Automatic injection device

A technology of automatic injection and injection components, which is applied in the field of medical appliances, can solve problems such as rupture, high failure rate, and many parts involved, and achieve the effects of improving reliability and safety, ensuring medical effects, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

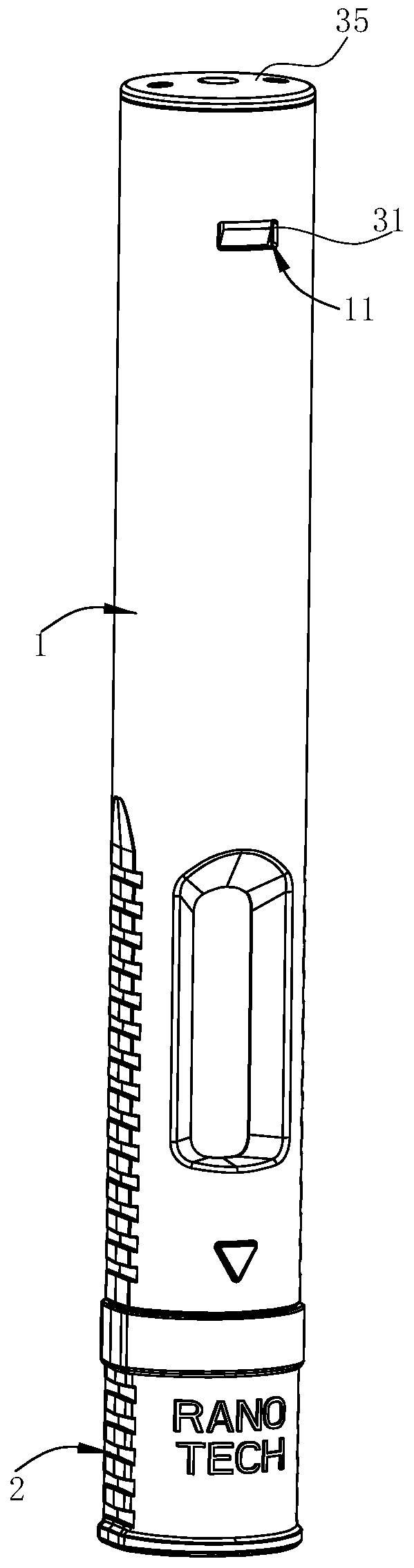

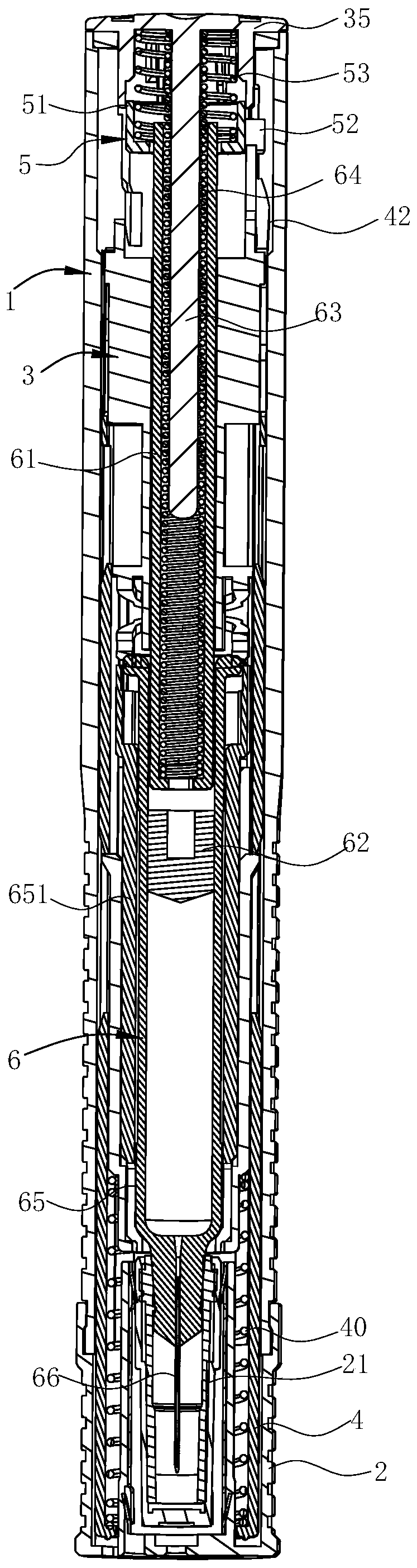

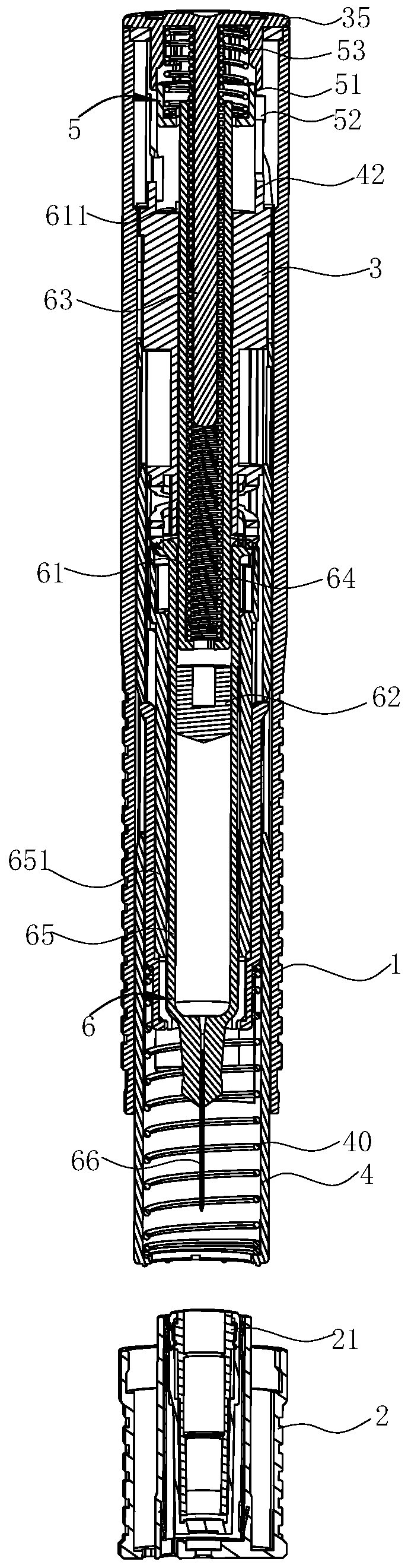

[0049] Such as Figure 1-22 As shown, the automatic injection device of this preferred embodiment includes a tube body 1, a cap body 2, a fixed sleeve 3, a movable sleeve 4, a sounding part 5 and an injection assembly 6, the lower end of the tube body 1 is open, and the cap body 2 is covered on the The lower end of the tube body 1 is in the shape of a pen holder, which is small in size and easy to use.

[0050] Such as figure 2 , 3 , 4, the movable sleeve 4 is arranged in the tubular body 1, and the lower end of the movable sleeve 4 can extend out of the tubular body 1 and move upward relative to the tubular body 1 when pressed by the skin. The downward trend is always maintained.

[0051] The movable sleeve 4 is set on the fixed sleeve 3, and the fixed sleeve 3 is positioned relative to the pipe body 1. The side wall of the movable sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com