Nitrogen-containing carbon material for supercapacitor, preparation method and application thereof

A technology of supercapacitors and electrode materials, applied in chemical instruments and methods, hybrid capacitor electrodes, carbon compounds, etc., can solve the problems of high production cost and small specific surface area, reduce cost input, increase specific surface area, and improve heterocyclic rings. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

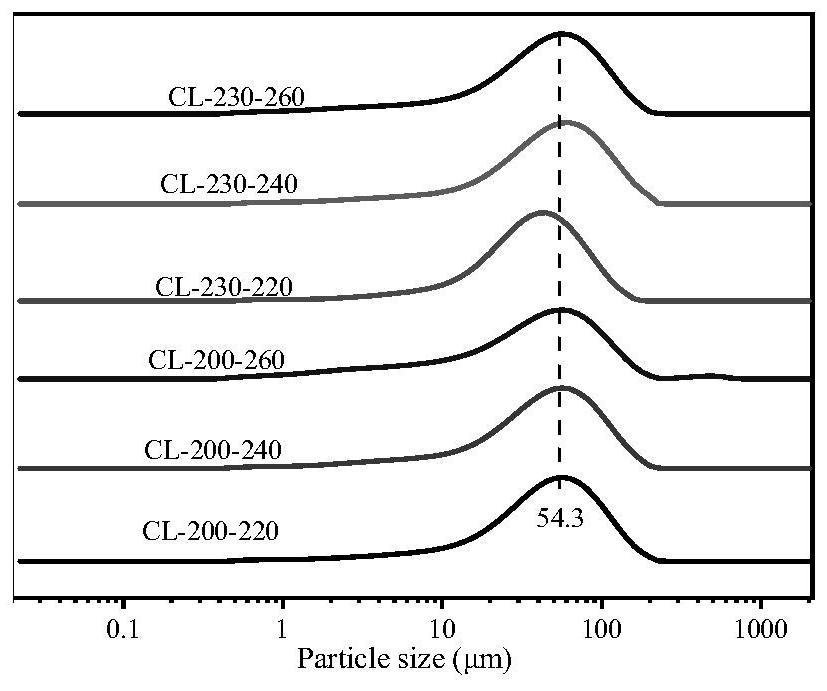

[0043] 1.1 Preparation of nitrogen-containing carbon materials for supercapacitors

[0044] 1) Preparation of the filtrate: add 6.6g of domestic sludge with a water content of 80% to 20mL of deionized water, and at the same time add 0.26g of solid sodium hydroxide, react in a 100mL hydrothermal reactor at 180°C for 1 hour, and separate the solid and liquid to obtain the filtrate; 2) Preparation of nitrogen-containing carbon products: In a hydrothermal reaction kettle, add 20mL of filtrate and 2g of cellulose at the same time, carry out hydrothermal reaction at 180°C, and the reaction time is 1h; after the reaction set time, further increase the temperature to continue the reaction , the reaction temperature is 280°C, and the reaction is 1h. After the reaction, the hydrothermal reaction product is suction-filtered, washed with deionized water, suction-filtered, ethanol-washed, and suction-filtered, and the treated product is vacuum-dried at 120°C for 12 hours to obtain a solid ...

Embodiment 2

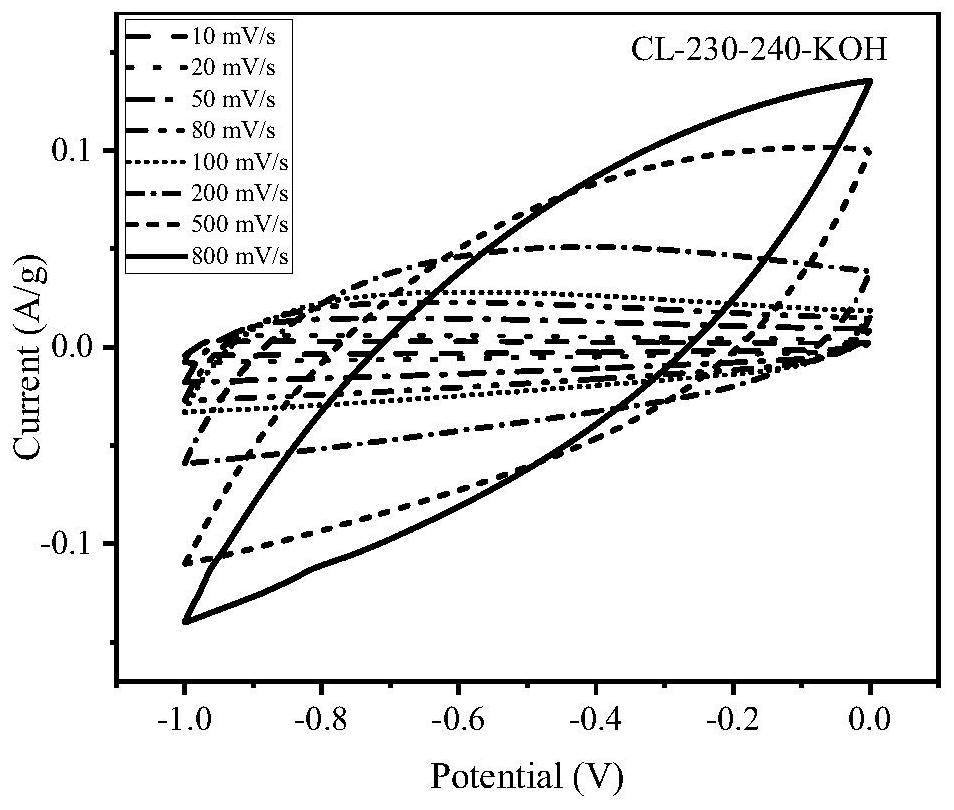

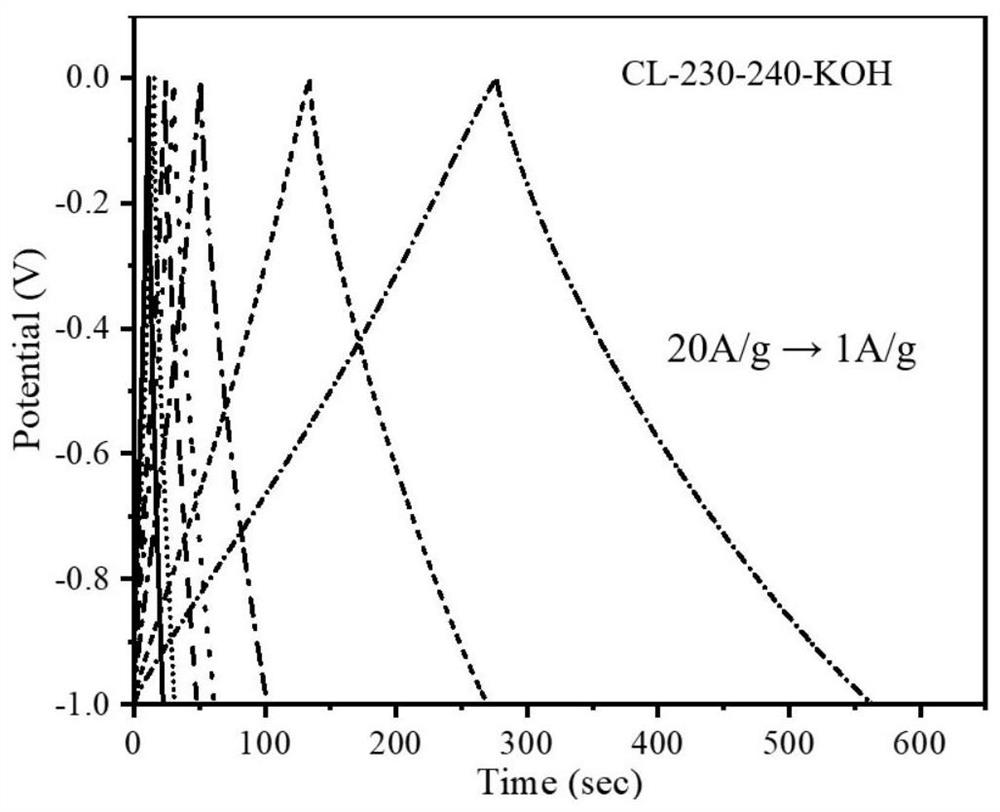

[0049] 2.1 Preparation of nitrogen-containing carbon materials for supercapacitors

[0050] 1) Preparation of the filtrate: add 20 g of domestic sludge with a water content of 80% to 20 mL of deionized water, and at the same time add 1 mL of 0.1 mol / L hydrochloric acid solution, react in a 100 mL hydrothermal reactor at 230 ° C for 2 h, and separate the solid and liquid to obtain the filtrate; 2) Preparation of nitrogen-containing carbon products: In a hydrothermal reaction kettle, add 20mL of filtrate and 4.0g of cellulose at the same time, carry out hydrothermal reaction at 240°C, and the reaction time is 2h; after the reaction set time, further increase the temperature and continue Reaction, the reaction temperature is 320°C, and the reaction is 3h. After the reaction, the hydrothermal reaction product is suction-filtered, washed with deionized water, suction-filtered, ethanol-washed, and suction-filtered, and the treated product is vacuum-dried at 120°C for 12 hours to obt...

Embodiment 3

[0055] 3.1 Preparation of nitrogen-containing carbon materials for supercapacitors

[0056] 1) Preparation of the filtrate: Add 40 g of domestic sludge with a water content of 80% to 20 mL of deionized water, and at the same time add 1 mL of 0.1 mol / L phosphoric acid solution, react in a 100 mL hydrothermal reactor at 260 ° C for 2 h, and separate the solid and liquid to obtain the filtrate; 2) Preparation of nitrogen-containing carbon products: In a hydrothermal reaction kettle, add 20mL of filtrate and 8.0g of cellulose at the same time, carry out hydrothermal reaction at 230°C, and the reaction time is 2h; after the reaction set time, further increase the temperature and continue Reaction, the reaction temperature is 240°C, and the reaction is 3h. After the reaction, the hydrothermal reaction product is suction-filtered, washed with deionized water, suction-filtered, ethanol-washed, and suction-filtered, and the treated product is vacuum-dried at 120°C for 12 hours to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com