Spraying structure for fish pond culture spraying feeding device

A fish pond and spray head technology, applied in application, fish farming, climate change adaptation, etc., can solve the problems of inability to guarantee, consume a lot of time, and block the connecting pipe, so as to avoid feed backspray, improve the effect, and avoid The effect of pipe blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

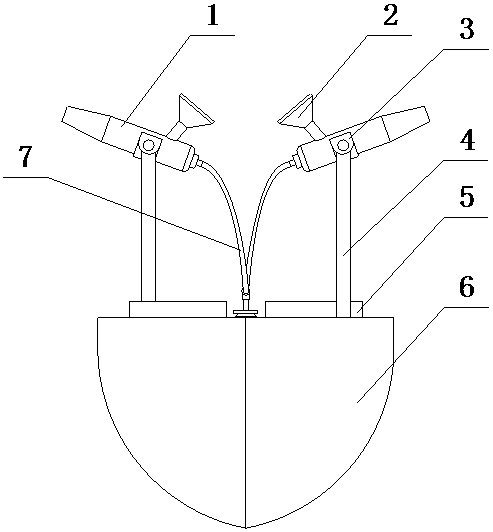

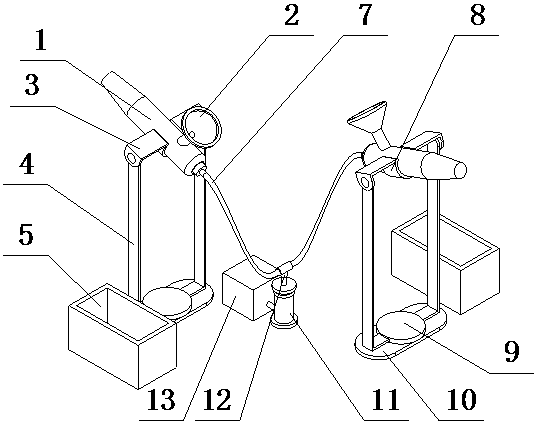

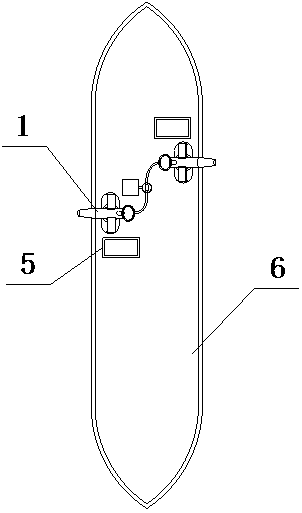

[0023] A spraying structure for a fish pond breeding spray feeding device of the present invention is realized in the following way: a spraying structure for a fish pond breeding spray feeding device of the present invention consists of a spray head (1), a feeding hopper (2), a driving motor (15 ), connecting pipe (16), deflector (17), conveying pipe (18), spiral blade (19), guide frame (20), limit cap (21), bearing (22), top ball block (23 ), a dredging plate (24) and a sliding rod (25), one end of the conveying pipe (18) is connected to the spray head (1) and communicated with each other, and the other end of the conveying pipe (18) first extends obliquely upward to form The inclined pipe is bent horizontally and extended for a certain distance to form a straight pipe. One end of the connecting pipe (16) is connected to the conveying pipe (18) and communicated. The connecting pipe (16) is close to the other end of the conveying pipe (18) , the feeding hopper (2) is placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com