Method for constructing in-situ heterostructure based on sulfur-indium-zinc nanosheet and application of in-situ heterostructure

A heterostructure and nanosheet technology, applied in chemical instruments and methods, carbon monoxide, catalysts for physical/chemical processes, etc., can solve the problems of 2D nanosheet heterostructure construction method and insufficient binding force, and achieve good popularization and application value. , the effect of high efficiency and simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

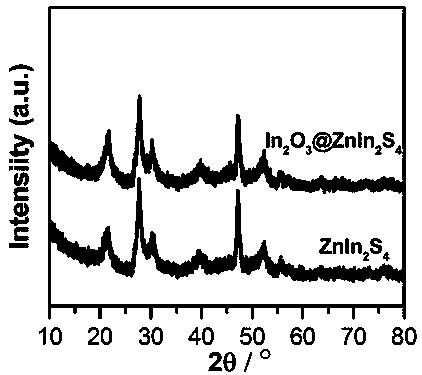

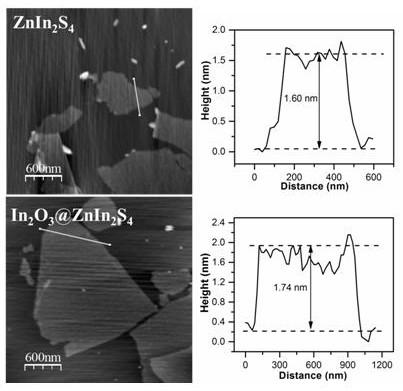

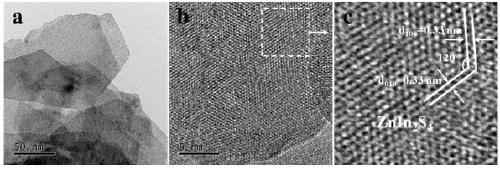

[0038] In 2 o 3 @ZnIn 2 S 4 Preparation of heterojunction:

[0039] (1) Weigh 87.8 mg of zinc acetate dihydrate (Zn(CH 3 COO) 2 2H 2 O), 234.5 mg of indium chloride tetrahydrate (InCl 3 4H 2 O), 120 mg of thioacetamide (CH 3 CSNH 2 ), added to a mixed solution of 15 mL deionized water and 15 mL absolute ethanol, magnetically stirred for 30 min, and the stirring speed was 1000 rpm to obtain a uniformly dispersed reaction precursor;

[0040] (2) Then the reaction precursor solution was transferred to a 50 mL polytetrafluoroethylene-lined stainless steel autoclave, and reacted at a constant temperature of 180 °C in a dry box for 24 h, and cooled to room temperature with the furnace after the reaction;

[0041] (3) The sample was centrifuged with a centrifuge to obtain a yellow solid powder at a rotational speed of 10,000 rpm; it was washed twice with deionized water and ethanol, and dried overnight at 60 °C in the air until the water was completely evaporated to obtain ...

Embodiment 2

[0045] In(OH) 3 @ZnIn 2 S 4 Preparation of heterojunction:

[0046] (1) Weigh 87.8 mg of zinc acetate dihydrate (Zn(CH 3 COO) 2 2H 2 O), 234.5 mg of indium chloride tetrahydrate (InCl 3 4H 2 O), 120 mg of thioacetamide (CH 3 CSNH 2 ), added to a mixed solution of 15 mL deionized water and 15 mL absolute ethanol, magnetically stirred for 30 min, and the stirring speed was 1000 rpm to obtain a uniformly dispersed reaction precursor;

[0047] (2) Then the reaction precursor solution was transferred to a 50 mL polytetrafluoroethylene-lined stainless steel autoclave, and reacted at a constant temperature of 180 °C in a dry box for 24 h, and cooled to room temperature with the furnace after the reaction;

[0048] (3) The sample was centrifuged with a centrifuge to obtain a yellow solid powder at a rotational speed of 10,000 rpm; washed twice with deionized water and ethanol respectively, and dried overnight at 60°C in air until the water was completely evaporated to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com