Intelligent two-end synchronous bending machine for pantograph carbon sliding plates and operating method of two-end synchronous bending machine

The technology of a pantograph carbon slide plate and a bending machine is applied in the field of carbon slide plate bending, which can solve the problems of increasing workload, reducing work efficiency, and reducing the number of finished carbon slide plates, and achieves the effect of improving work efficiency and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

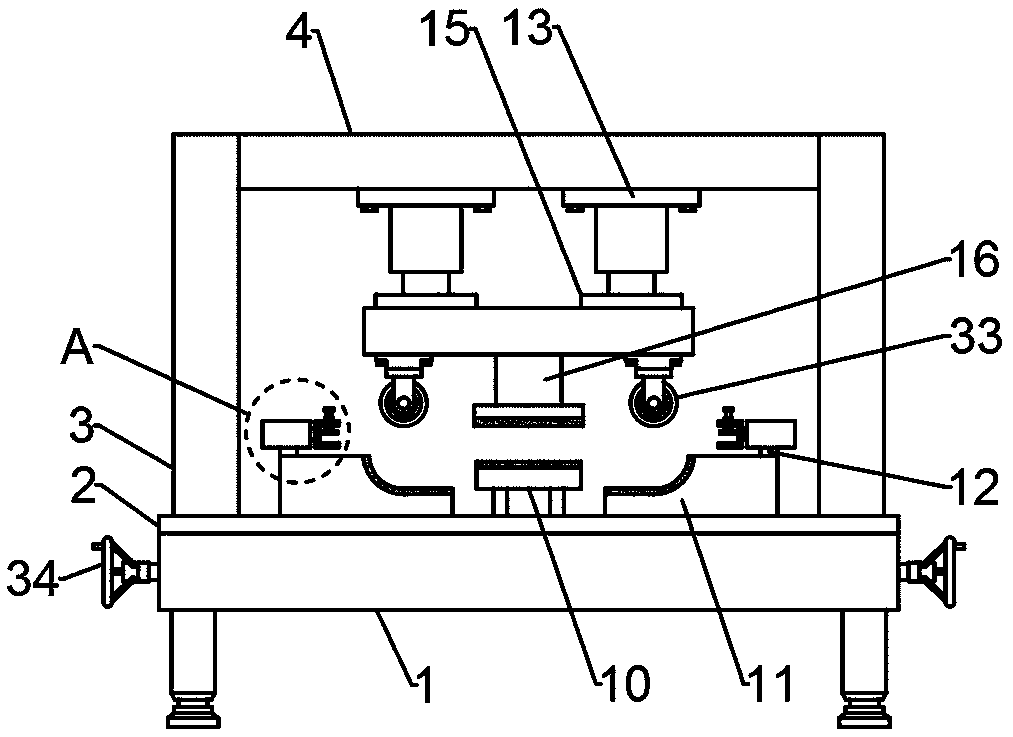

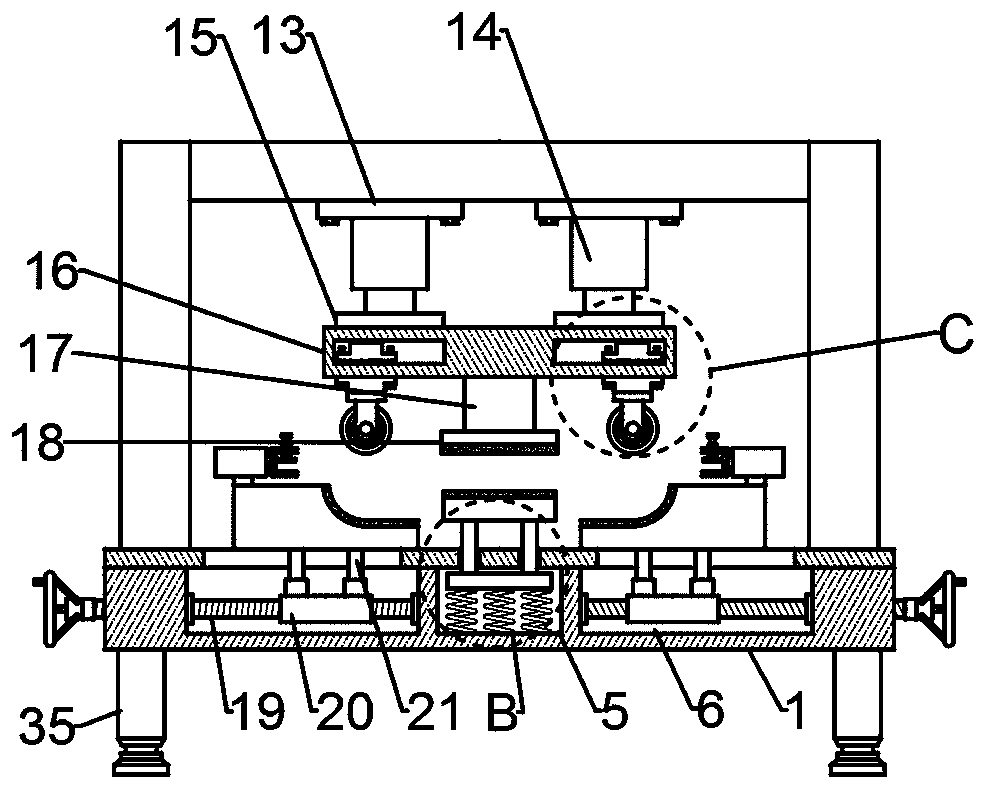

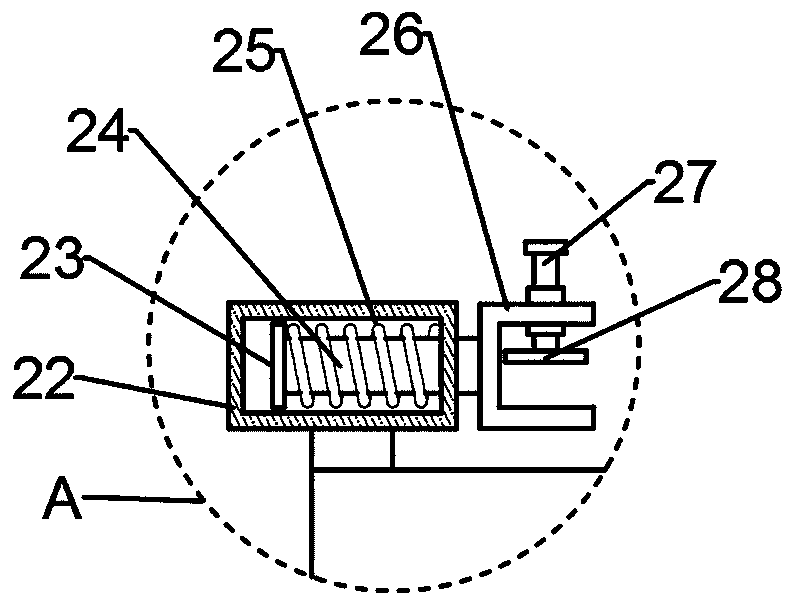

[0028] Example 1: see Figure 1-5, a synchronous bending machine with both ends for smart pantograph carbon skateboards, including a base 1 and a bottom plate 2, the base 1 and the bottom plate 2 are both rectangular plate-shaped horizontally arranged, and vertically set in the middle of the top surface of the base 1 There is a rectangular groove 5, and the top surface of the base 1 on both sides of the rectangular groove 5 is horizontally provided with an adjustment groove 6 of the same length; the bottom plate 2 is horizontally fixed on the top surface of the base 1; The middle part of both sides of the top surface of the base plate 2 is fixedly equipped with a vertically arranged column 3, and a horizontally arranged crossbeam 4 is fixedly connected between the tops of the two inner sides of the column 3; in the inside of the rectangular groove 5 A horizontal push plate 7 is movably installed, and some vertical springs 8 are fixedly installed on the bottom surface of the pu...

Embodiment 2

[0033] Example 2: see Image 6 , in this embodiment, the present invention also proposes an operation method for a synchronous bending machine at both ends of a smart pantograph carbon slide, including the following steps:

[0034] Step 1: First, each cylinder 14 is electrically connected to an external power supply through a wire, and the staff places the carbon skateboard bracket to be bent horizontally on the top surface of the bearing plate 10;

[0035] Step 2, adjust the position of the sliding block 11 according to the length of the carbon skateboard bracket to be bent, and drive the threaded rod 20 to rotate by turning the hand wheel 34, and drive the threaded sleeve 20 to move laterally on the rod body through the rotation of the threaded rod 20. The lateral movement of the threaded sleeve 20 drives the sliding block 11 at the top of the connecting rod 21 to move laterally on the bottom plate 2 for adjustment;

[0036] Step 3, by turning the fixing bolt 27 in the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com