Automatic stacking device for tunnel kiln

An automatic stacking and tunnel kiln technology, which is applied to the braking device, hoisting device, transportation and packaging of lifting equipment, etc., can solve the problems of low degree of automation and work efficiency, high labor intensity, low stacking efficiency, etc. Achieve the effect of improving work efficiency, reducing labor intensity and maintaining good maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

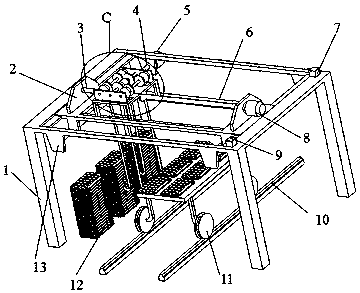

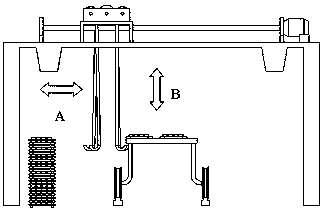

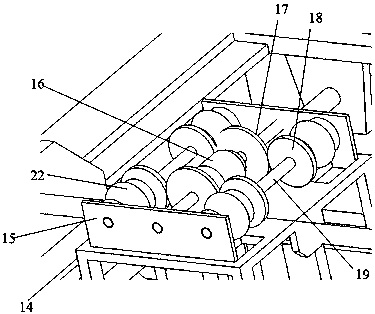

[0015] control Figure 1 to Figure 4 , The kiln car 11 moves along the grounding guide rail 10 to directly below the main support 1, and the main motor 5 drives the sliding plate 6 to move in the direction where the kiln car 11 enters the main support 1 through the large screw rod 4 until it touches the front travel switch 9 At the same time, the small motor 8 drives the sliding frame 14 to move to the limit position to the left through the small screw rod 3, and the lifting motor 16 makes the hook 12 move upward to the highest position, and then the staff needs to transport the bowl billet stacking unit to The left side of the kiln car 11 and just below the main support 1, the device has completed the preparatory work this moment.

[0016] After the equipment is started, the small motor 8 drives the sliding frame 14 to the right through the small screw rod 3 to move to the right above the bowl billet stacking unit, and then the lifting motor 16 drives the rotation of the pini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com