Nitrogen-containing compound, electronic element, and electronic device

A nitrogen compound, chemical bond technology, used in electrical components, electrical solid devices, circuits, etc., can solve the problems of performance degradation of light-emitting devices, increase in operating voltage, and decrease in luminous efficiency, and achieve good thermal stability, high melting point, and reinforcing materials. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

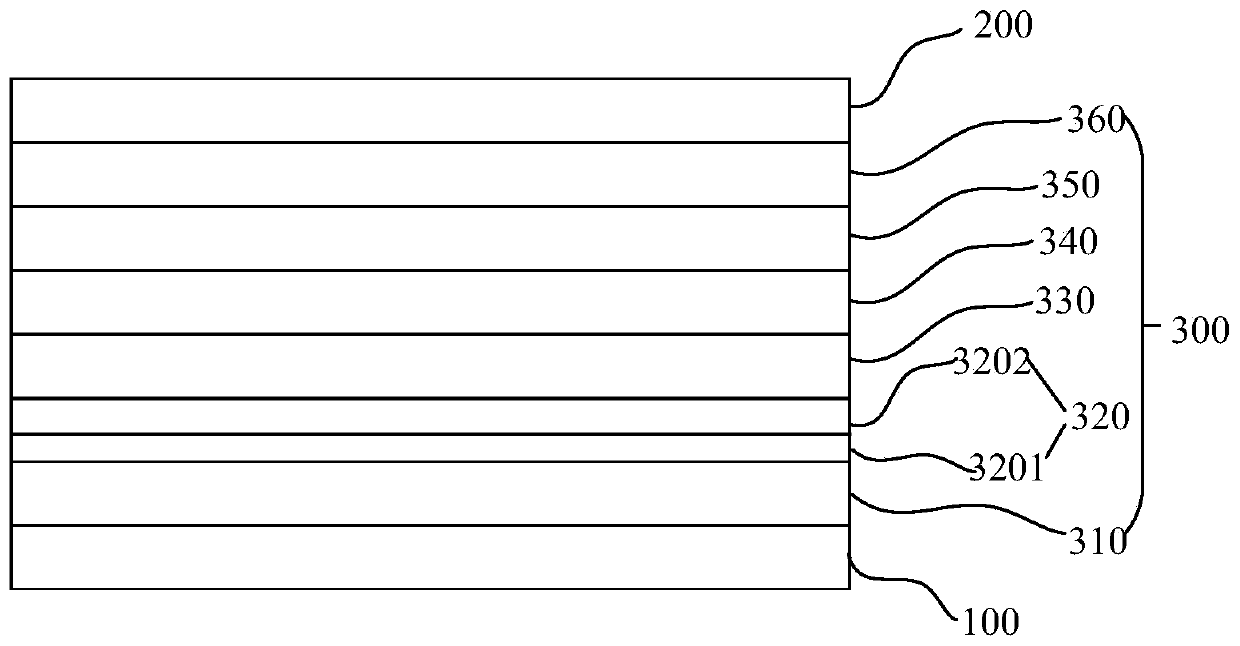

[0156] The anode was prepared by the following process: the thickness was The ITO substrate (manufactured by Corning) was cut into a size of 40mm × 40mm × 0.7mm, and it was prepared into an experimental substrate with cathode, anode and insulating layer patterns by using a photolithography process, using ultraviolet ozone and O 2 :N 2 Plasma surface treatment to increase the work function of the anode (experimental substrate), and then clean the experimental substrate; vacuum evaporation HAT-CN on the experimental substrate (anode) to form a thickness of The hole injection layer (HIL); on the hole injection layer (HIL), compound 1 is vacuum evaporated to form a thickness of The hole transport layer (HTL); TCTA is evaporated on the hole transport layer (HTL) to form a thickness of The hole-assisting layer; on the hole-assisting layer, vapor-deposit CBP as the host, while doping 3% Ir(piq) 2 (acac), forming a thickness of TPBi and LiQ prepared above are mixed according ...

Embodiment 2-23

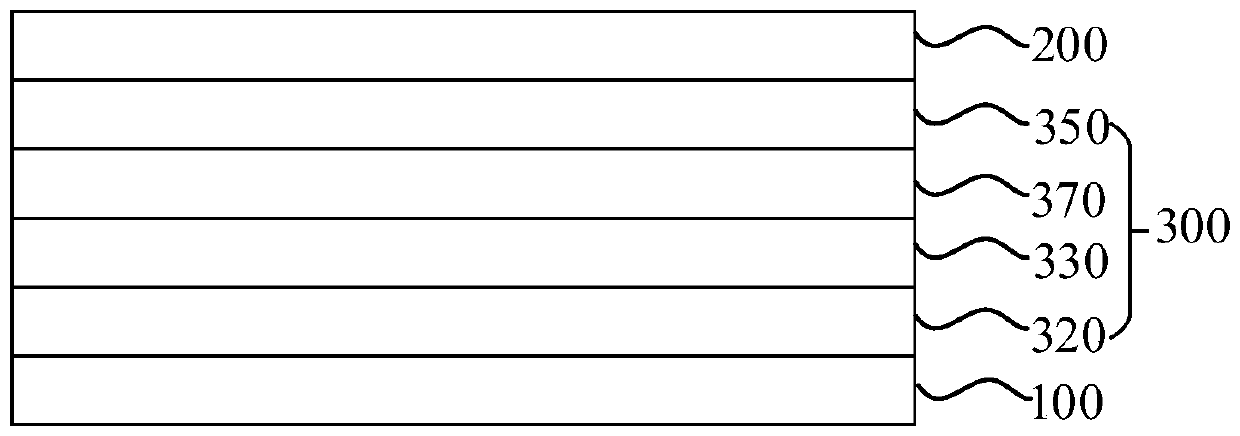

[0161] An organic electroluminescent device was fabricated by the same method as in Example 1, except that the compounds shown in Table 2 were each used in forming the hole transport layer. The device performance is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com