Characterization method of polymer gel point based on complex wave constant rate temperature sweep rheology

A polymer and composite wave technology, applied in the field of polymer gel rheology characterization, can solve the problems of difficult to obtain gel point data and easy change of gel structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

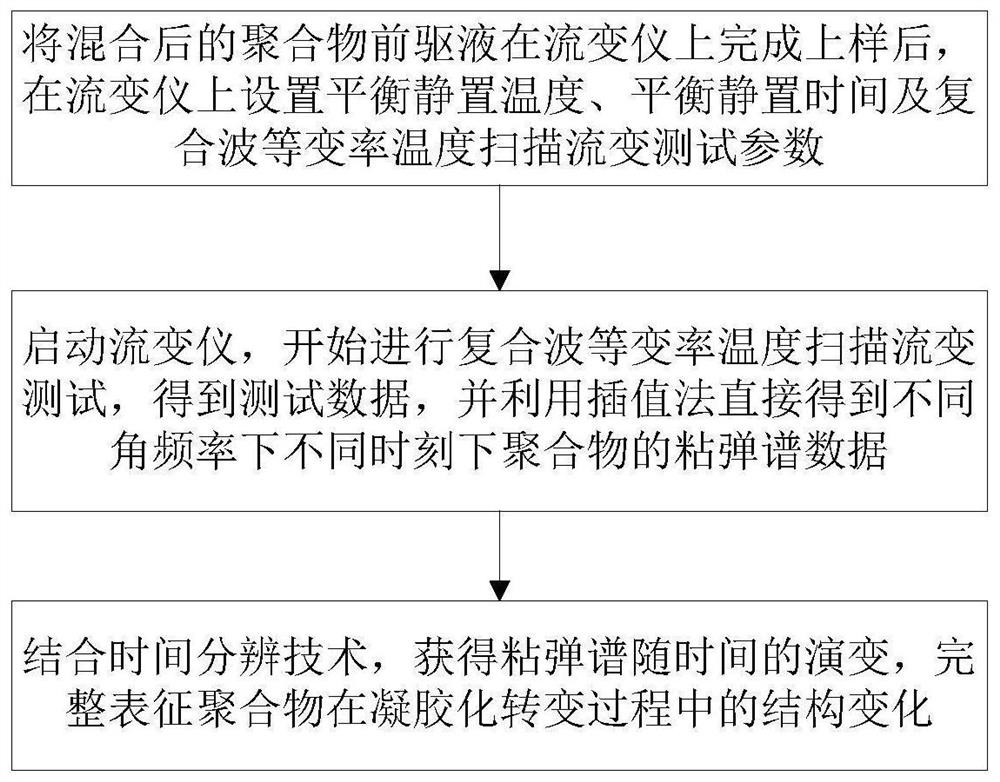

Method used

Image

Examples

preparation example Construction

[0033] (1) Preparation of aqueous gelatin solution:

[0034] Add the gelatin to a wide-mouthed glass bottle with a lid and a magnetic stirrer filled with ultrapure water with a conductivity equal to 18.2MΩ·cm, let it stand in a water bath at 60°C for 20 minutes, and stir vigorously (400-800rpm, 1h), finally dissolving the gelatin to form a clear and transparent liquid to obtain a mixed gelatin aqueous solution, wherein the mass fraction of gelatin is 6 wt%.

[0035] (2) Characterize the microstructure and viscoelasticity of the mixed gelatin aqueous solution sample under oscillating shear conditions, that is, the multiwave rheological test.

[0036] After installing the upper and lower fixtures of the coaxial cylinder on the rheometer, the automatic clearance is reset to zero, the upper fixture is raised, the gelatin aqueous solution sample is loaded into the lower fixture of the coaxial cylinder, and the fixture gap is automatically adjusted to the test gap. Loading complete...

Embodiment 1

[0043]The gel point characterization method of 6wt% gelatin based on the mass fraction of complex wave constant rate temperature scanning rheological test, the specific steps are as follows:

[0044] (1) Accurately and quickly weigh 6.3830g of dry gelatin, add it to a jar equipped with a stirring bar, measure 100mL ultrapure water with a graduated cylinder, add it to the jar, tighten the bottle cap, and place it in a water bath at 60°C After standing still for 20 minutes, stir at a stirring speed of 500 rpm for 1 hour to obtain a transparent and clear solution as a sample;

[0045] (2) Carry out the composite wave constant rate temperature scanning test on the sample. The test parameters of the complex wave constant rate temperature scanning test are: the equilibrium temperature is 60°C, the equilibrium time is 300s; the initial temperature is set to 60°C, and the temperature scanning rate is The temperature is 5°C / min, the end temperature is 28°C, the holding time at the end ...

Embodiment 2

[0049] The gel point characterization method of 6wt% gelatin based on the mass fraction of complex wave constant rate temperature scanning rheology test, the specific steps are as follows:

[0050] (1) Accurately and quickly weigh 6.3830g of dry gelatin, add it to a jar equipped with a stirring bar, measure 100mL ultrapure water with a graduated cylinder, add it to the jar, tighten the bottle cap, and place it in a water bath at 60°C After standing still for 20 minutes, stir at a stirring speed of 500 rpm for 1 hour to obtain a transparent and clear solution as a sample;

[0051] (2) Carry out the composite wave constant rate temperature scanning test on the sample. The test parameters of the complex wave constant rate temperature scanning test are: the equilibrium temperature is 60°C, the equilibrium time is 300s; the initial temperature is set to 60°C, and the temperature scanning rate is The temperature is 5°C / min, the end temperature is 29.4°C, the holding time at the end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| loss modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com