Staggered mounting method of lower furnace shell and in-furnace equipment of air heating furnace

An installation method and technology of hot blast stoves, which are applied to blast furnace parts, metal processing equipment, furnaces, etc., can solve the problems of shortened construction period and long construction period, and achieve the effects of shortened construction period, convenience and accuracy, and guaranteed installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

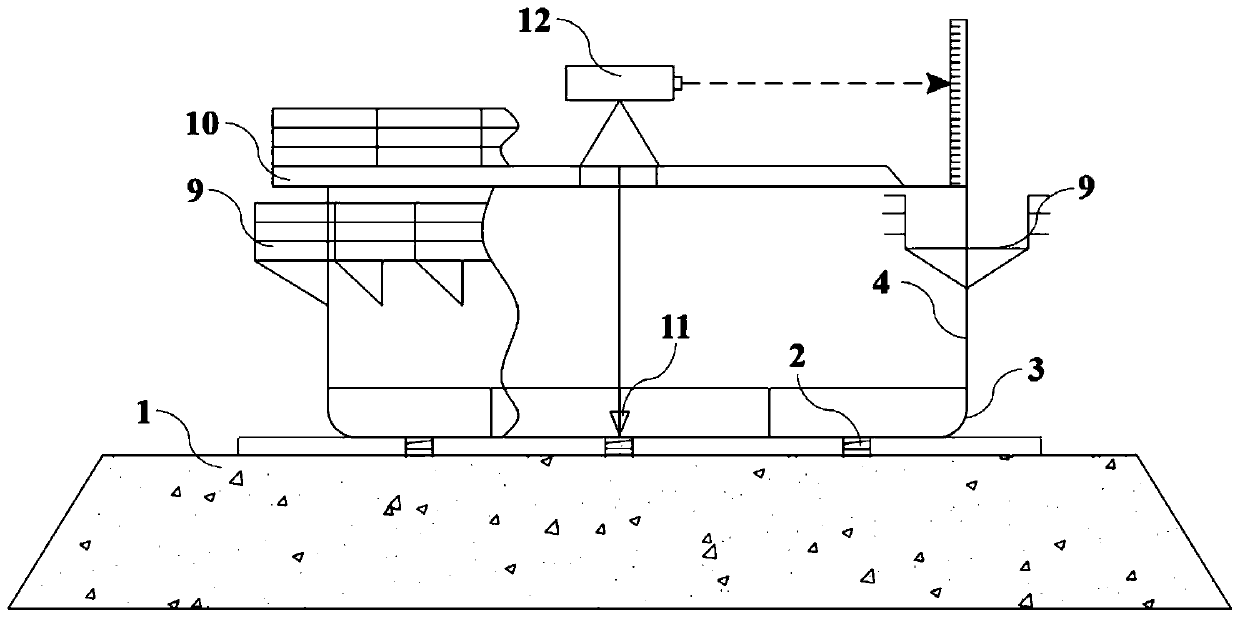

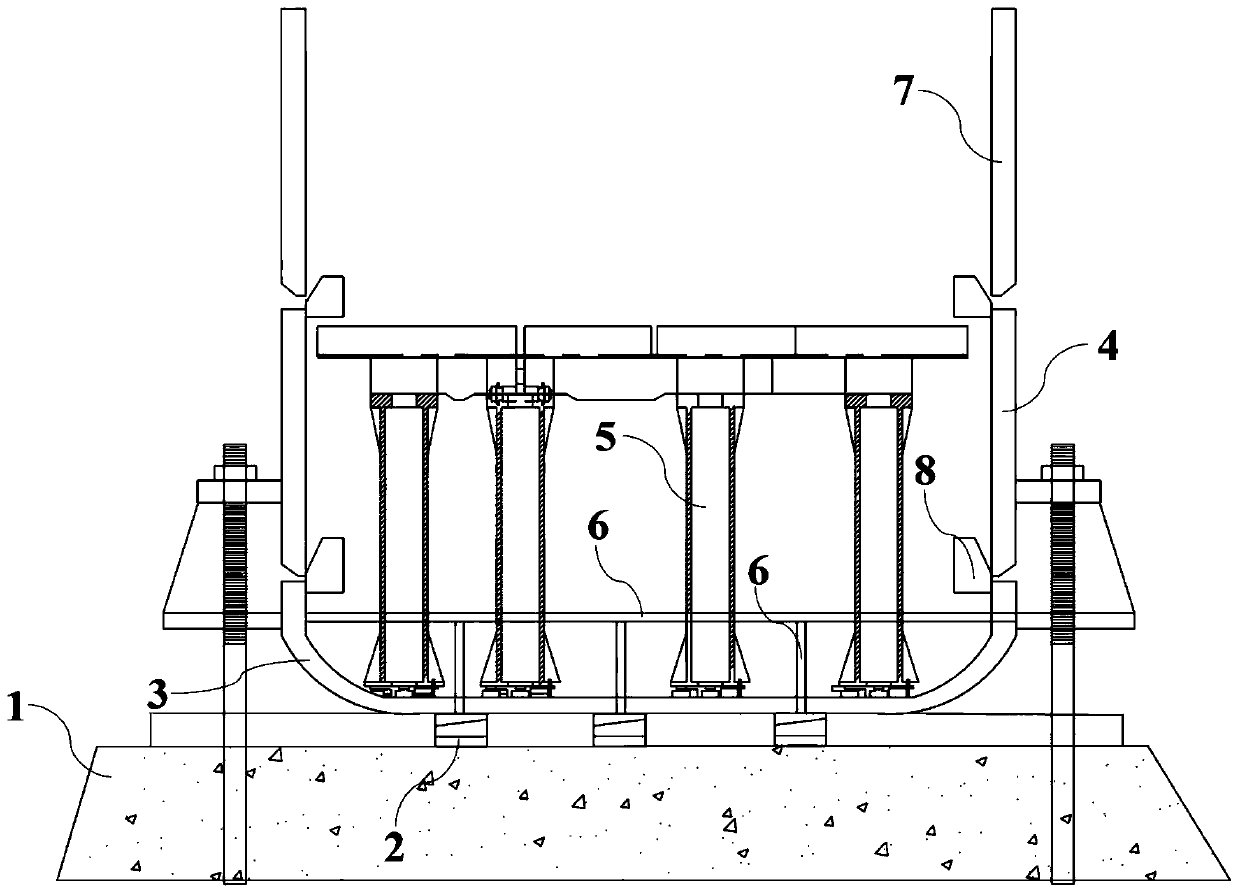

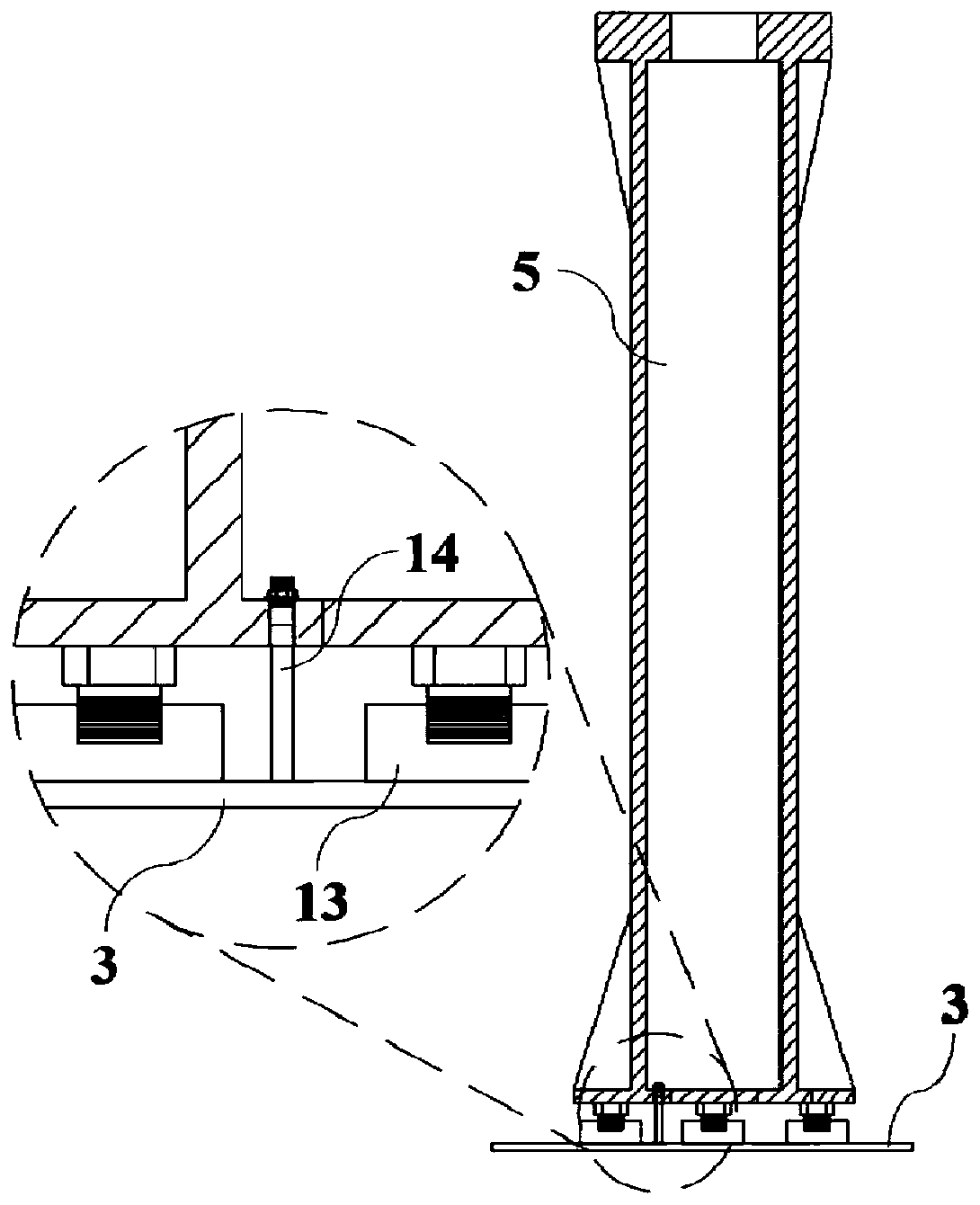

[0036] In the prior art, during the installation process of the lower part of the hot blast stove as a whole, in order to ensure the accuracy of the installation of various equipment inside the furnace shell, after the furnace shell of the hot blast stove is fixed and installed in advance, the various devices inside the furnace shell are installed. After the installation of the furnace shell is completed, the furnace shell is a whole, and its position will not change. Therefore, it is convenient for the operator to find the installation reference point when installing each device, so as to ensure the accuracy of the installation. However, due to the installation of the furnace shell After completion, the construction work area is limited and difficult to operate, resulting in a longer construction period.

[0037] In order to solve the above problems, a method for staggered installation of the lower furnace shell of the hot blast stove and the equipment in the furnace according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com