A green light host material, organic electroluminescent device and electronic display device

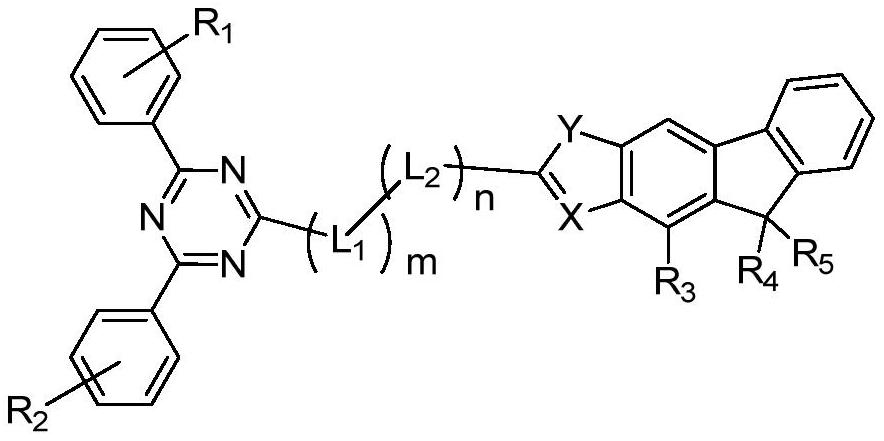

A main material, green light technology, applied in the field of green light main materials, organic electroluminescent devices and electronic display equipment, to achieve good solubility, reduce power consumption, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

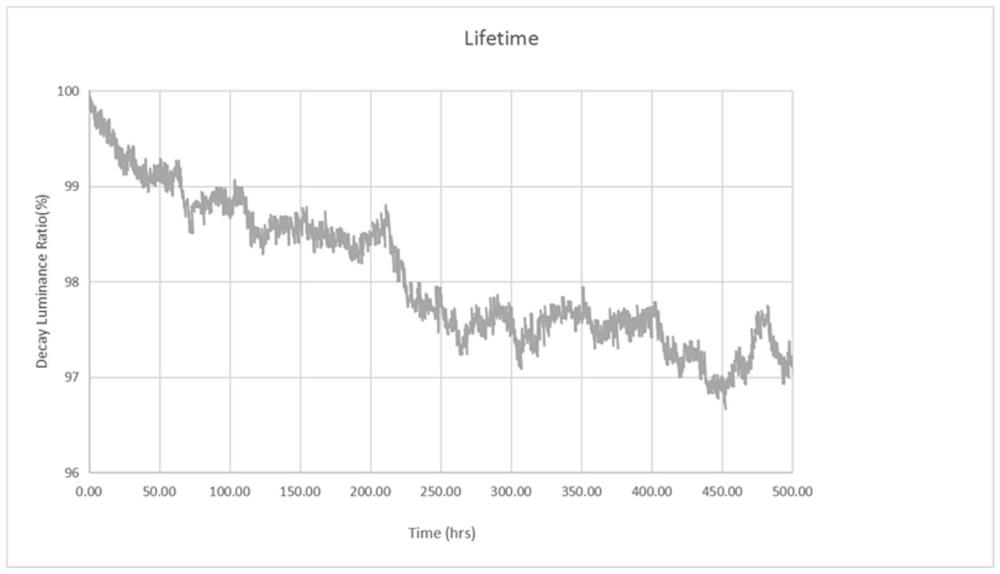

Image

Examples

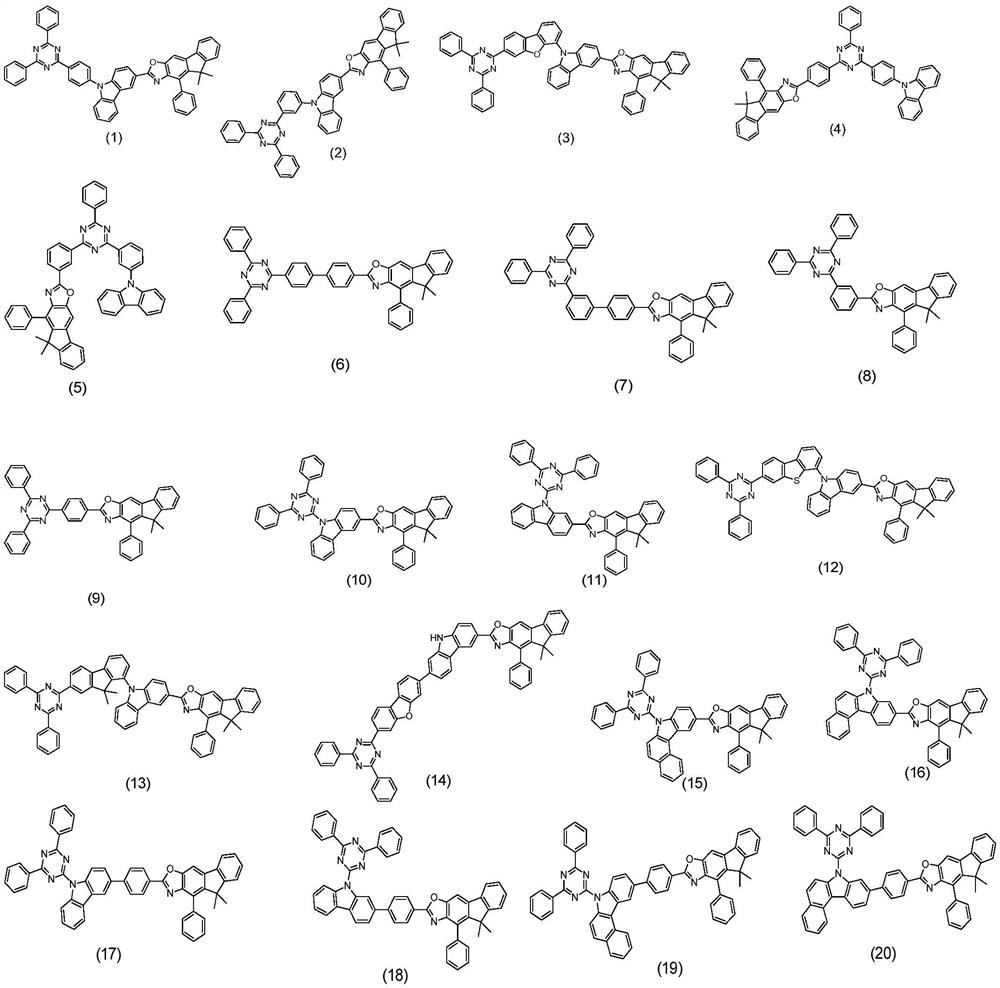

Embodiment 1

[0046]

[0047] The specific synthesis method of the green light host material (1) is as follows:

(1)

[0048]

[0049] Compound 1 (1eq, 314.76g / mol, 31.77mmol, 10.0g), compound 2 (2.1eq, 122.05g / mol, 66.72mmol, 8.14g), tetrakis (triphenylphosphine) palladium (0.05eq, 1155.58g / mol, 1.59mol, 1.84g) and potassium carbonate (1.6eq, 138.21g / mol, 50.83mol, 7.03g) were placed in a 300ml round bottom flask, to which was added toluene (100ml, with the v / m of compound 1 =10), ethanol (10ml, v / m=1 with compound 1) and water (50ml, v / m=5 with compound 1), the mixture was heated to reflux and stirred for 12h. After the reaction was complete, the reactor Cool to room temperature, filter, wash the filter cake with water and dry it, then add it to toluene and heat up to reflux for boiling and refining for 1h, after hot filtration, the filter cake is dried to obtain compound 3 (8.95g, yield 90.6%), MS ( EI): 311 (M+).

(2)

[0050]

[0051] Compound 3 (1eq, 311g / mol, 25.72mmol,...

Embodiment 2

[0053]

[0054] The specific synthesis method of the green light host material (2) is as follows:

[0055] Step 1 is basically the same as Embodiment 1, and all the other steps are as follows

(2)

[0056]

[0057] Compound 3 (1eq, 311g / mol, 25.72mmol, 8.0g), compound 5 (1.1eq, 596.23g / mol, 28.29mmol, 16.87g), tetrakis (triphenylphosphine) palladium (0.05eq, 1155.58g / mol, 1.29mol, 1.49g) and potassium carbonate (1.6eq, 138.21g / mol, 41.15mol, 5.69g) are placed in the round bottom flask of 300ml, add toluene (80ml, the v / m= 10), ethanol (8ml, v / m=1 with compound 3) and water (40ml, v / m=5 with compound 3), heat the mixture to reflux and stir the reaction for 12h, after the reaction is completed, the reactor is cooled to room temperature, filter, wash the filter cake with water and dry it, then add it to toluene and heat it up to reflux, cook and refine it for 1 hour, after hot filtration, dry the filter cake to obtain the green light main material (2) (16.84g, yield 83.6...

Embodiment 3

[0059]

[0060] The specific synthesis method of the green light host material (3) is as follows:

[0061] Step 1 is basically the same as Embodiment 1, and all the other steps are as follows

(2)

[0062]

[0063] Compound 3 (1eq, 311g / mol, 25.72mmol, 8.0g), compound 6 (1.1eq, 686.24g / mol, 28.29mmol, 19.41g), tetrakis (triphenylphosphine) palladium (0.05eq, 1155.58g / mol, 1.29mol, 1.49g) and potassium carbonate (1.6eq, 138.21g / mol, 41.15mol, 5.69g) are placed in the round bottom flask of 300ml, add toluene (80ml, the v / m= 10), ethanol (8ml, v / m=1 with compound 3) and water (40ml, v / m=5 with compound 3), heat the mixture to reflux and stir the reaction for 12h, after the reaction is completed, the reactor is cooled to room temperature, filter, wash the filter cake with water and dry it, then add it to toluene and heat it up to reflux, cook and refine it for 1 hour, after hot filtration, dry the filter cake to obtain the green light main material (3) (18.50g, yield 82.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com