Method for inserting a false twist into a thread and spinning machine and device for inserting a false twist into a thread

A spinning machine and yarn technology, applied in the field of devices implementing the method, can solve the problems that the spinning stability is not obviously improved, and achieve the effect of improving the spinning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

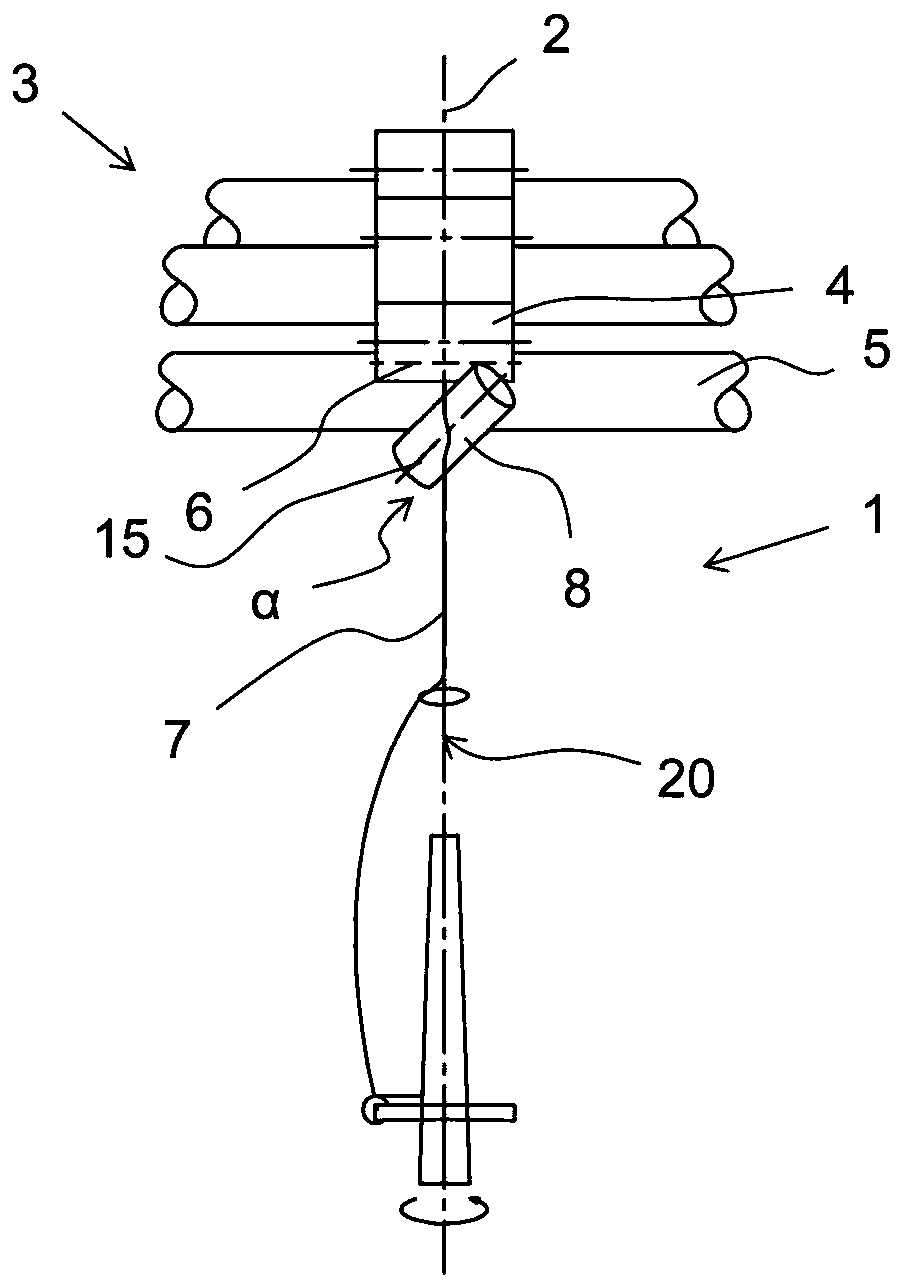

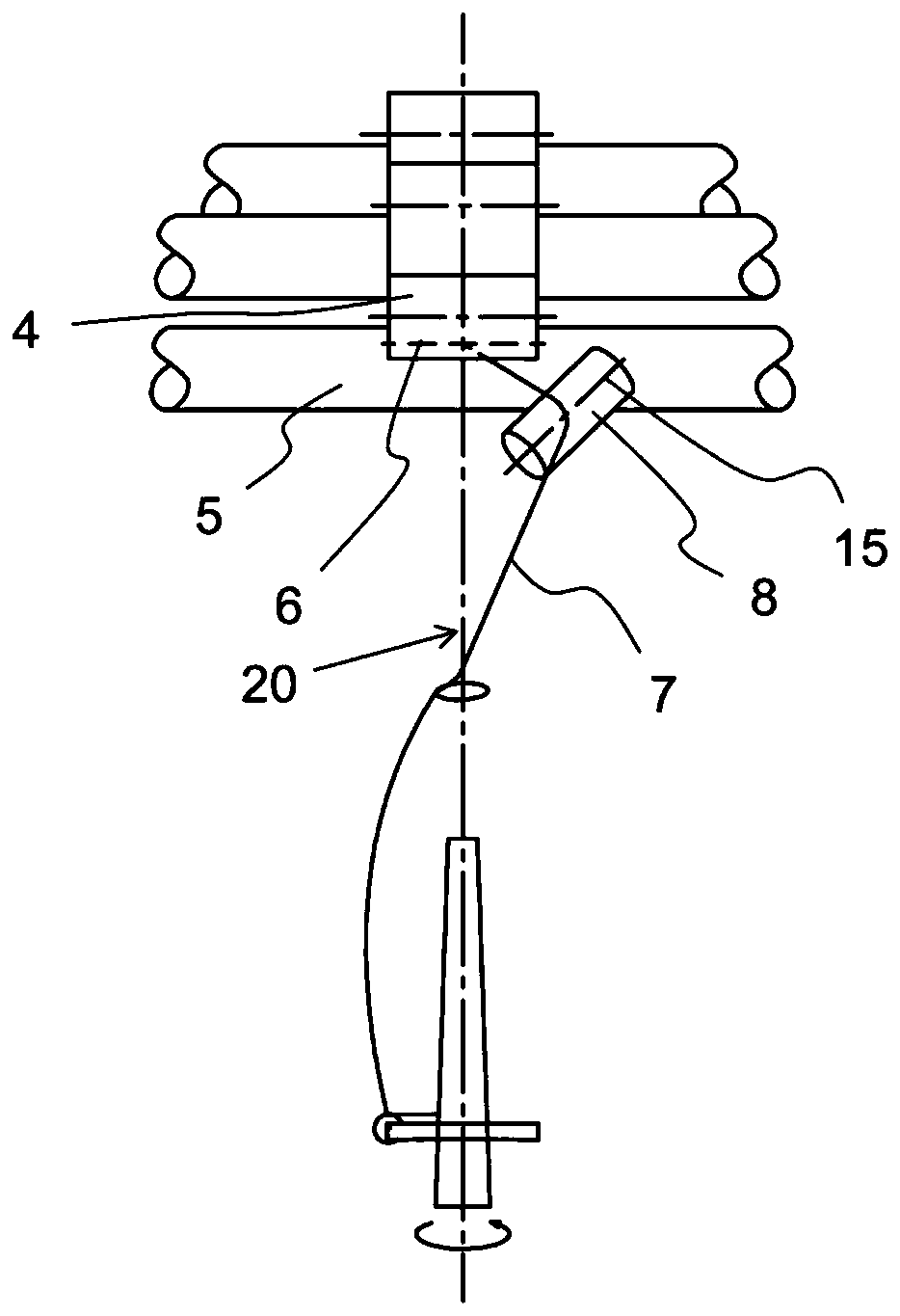

[0040] In the following description of the alternative exemplary embodiment, the same reference numerals are used for features that are identical and / or at least similar in terms of their design and / or mode of operation compared to the other exemplary embodiments. As long as these features are not explained again in detail, their configuration and / or mode of operation correspond to those of the features already described above. The mentioned rollers can have different outer sides, which are in particular cylindrical, conical or parabolic, even though only cylinders are mentioned in individual cases.

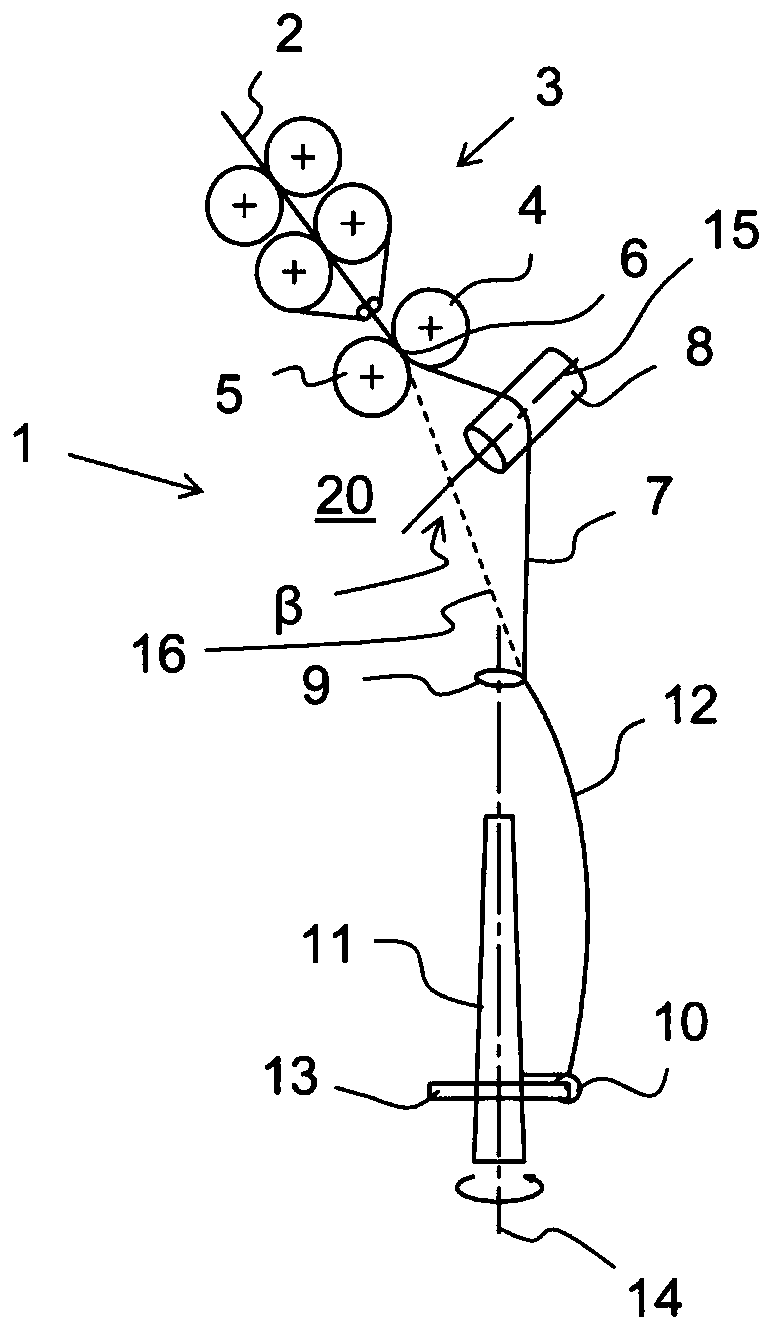

[0041] figure 1 A side view of the spinning position 1 of the ring spinning machine is shown. The fiber strand 2 passes through a drafting device 3 and is drawn there. The fiber strands leave the drafting device 3 at a roller pair formed by an upper roller 4 and a lower roller 5 . The upper roller 4 and the lower roller 5 form an output clamping station 6 in which the fiber st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com