Efficient filtering equipment for sewage treatment

A technology of sewage treatment and filtration equipment, applied in the direction of filtration separation, fixed filter element filter, separation method, etc., can solve the problems of low overall efficiency of sewage treatment, untimely manual cleaning, and waste of manpower and material resources, etc., to achieve improvement Sewage treatment efficiency, timely and efficient cleaning, and the effect of promoting the falling of debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

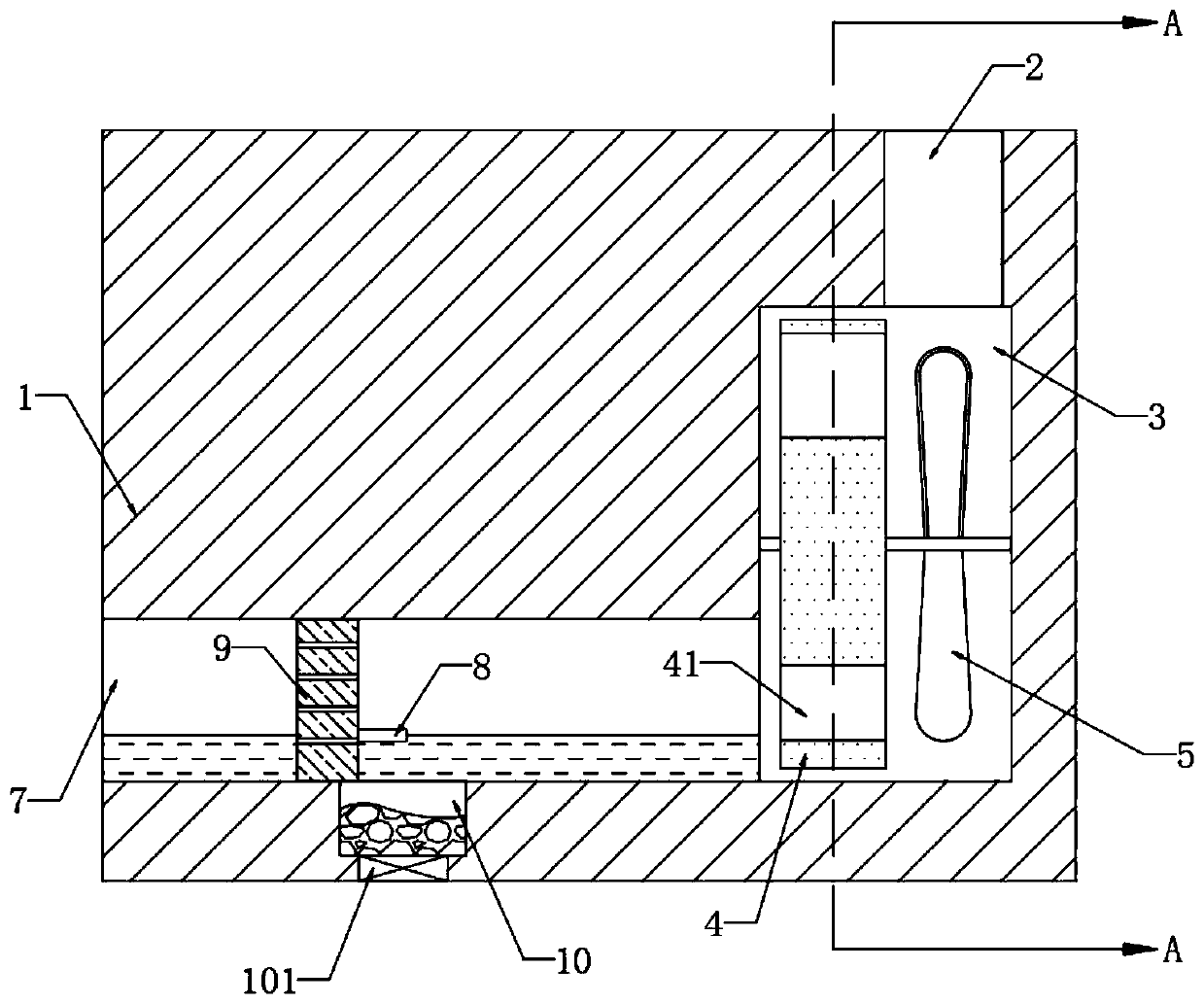

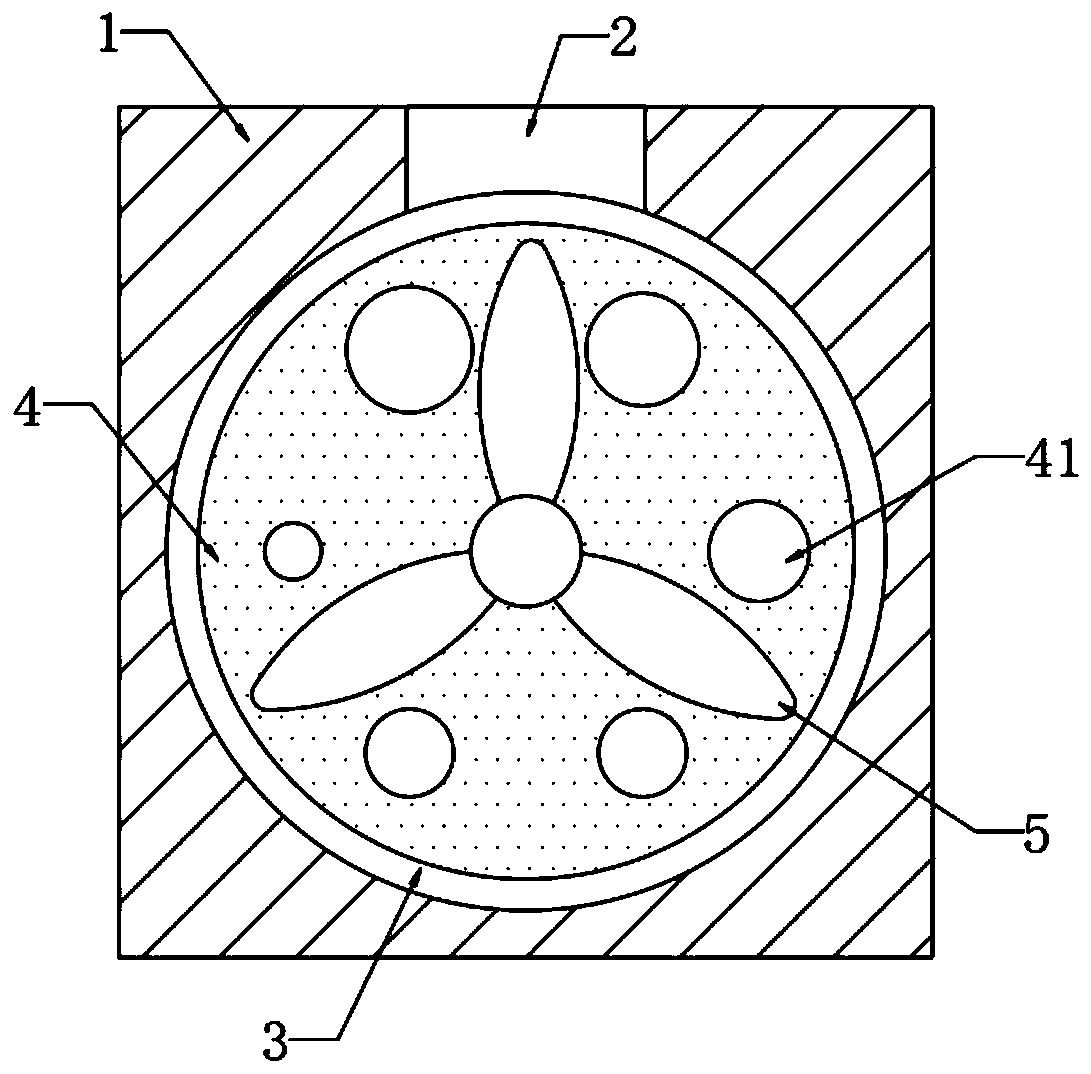

[0023] refer to Figure 1-2 , a high-efficiency sewage treatment filter equipment, including equipment base 1, the upper end of the equipment base 1 is provided with a water inlet 2, the side wall of the equipment base 1 is provided with a circular groove 3 communicating with the water inlet 2, the circular groove 3 The inner coaxial seal is rotatably connected with a turntable 4 , the side wall of the turntable 4 is provided with a plurality of through holes 41 of different sizes, and the side wall of the turntable 4 is coaxially fixedly connected with a water wheel 5 . A water outlet 7 communicating with the inside of the circular groove 3 is opened on the side wall of the equipment base 1 .

[0024] It should be noted that the blades of the water wheel 5 and the through hole 41 are arranged in a misaligned position, so as to prevent the blades of the water wheel 5 from blocking the through hole 41 and obstructing the flow of sewage. The calibers of the water inlet 2 and th...

Embodiment 2

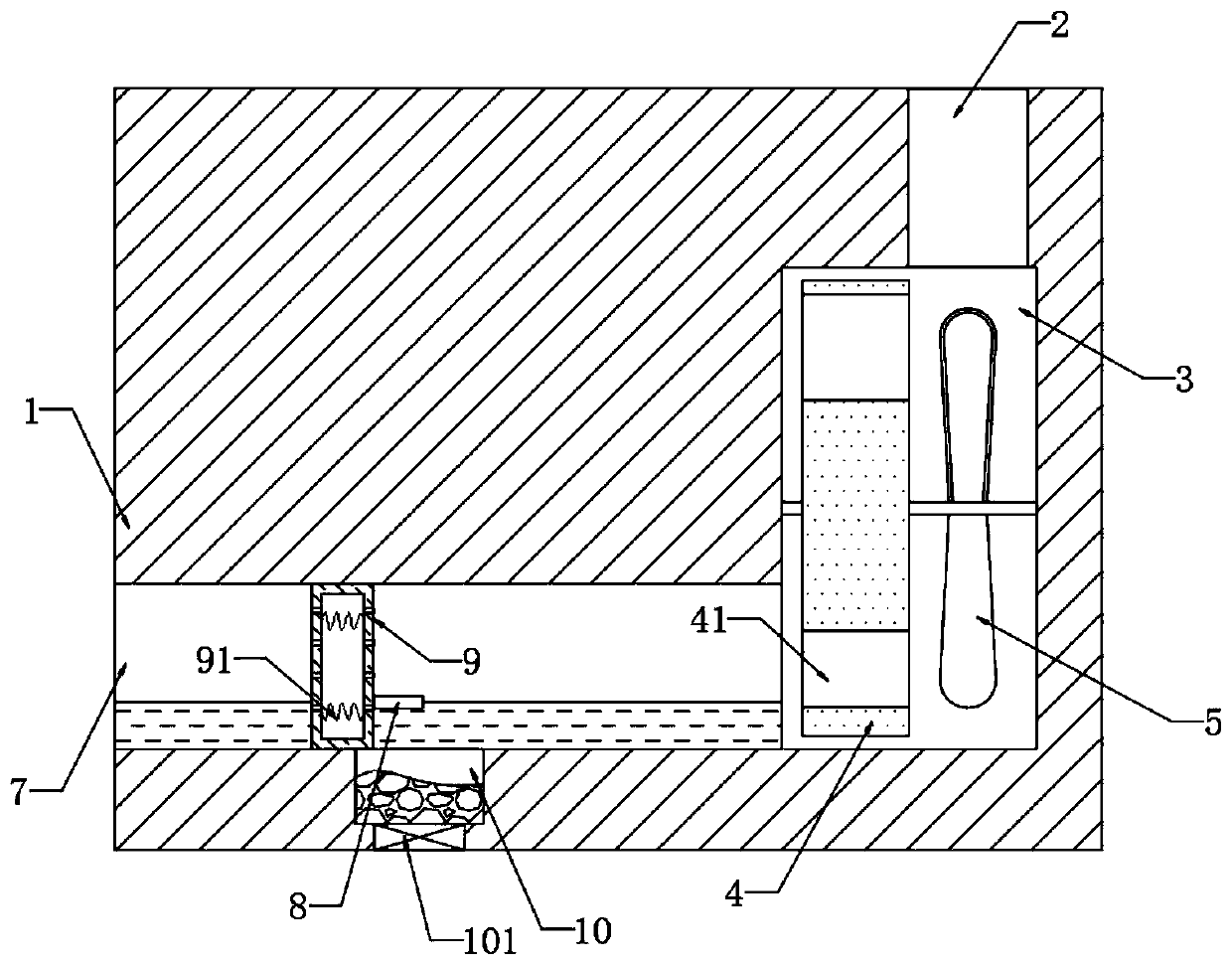

[0032] refer to image 3 , and the difference from the first embodiment is that the buoyancy scraper 8 is made of magnetic material, the filter screen 9 is made of a hollow structure, and the filter screen 9 is embedded with a plurality of iron springs 91 .

[0033] In this embodiment, since the buoyant scraper 8 is made of magnets and the springs 91 are made of iron, the buoyant scraper 8 will be close to each spring 91 in the filter screen 9 during the process of floating up and down.

[0034] Whenever the magnetic buoyancy scraper 8 approaches a certain spring 91, the spring 91 will shrink along the direction of the buoyancy scraper 8, and when the buoyancy scraper 8 leaves, the spring 91 will elongate and recover under the action of the elastic force. In this way, during the up-and-down floating process of the buoyancy scraper 8, the springs 91 in the filter screen 9 are stretched one by one, and the outer wall of the filter screen 9 is continuously shaken, which can promo...

Embodiment 3

[0036] refer to Figure 4-5 , and the difference from the second embodiment is that the side wall of the device base 1 is provided with an air inlet 6 communicating with the water outlet 7, and the air inlet 6 communicates with the inside of the filter screen 9. Such as Figure 4 As shown, the air inlet 6 communicates with the water outlet 7 , and the air outlet end of the air inlet 6 is arranged inside the hollow filter screen 9 .

[0037] In this embodiment, when the sewage flows in the water outlet 7, because the water flow velocity in the water outlet 7 is fast and the pressure is low, the air flow velocity in the air inlet 6 connected with the water outlet 7 is slow and the pressure is strong, so that the water flow in the air inlet A pressure difference is generated in the hole 6, and the air is continuously sucked in from the air inlet hole 6, and the air flowing in from the air inlet hole 6 will enter the filter screen 9 and be discharged from the filter hole of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com