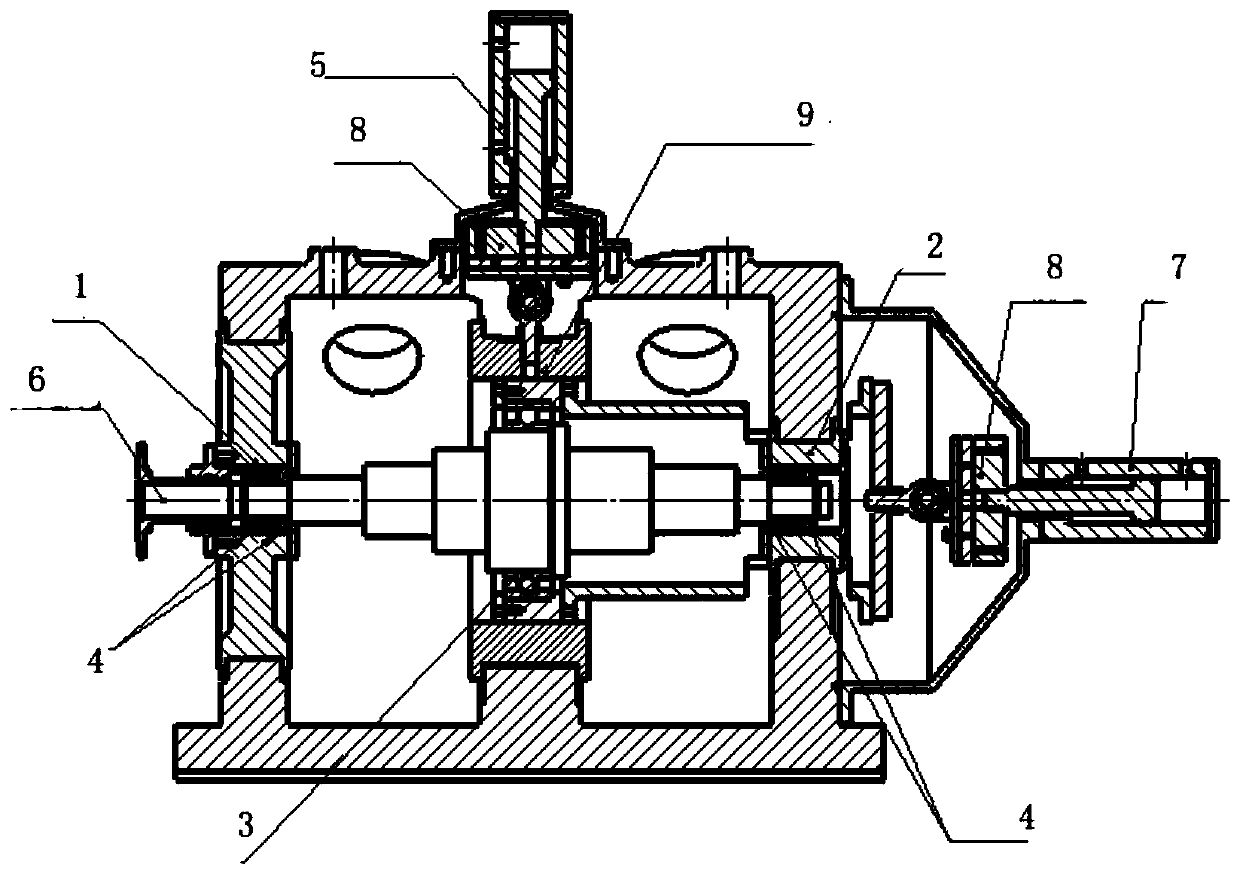

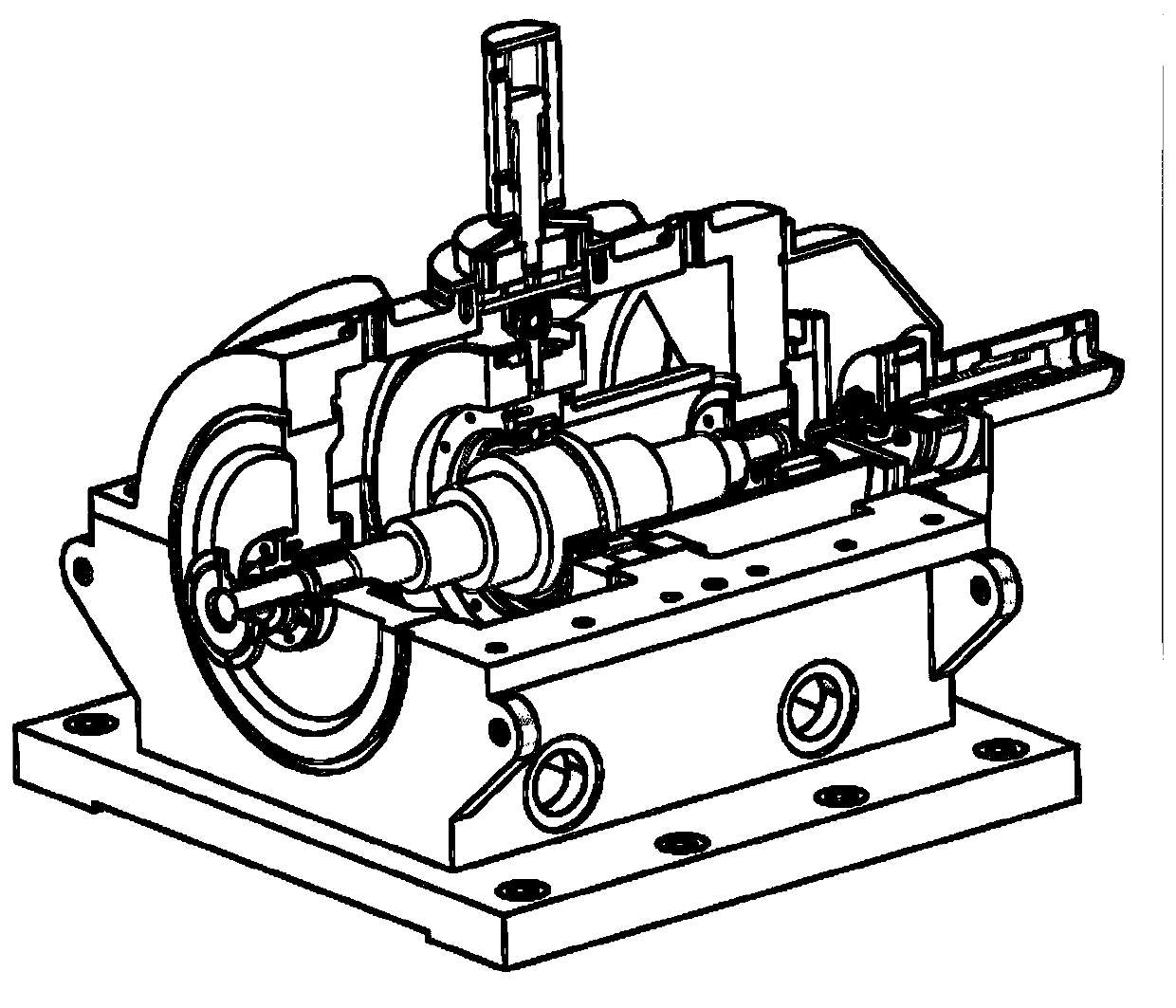

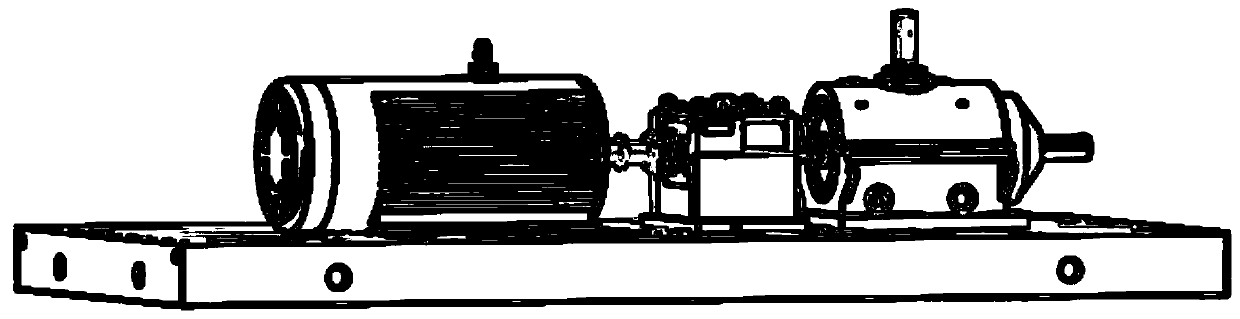

Main shaft bearing impact test bench

A technology of impact test and spindle bearing, which is applied in the field of aero-engines, can solve the problems of aero-engines not working normally, affecting the performance of aero-engines, harsh working environment, etc., and achieve the effects of prolonging the life of the test bench, authentic test results, and convenient safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0032] The difference between embodiment 2 and embodiment 1 is that the test bearings are arranged and loaded in different ways; in this embodiment, the radially loaded test bearing is arranged in the middle of the test shaft, and the axially loaded test bearing is arranged at the second fulcrum; switching between the above The two arrangement loading methods of the test bearing 3 can meet the requirements of the test function without changing the outer structure design of the casing, only need to make a different design for the bearing seat of the casing and equip the corresponding bearing bushing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com