Punching machine for environment-friendly lavatory shell

A technology for toilets and shells, which is applied in the field of punching machines for the processing of environmentally friendly toilet shells, can solve the problems of low stamping work efficiency and operator injury, and achieve the effects of ensuring work efficiency, reasonable structural design, and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

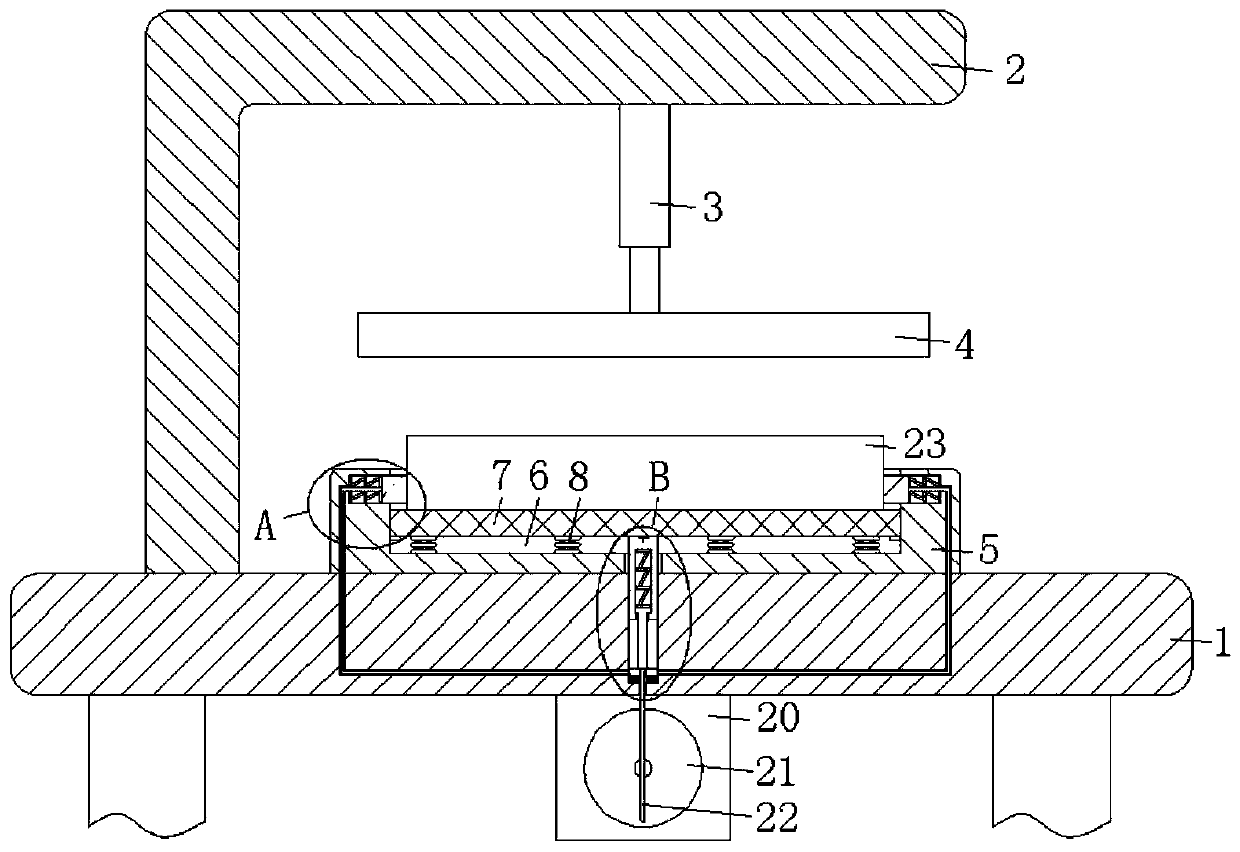

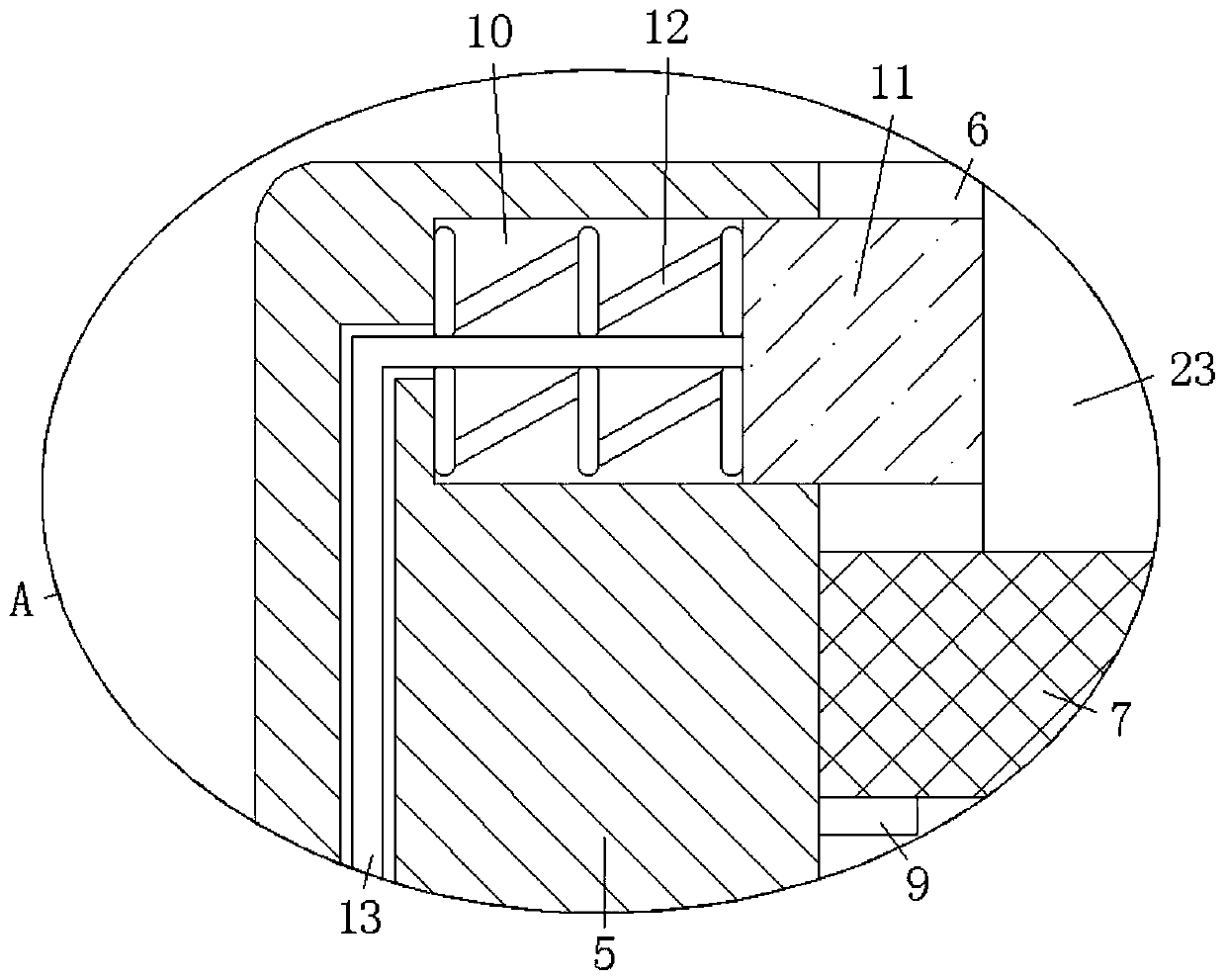

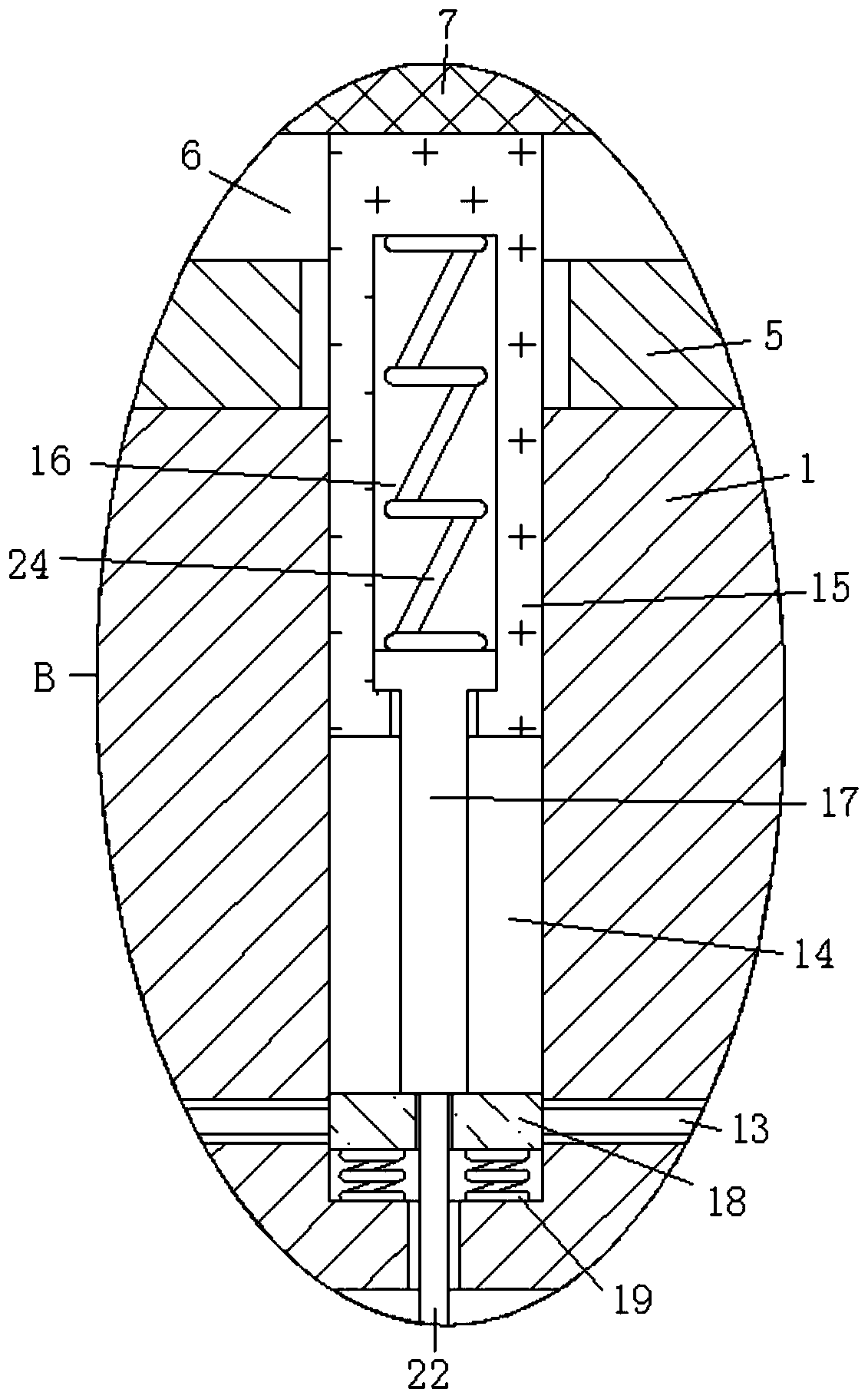

[0020] refer to Figure 1-3 , a punching machine for environmental protection toilet shell processing, comprising a workbench 1, a workpiece 23 to be processed, a plurality of support legs are fixedly connected to the bottom of the workbench 1, a punching mechanism is fixedly connected to the upper end of the workbench 1, and the punching mechanism includes a punching mechanism fixedly connected to The L-shaped plate 2 at the upper end of the workbench 1, the bottom of the L-shaped plate 2 is fixedly connected with the electric telescopic rod 3, and the telescopic end of the electric telescopic rod 3 is fixedly connected with the upper mold 4. It should be noted that the electric telescopic rod 3 can drive The upper die 4 moves downward to carry out stamping work;

[0021] The upper end of the workbench 1 is fixedly connected with a mounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com