A method and application of in situ heterostructure construction based on indium zinc sulfide nanosheets

A heterostructure and nanosheet technology, applied in chemical instruments and methods, carbon monoxide, physical/chemical process catalysts, etc., can solve the problems of 2D nanosheet heterostructure construction method and insufficient binding force, and achieve good popularization and application value. , The effect of simple process conditions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

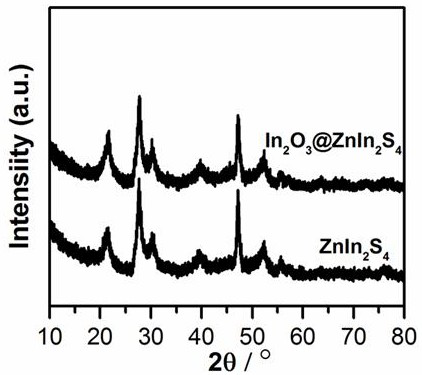

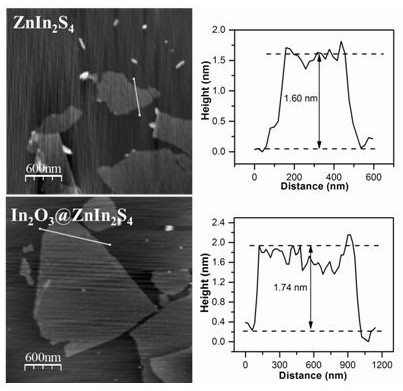

[0038] In 2 O 3 @ZnIn 2 S 4 Preparation of heterojunction:

[0039] (1) Weigh 87.8 mg of zinc acetate dihydrate (Zn(CH) with an electronic balance. 3 COO) 2 ·2H 2 O), 234.5 mg of indium chloride tetrahydrate (InCl 3 ·4H 2 O), 120 mg of thioacetamide (CH 3 CSNH 2 ), added to a mixed solution of 15 mL of deionized water and 15 mL of anhydrous ethanol, and magnetically stirred for 30 min at a stirring speed of 1000 rpm to obtain a uniformly dispersed reaction precursor;

[0040] (2) The reaction precursor solution was then transferred to a 50 mL PTFE-lined stainless steel autoclave, and the reaction was carried out at a constant temperature of 180 °C in a drying oven for 24 h. After the reaction was completed, it was cooled to room temperature with the furnace;

[0041] (3) Centrifuge the sample with a centrifuge to obtain a yellow solid powder at a speed of 10,000 rpm; wash it twice with deionized water and ethanol, respectively, and dry it in the air at 60 °C overnigh...

Embodiment 2

[0045] In(OH) 3 @ZnIn 2 S 4 Preparation of heterojunction:

[0046] (1) Weigh 87.8 mg of zinc acetate dihydrate (Zn(CH) with an electronic balance. 3 COO) 2 ·2H 2 O), 234.5 mg of indium chloride tetrahydrate (InCl 3 ·4H 2 O), 120 mg of thioacetamide (CH 3 CSNH 2 ), added to a mixed solution of 15 mL of deionized water and 15 mL of anhydrous ethanol, and magnetically stirred for 30 min at a stirring speed of 1000 rpm to obtain a uniformly dispersed reaction precursor;

[0047] (2) The reaction precursor solution was then transferred to a 50 mL PTFE-lined stainless steel autoclave, and the reaction was carried out at a constant temperature of 180 °C in a drying oven for 24 h. After the reaction was completed, it was cooled to room temperature with the furnace;

[0048] (3) Centrifuge the sample with a centrifuge to obtain a yellow solid powder at a speed of 10,000 rpm; wash it twice with deionized water and ethanol respectively, and dry it in the air at 60 °C overnight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com