Method for improving deformability of high-ductility concrete

A technology of high ductility concrete and capacity, which is applied in the field of building materials and high ductility concrete. It can solve the problems of increasing fiber cost, complex technology, and unfavorable tensile ductility of high ductility concrete materials, so as to avoid wear and improve interface performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

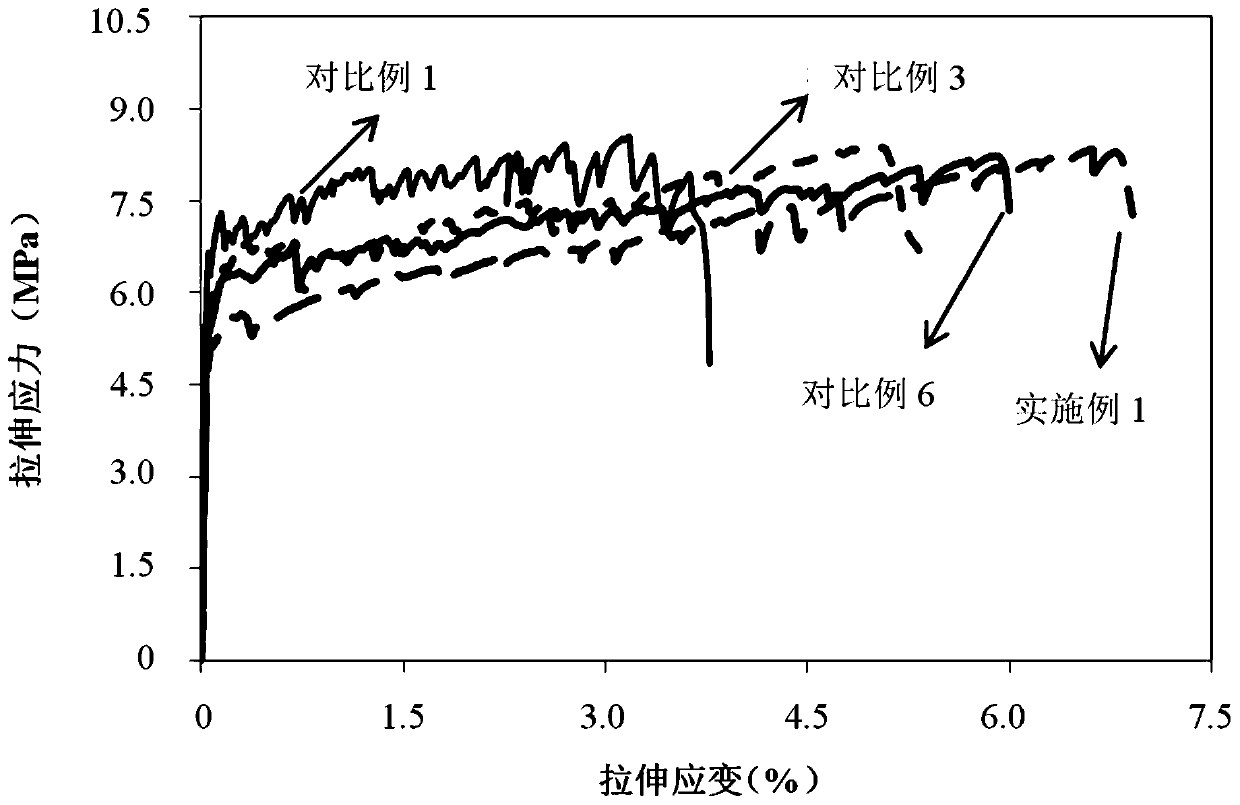

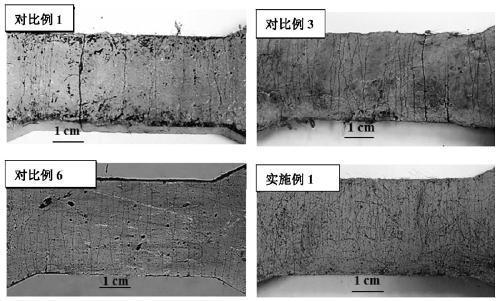

[0106] According to the traditional high ductility concrete material, the proportion of each raw material (by weight) is shown in Table 7.

[0107] Table 7

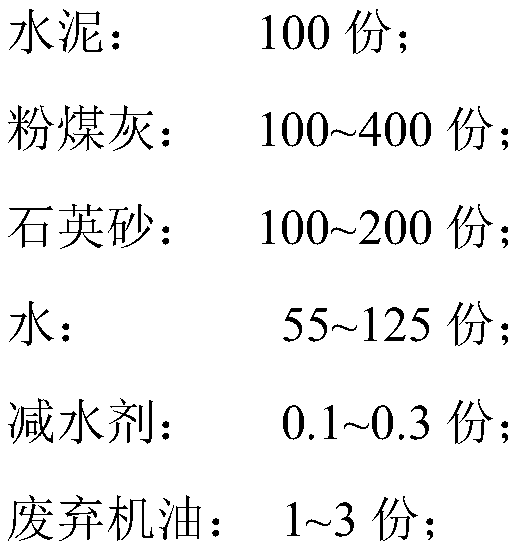

[0108] cement fly ash Quartz sand water Superplasticizer Modified PVA fiber waste oil 100 220 100 80 0.30 2.0% of the total volume of high ductility concrete 3 copies

[0109] Among them, the cement is ordinary Portland cement with a label of 52.5; the fly ash is a first-class fly ash, and the specific surface area is ≥800m 2 / kg, the density is 2.8g / cm 3 ;Quartz sand is made of standard sand; the water reducer is polycarboxylate high-efficiency water reducer; the nominal length of PVA fiber is 8-15mm, the equivalent diameter is 30-45μm, and the tensile strength is ≥1200N / mm 2 , The elongation at break is 3-5%.

[0110] Modified PVA fiber is modified by the following methods:

[0111] (1) Ultrasonic cleaning of PVA fibers with alcohol, then soaking in NaOH solution for 3 hours, dr...

Embodiment 2

[0121] The batching is carried out according to the traditional high ductility concrete material, and the ratio of each raw material (by weight) is shown in Table 8.

[0122] Table 8

[0123] cement fly ash Quartz sand water Superplasticizer Modified PVA fiber waste oil 100 100 200 55 0.10 1.5% of the total volume of high ductility concrete 3 copies

[0124] Among them, the cement is ordinary Portland cement with a label of 52.5; the fly ash is a first-class fly ash, and the specific surface area is ≥800m 2 / kg, the density is 2.8g / cm 3 ;Quartz sand is made of standard sand; the water reducer is polycarboxylate high-efficiency water reducer; the nominal length of PVA fiber is 8-15mm, the equivalent diameter is 30-45μm, and the tensile strength is ≥1200N / mm 2 , The elongation at break is 3-5%.

[0125] Modified PVA fiber is modified by the following methods:

[0126] (1) Ultrasonic cleaning of PVA fibers with alcohol, then soaking in Na...

Embodiment 3

[0136] According to the traditional high ductility concrete materials, the proportion of each raw material (by weight) is shown in Table 9.

[0137] Table 9

[0138] cement fly ash Quartz sand water Superplasticizer Modified PVA fiber waste oil 100 400 100 125 0.30 2.5% of the total volume of high ductility concrete 3 copies

[0139] Among them, the cement is ordinary Portland cement with a label of 52.5; the fly ash is a first-class fly ash, and the specific surface area is ≥800m 2 / kg, the density is 2.8g / cm 3 ;Quartz sand is made of standard sand; the water reducer is polycarboxylate high-efficiency water reducer; the nominal length of PVA fiber is 8-15mm, the equivalent diameter is 30-45μm, and the tensile strength is ≥1200N / mm 2 , The elongation at break is 3-5%.

[0140] Modified PVA fiber is modified by the following methods:

[0141] (1) Ultrasonic cleaning of PVA fibers with alcohol, then soaking in NaOH solution for 3 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com