Turntable type automatic bearing cleaning production line that can be used for mixed production

A fully automatic technology for bearing cleaning, applied in liquid cleaning methods, cleaning methods and utensils, lighting and heating equipment, etc., can solve problems affecting success rate and accuracy, lack of cleaning process, complicated design, installation and maintenance, etc. Achieve the effects of avoiding the process of turning over, strong practicability, and high production line efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

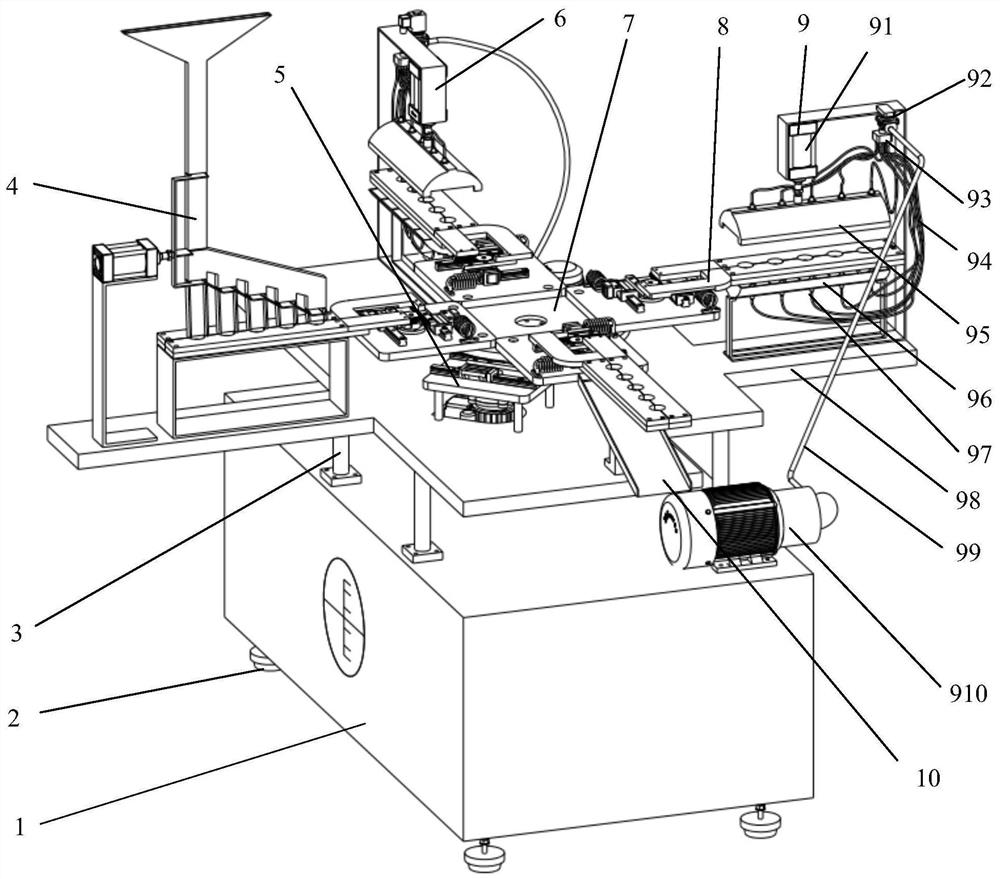

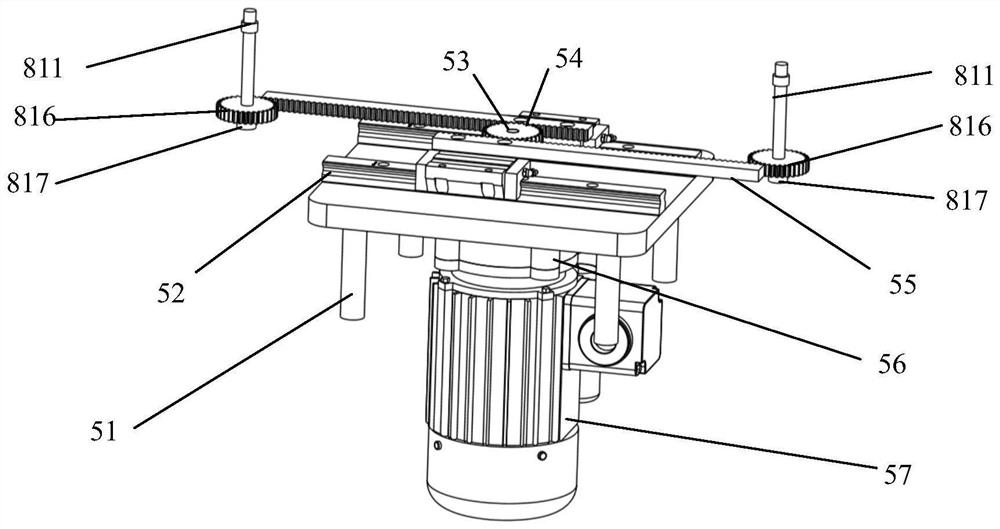

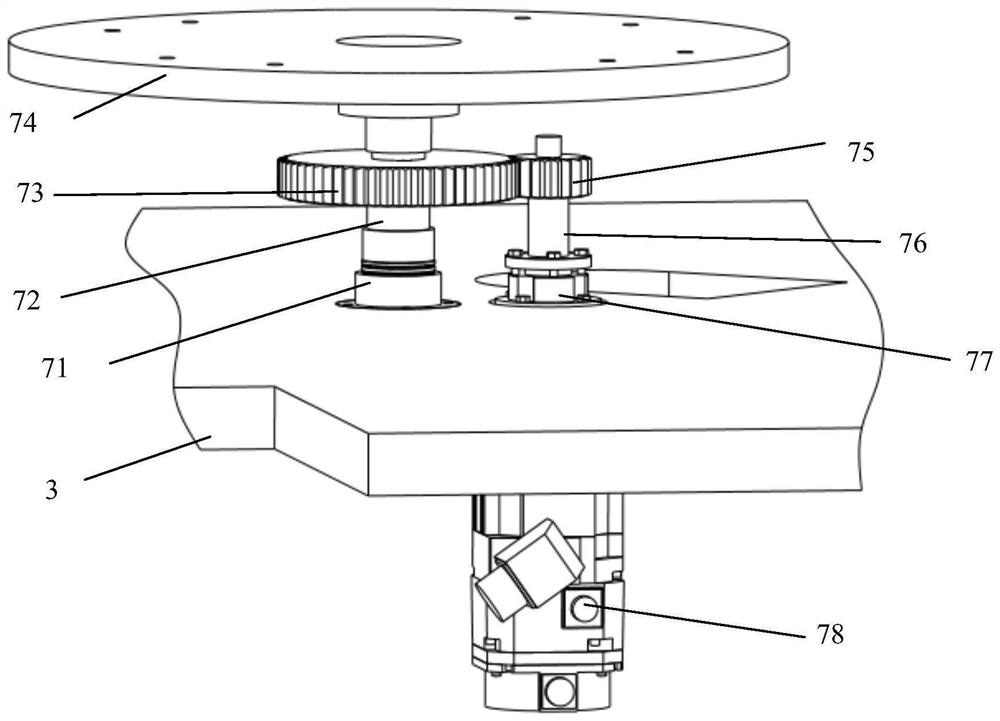

[0022] Such as Figure 1-8 As shown, the turntable-type automatic bearing cleaning production line of the present invention, which can be used for mixed-line production, includes a fuel tank 1, an anti-vibration tripod 2, a station frame 3, a feeding station group 4, and a jaw opening and closing control group 5. Cleaning station group 6, station rotating device 7, four identical bearing jaw devices 8, drying station group 9, and discharge inclined frame 10. It is characterized in that four anti-vibration tripods 2 are installed on the bottom of the oil tank 1 to fix it, the station frame 3 is installed on the oil tank 1 and the four sides are sequentially installed and fixed at 90° angle positions to fix the loading station group 4. Cleaning station group 6, drying station group 9 and discharge inclined frame 10, the four bearing jaw devices 8 are sequentially installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com