Method for installing upper fixed joint of clean ceiling of electronic workshop

A technology for electronic workshops and installation methods, which is applied in the direction of ceilings, electrical components, building components, etc., and can solve the problems of affecting the verticality of the lower hanging system, construction deviation, and failure to install, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

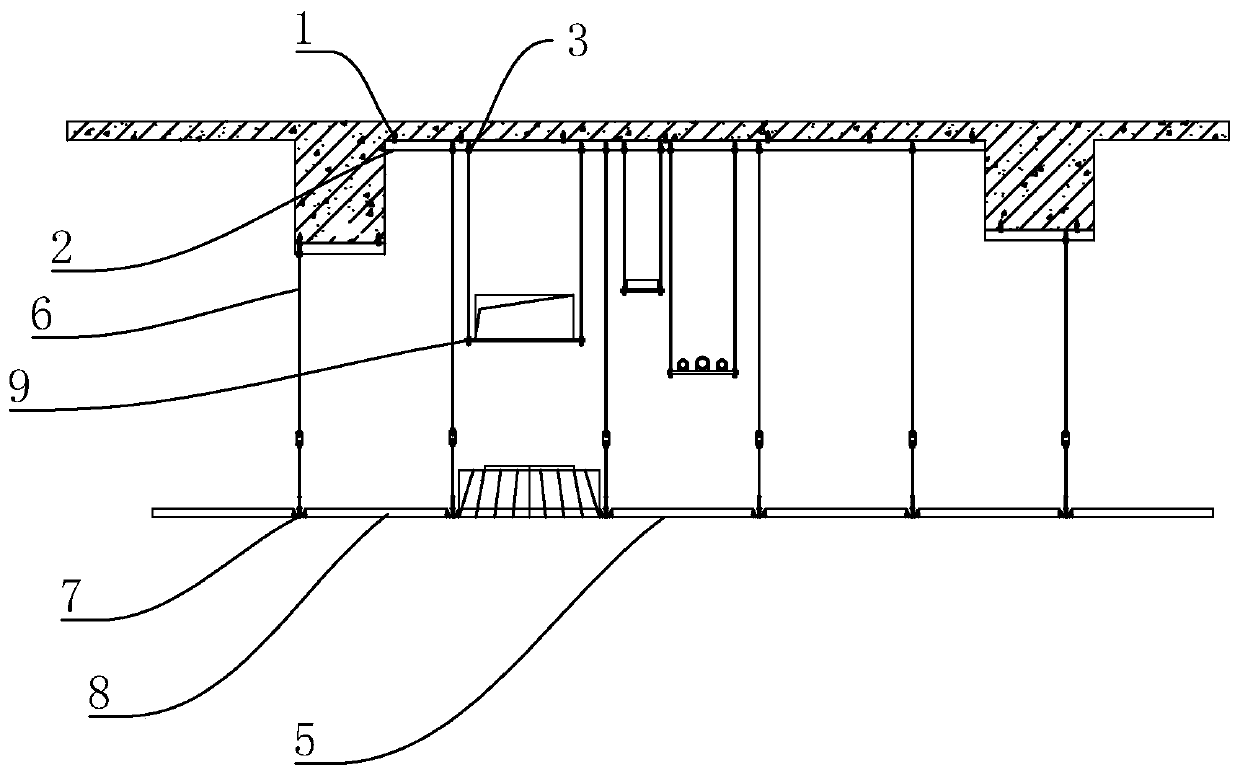

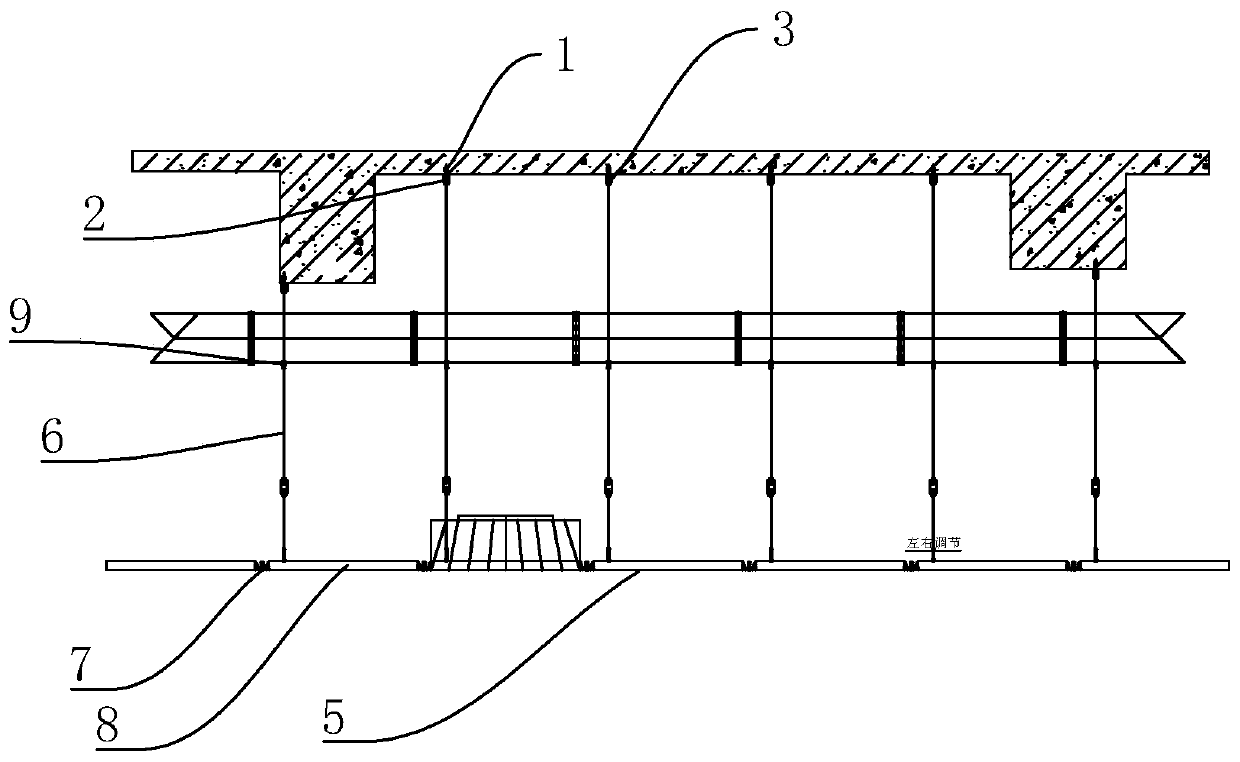

[0026] Embodiment 1: A method for installing fixed nodes on the upper part of the clean ceiling 5 of an electronic factory building, such as figure 1 and figure 2 shown, including the following installation steps:

[0027] S01, set out the line at the bottom of the structural floor, and install the C-shaped steel 2 with the anchor bolt 1;

[0028] S02, install the screw rod of the ceiling 5 through the spring nut 3 in the lower notch of the C-shaped steel 2;

[0029] S03, adjust the position of the boom 6 in the X direction of the lower notch of the C-shaped steel 2 according to the arrangement of the ceiling 5 boards;

[0030] S04, install the connecting piece 7 on the lower part of the suspender 6, and fix it with the keel of the ceiling 5 through the connecting piece 7, so as to realize the Y direction adjustment;

[0031] S05, in the suspended ceiling 5, install the MEP mechanical and electrical pipeline support 9, and the suspended ceiling 5 is fixed with the C-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com