Fired high-alkali coal slagging contamination prevention and control method based on boiler zone control

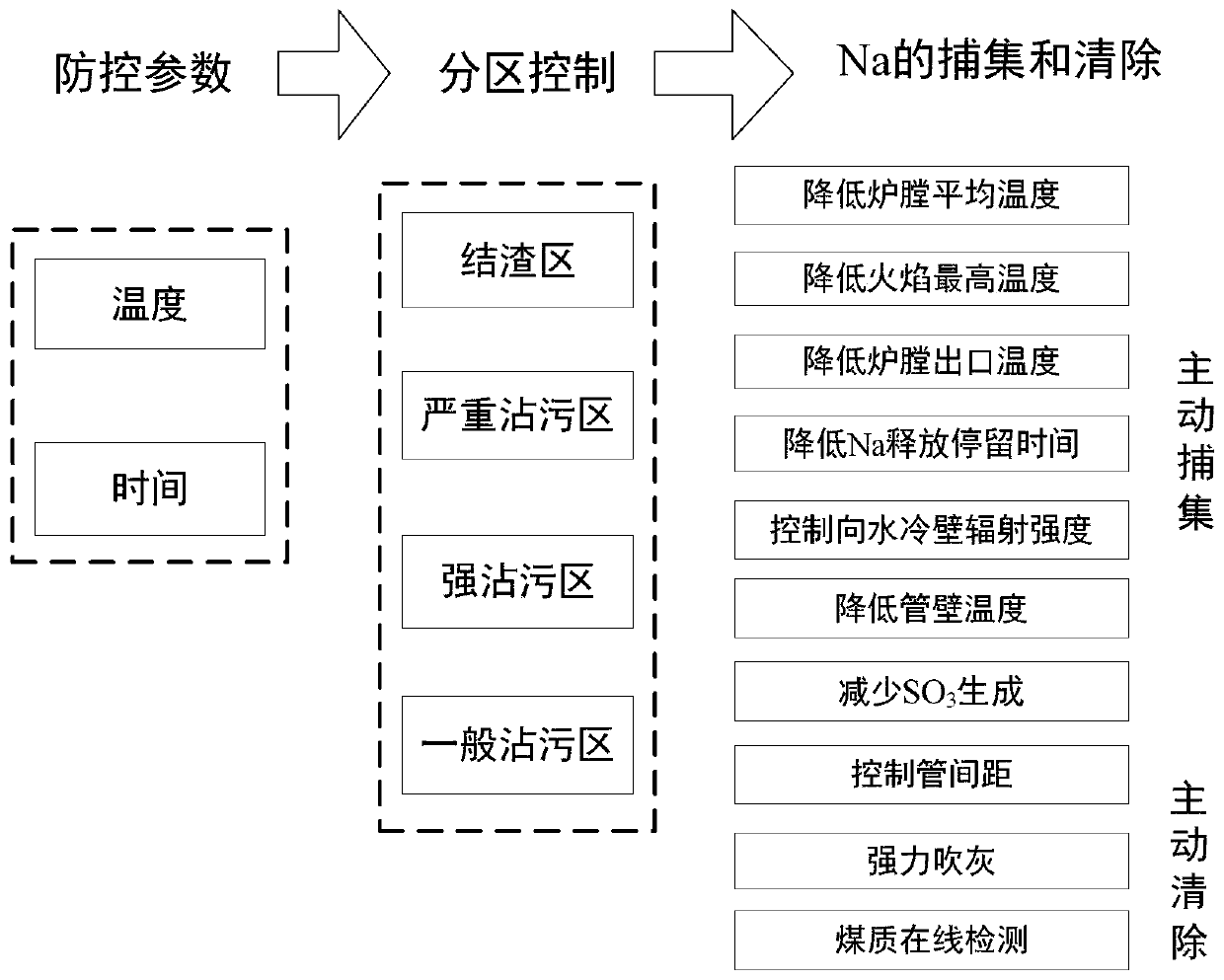

A technology of zone control and high alkali coal, which is applied in the control of combustion, combustion method, and the use of various fuels for combustion, etc., which can solve the problems of safe operation of unit equipment, pollution and ash accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

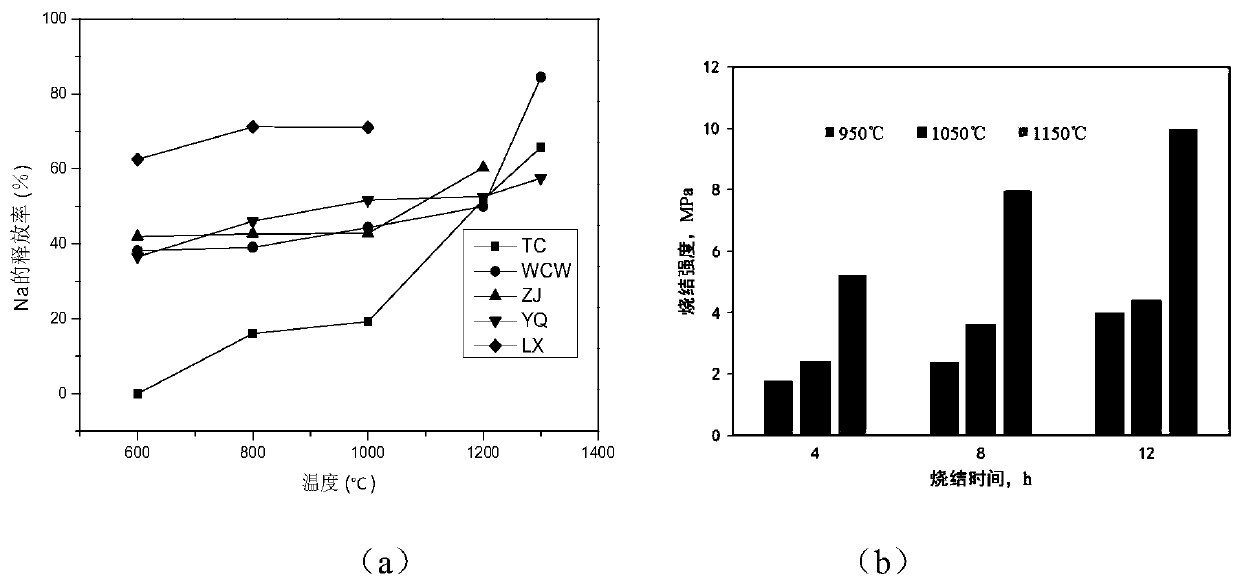

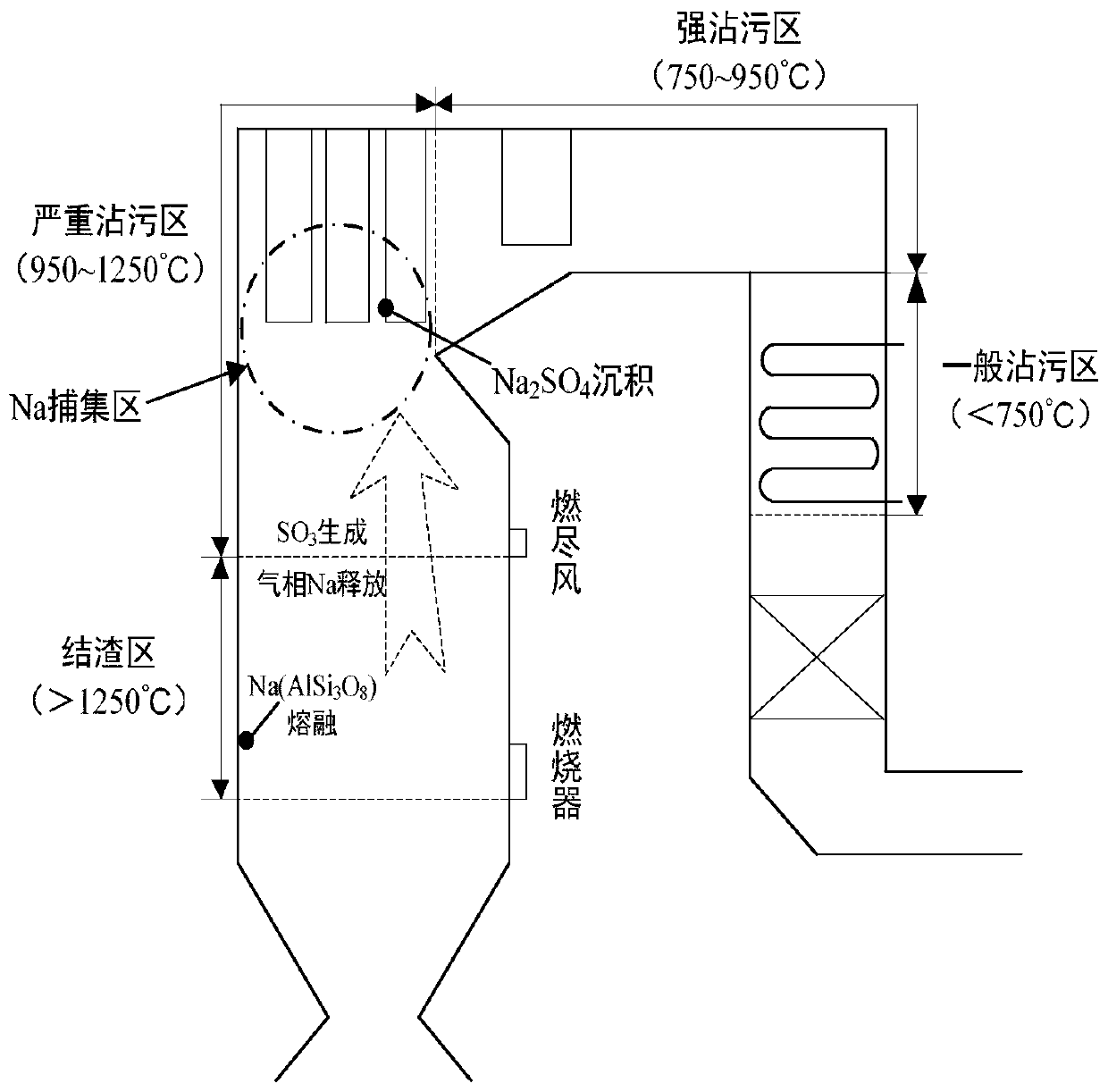

[0028] During the combustion of pulverized coal, Na, NaOH, NaCl, Na2O, etc. are released from the coal and condense on the pipe wall, and react with the main elements silicon and aluminum compounds in the ash deposited on the pipe wall at 900-1200°C to form silicon-alumina Sodium acid (sodium feldspar), etc., and all melt at 1300 ° C. Albite itself has a low melting point (1100°C), and it can also dissolve high melting point substances such as quartz and mullite, which will form a large area of molten slagging area in the furnace, thereby forming slagging. During the combustion of pulverized coal, Na2O condensed on the heating surface reacts with SO3 in the flue gas to form Na2SO4. Because Na2SO4 has a low melting point (884°C), it is very easy to adhere to the fine ash in the flue gas to form a fouling layer. Alkaline earth metals (CaO / MgO / Fe2O3) and SO3 in flue ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com