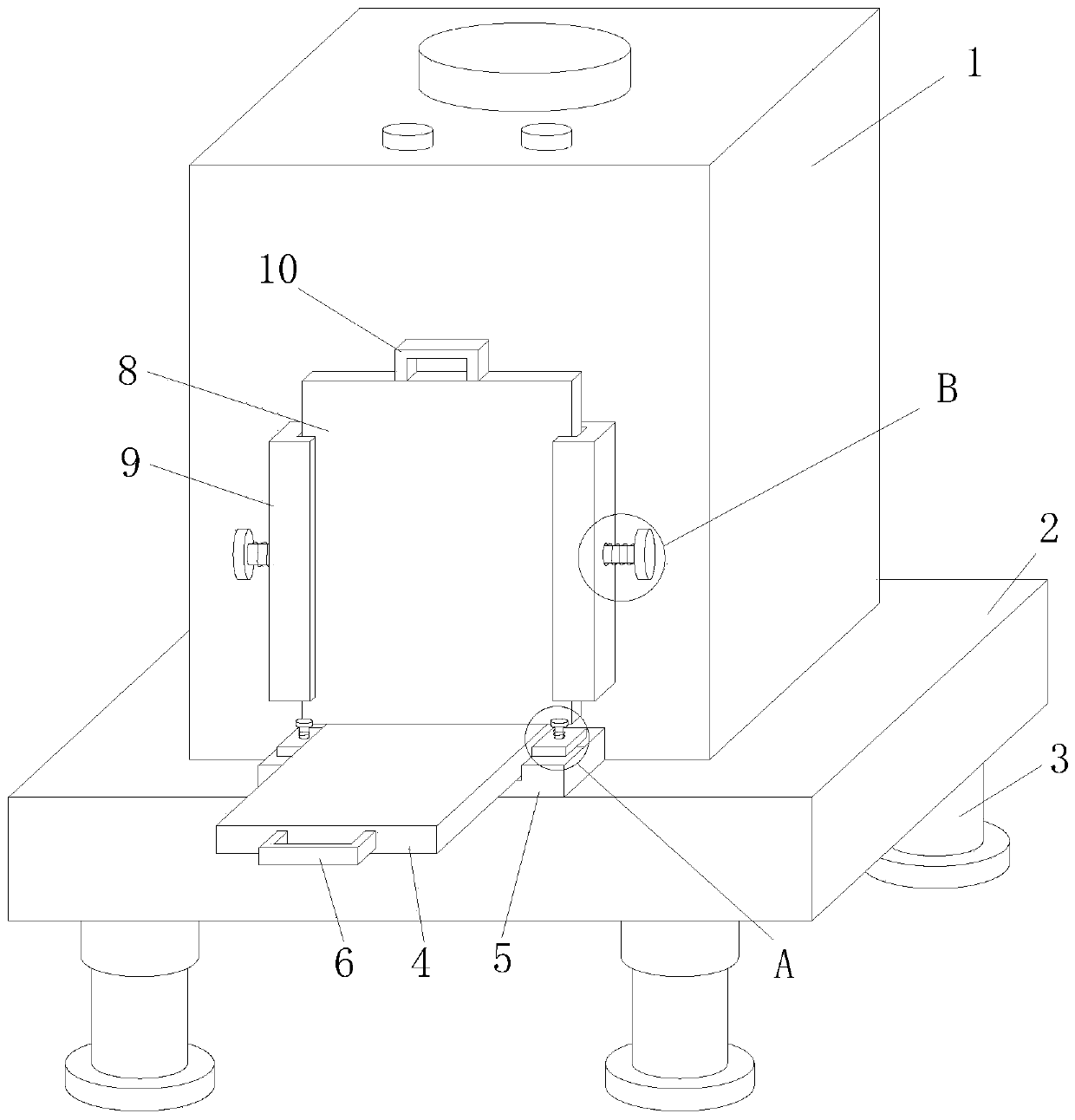

[0032] Attached below Figure 1-5 The present invention is further described with embodiment:

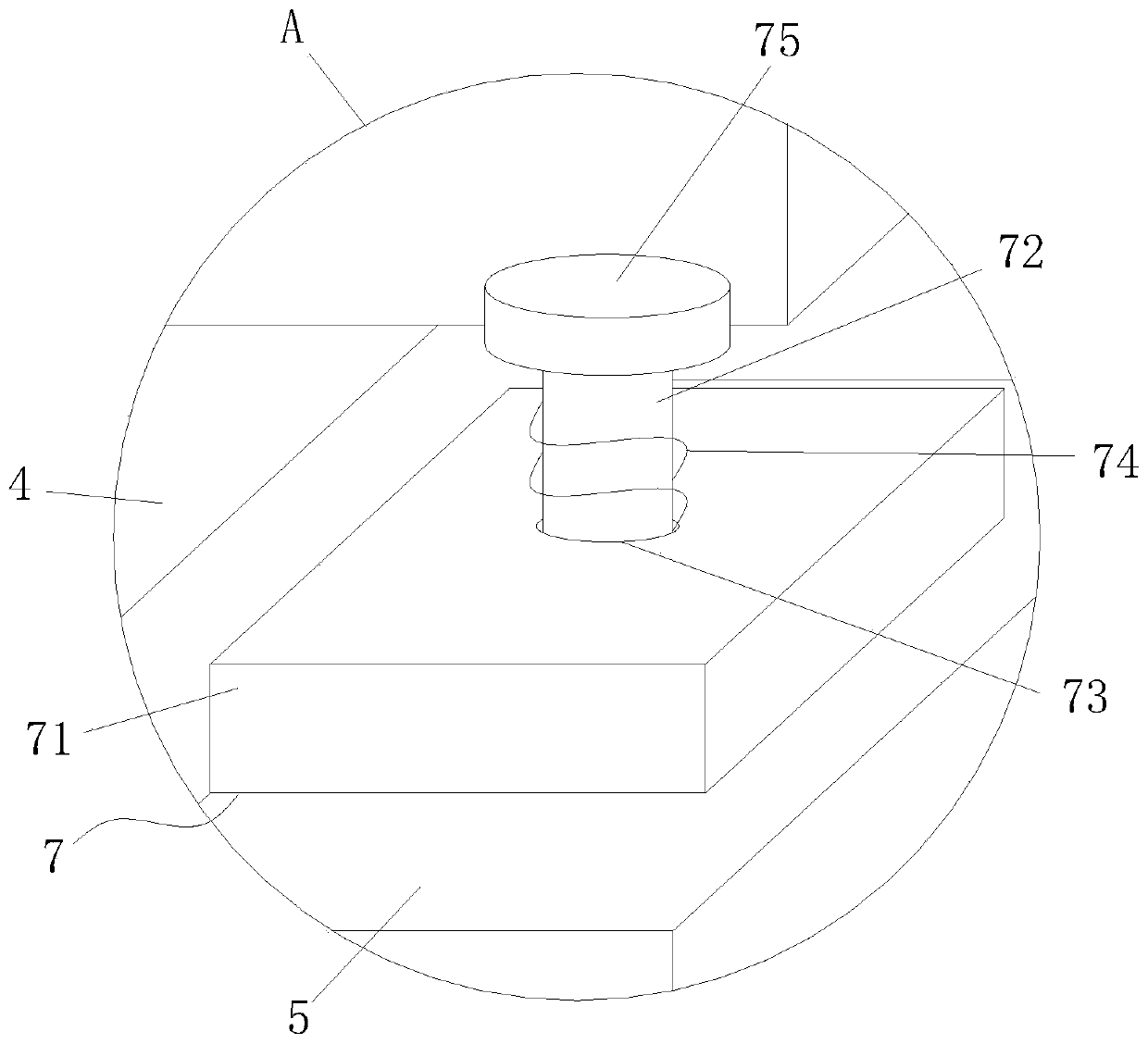

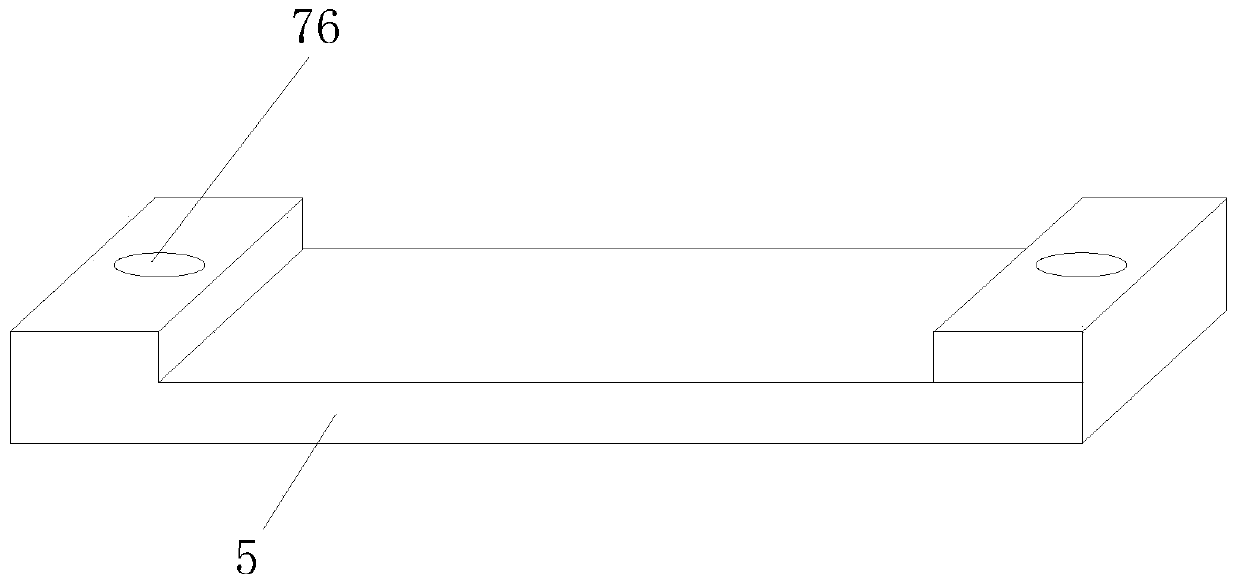

[0033] A polishing device for stainless steel tee joints, comprising a polishing box 1 and a placement plate 4, the polishing box 1 is fixed on the upper plate of the support base 2, and the lower plate of the support base 2 is connected with several support columns 3, and the placement plate 4 Movably inserted in the through hole provided on the front end of the polishing box 1, and the placement plate 4 is slidably arranged in the support chute 5, the support chute 5 is fixedly arranged on the upper plate of the support seat 2, and the placement plate 4 is provided with a tee Joint placement slots, and the first locking assembly 7 is arranged on both sides of the placement plate 4, and the existing brass three-way joint is replaced by a stainless steel three-way joint, so that when in use, the three-way joint can effectively avoid collisions. The fracture of the tee joint can pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com