Polymer microporous membrane and preparation method thereof, and water treatment equipment

A polymer and microporous membrane technology, applied in water/sewage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve problems such as pollution, membrane fouling, etc., to avoid peeling, good Effect, effect of solving membrane fouling and temperature polarization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] An embodiment of the present invention also provides a method for preparing the polymer microporous membrane, comprising:

[0048] Applying a hydrophilic modification liquid on the hydrophobic base film, so that the hydrophilic modification liquid is immersed in the hydrophobic base film, and the hydrophilic modification liquid has an initiator, a modified monomer and a solvent ;as well as

[0049] Transfer the hydrophobic base membrane immersed in the hydrophilic modification solution to hot water at 40° C. to 80° C., stay for 3 hours to 18 hours, and then take it out to dry.

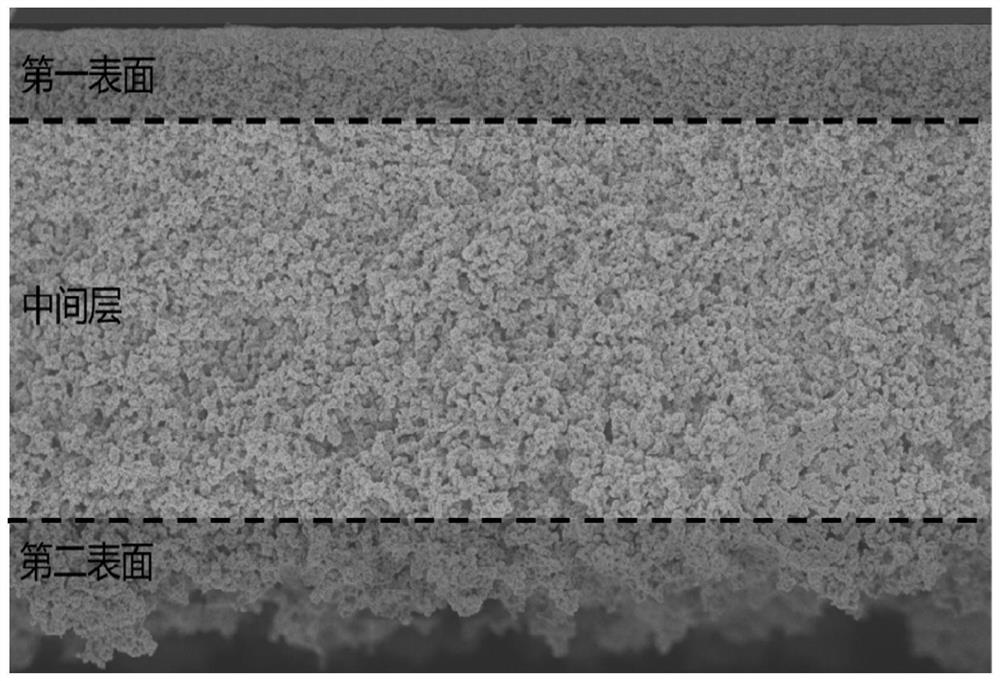

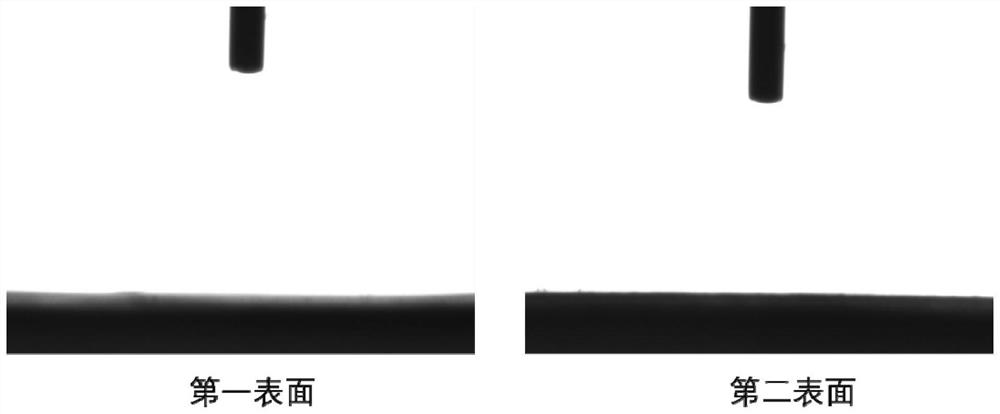

[0050] In this embodiment, it is proposed to fix the hydrophilic modification liquid on the surface of the hydrophobic base film by micro-swelling / cross-linking at the interface. In this process, when the hydrophilic modification liquid is applied on the hydrophobic base film, the hydrophilic modification liquid is The hydrophobic base film penetrates into the hydrophobic base film from the out...

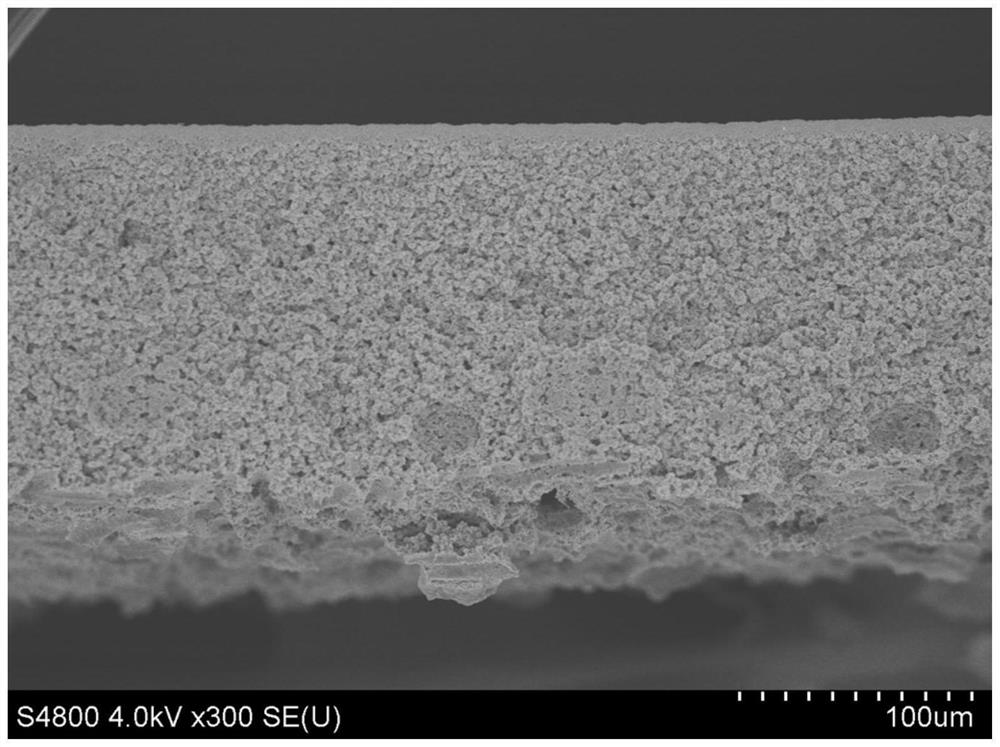

Embodiment 1

[0070] (1) Dissolve 15g of polyvinylidene fluoride in 85g of triethyl phosphate, stir at 60°C for 12h, prepare a film-forming precursor solution, and perform vacuum defoaming treatment on the prepared precursor solution to obtain a clear and transparent solution Using a scraper with a thickness of 200 μm, the casting liquid was uniformly scraped on the non-woven fabric to obtain a primary film, and then the primary film was quickly transferred to a coagulation bath with a volume fraction of 60% triethyl phosphate. , stay in the coagulation bath for 10s for curing, transfer the cured film to deionized water, soak for 24h, take out the film to dry, and peel off the non-woven fabric to obtain a polyvinylidene fluoride hydrophobic base film.

[0071] (2) Under nitrogen or argon atmosphere, mix 0.6g of azobisisobutyronitrile, 40g of N-vinylpyrrolidone, 30g of vinyltriethoxysilane, and 30g of triethyl phosphate, and then add 300g of triethyl phosphate. The polymerization reaction wa...

Embodiment 2

[0075](1) Dissolve 18g of polyvinylidene fluoride in 72g of dimethylacetamide, stir at 80°C for 12h, prepare a film-forming precursor solution, and perform vacuum defoaming treatment on the prepared precursor solution to obtain a clear Transparent casting solution, with a scraper with a thickness of 100 μm, the casting solution was uniformly scraped on the non-woven fabric to obtain a primary film, and then the primary film was rapidly transferred to a volume fraction of 40% dimethylacetamide for solidification In the bath, stay in the coagulation bath for 20 hours for curing, transfer the cured film to deionized water, soak for 48 hours, take out the film to dry, and peel off the non-woven fabric to obtain a polyvinylidene fluoride hydrophobic base film.

[0076] (2) Under nitrogen or argon atmosphere, 0.8g azobisisobutyronitrile, 45g N-vinylpyrrolidone, 28g vinyltriethoxysilane, and 40g dimethylacetamide were mixed uniformly, and then 350g dimethylacetamide was added. The po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com