High-strength, large-size and strong-constraint cable bent tower concrete crack control method

A control method and technology for concrete cracking, applied to buildings, bridges, bridge parts, etc., can solve the problems of unreasonable anti-cracking structure design of structural systems, hidden dangers of engineering, inappropriate maintenance methods of construction technology, etc. The effect of reducing concentrated heat release and avoiding temperature shrinkage cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

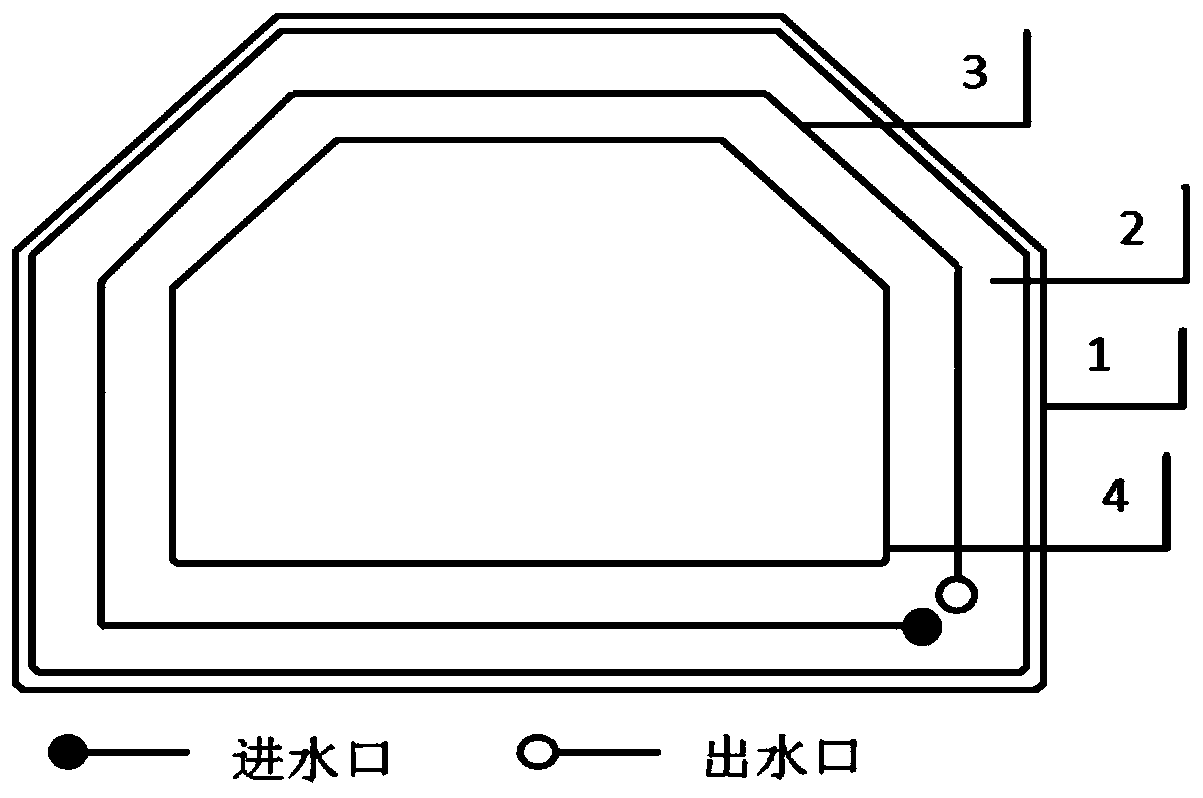

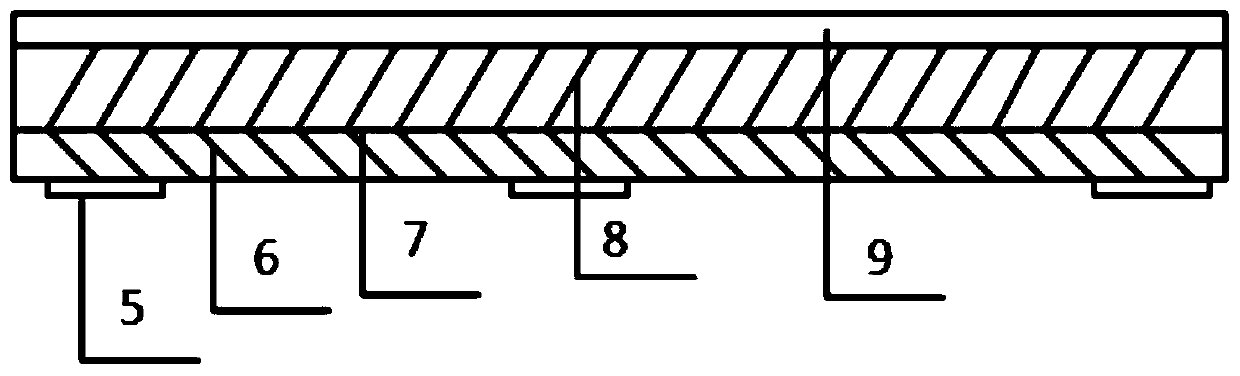

Image

Examples

Embodiment

[0052] The cable tower of a certain project is 330m high, and the tower body is made of C60 concrete. The length of the tower column along the bridge is 14-21m. 16.7m, the wall thickness of the tower column along the bridge is 1.2-1.7m, the wall thickness of the tower column and the bridge is 1.5-2.5m, and the wall thickness of the local position gradually changes from 3m to 1.8m. 60d strength assessment and acceptance, concrete pouring construction has gone through four different seasons, combined with previous engineering experience, the risk of concrete cracking of the cable tower is extremely high, and there is currently a phenomenon that there is no tower without cracking, so it is necessary to improve the overall crack resistance of the concrete structure of the cable tower. Problems of today's world. It mainly includes the following steps:

[0053] First, based on the concrete "hydration-temperature-humidity-constraint" multi-field coupling mechanism and model, the cra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com