Quick-change shell pulling hook shaft limiting protection structure

A technology of limit protection and shell hook, which is applied in the field of firearms, can solve the problems of large structural size of the machine head, escape of the shell hook shaft, and large opening and closing resistance, so as to improve mobility, good maintainability, and easy replacement and the effect of disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The working principle and structure of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

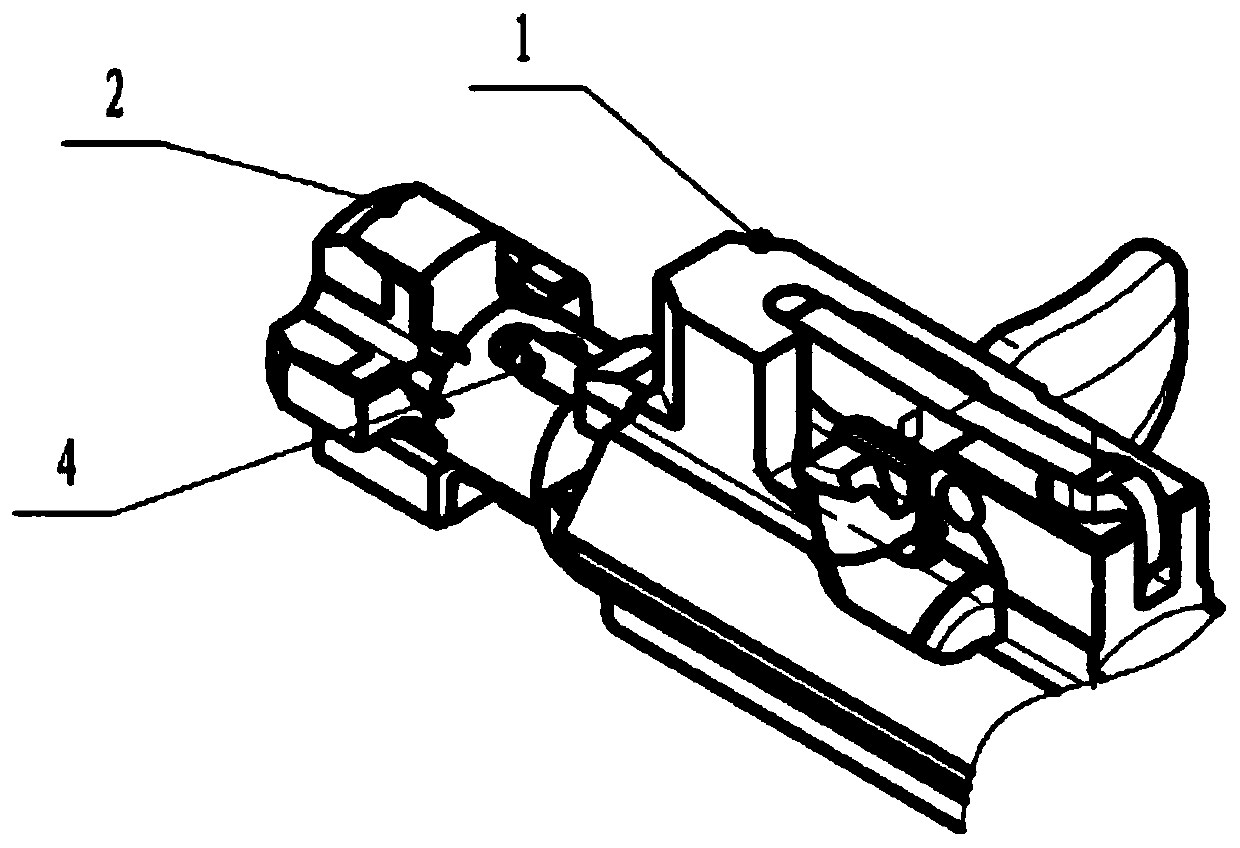

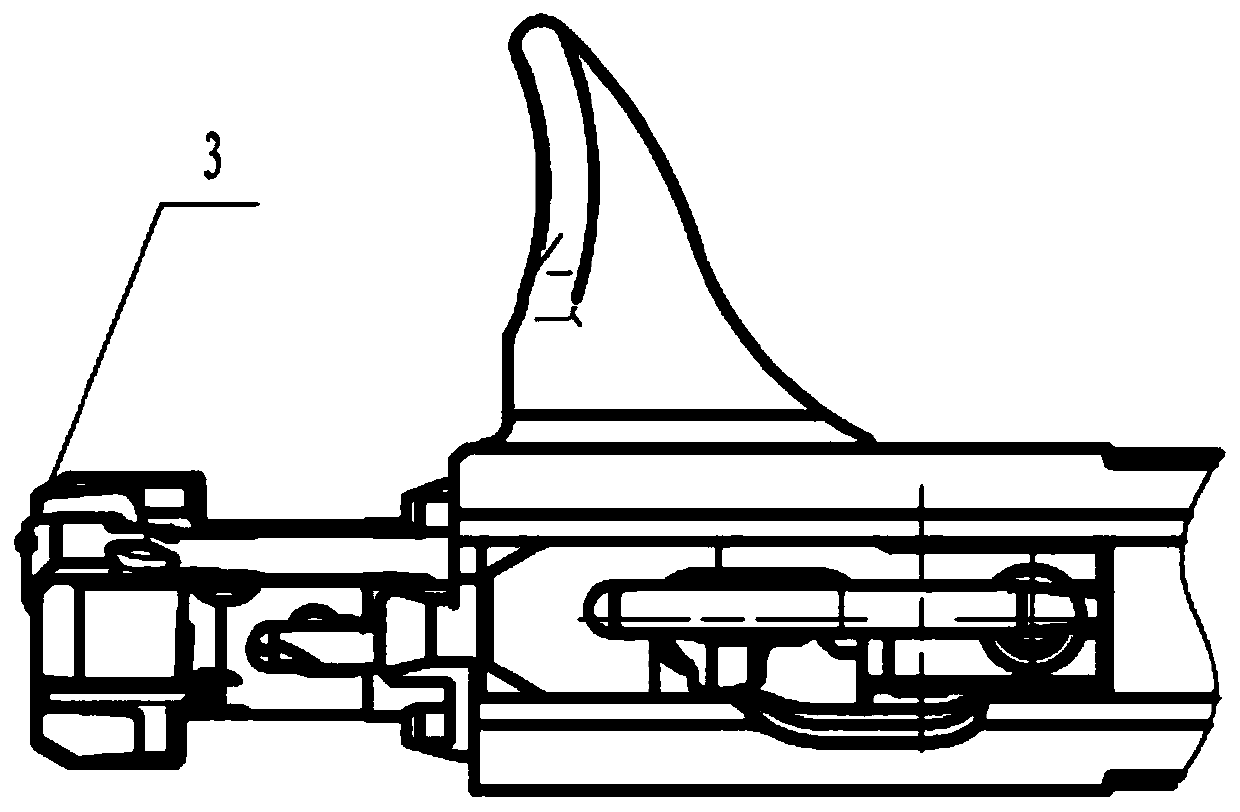

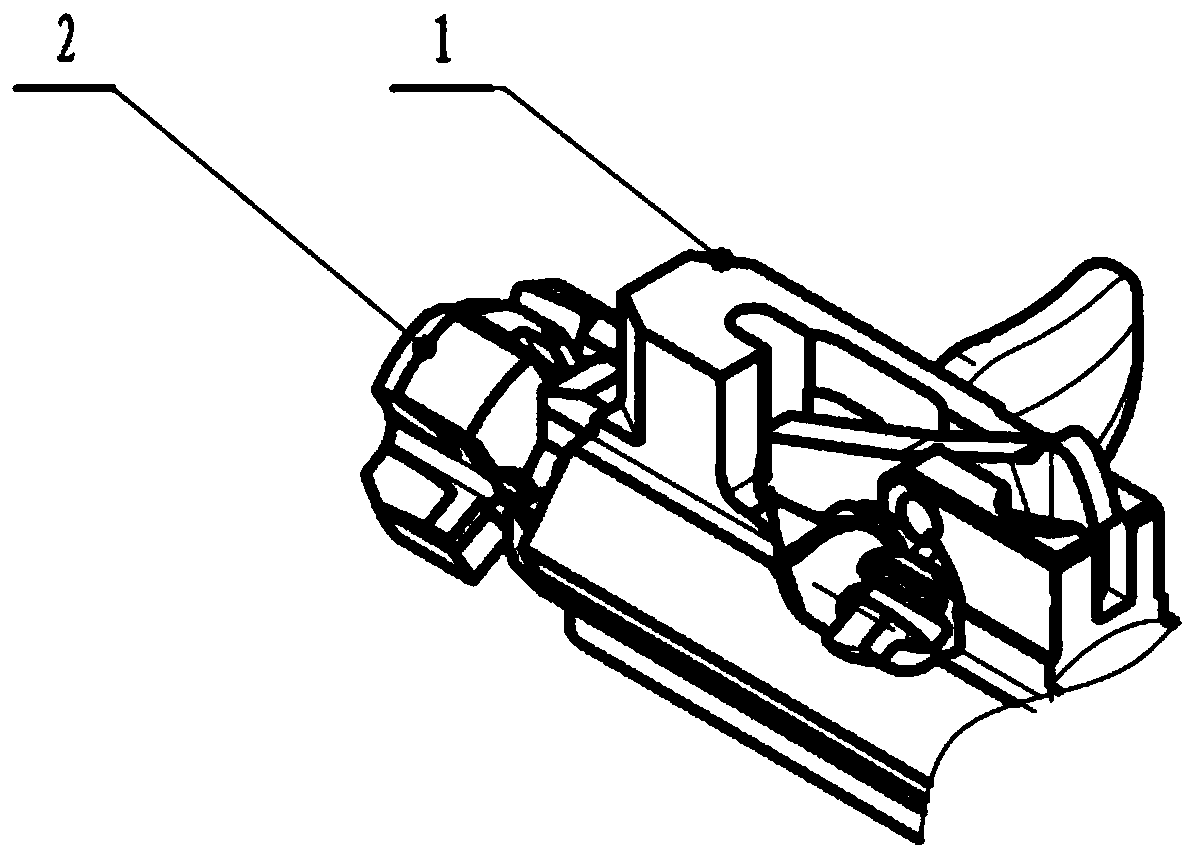

[0029] like Figure 1 to Figure 8 As shown, it is a quick-change shell hook shaft limit protection structure for a certain type of firearm, including a machine frame body 1, a machine head body 2 socketed in the machine frame body 1, and a puller connected to the machine head body 2. The shell hook 3 in the shell hook groove and the shell hook shaft 4 installed on the machine head body 2, the front end of the machine frame body 1 is provided with a protruding shoot 101 in the axial direction, and the protruding shoot 101 is unlocked when the bolt is unlocked. In the state, it is located directly behind the locking teeth of the machine head body, and is used to compress the shell hook shaft 4. The shell hook shaft 4 includes a rod portion 404 and a head portion 401. The front end of the rod portion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com