Recycling equipment for scrapped automobiles

A technology for recycling equipment and scrapped cars, applied in cleaning methods and appliances, cleaning methods using liquids, metal processing, etc., can solve problems such as unfixable waste tires, tires bouncing off, incomplete crushing, etc., to increase the scope of use , Increase stability, avoid cutting irregular effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

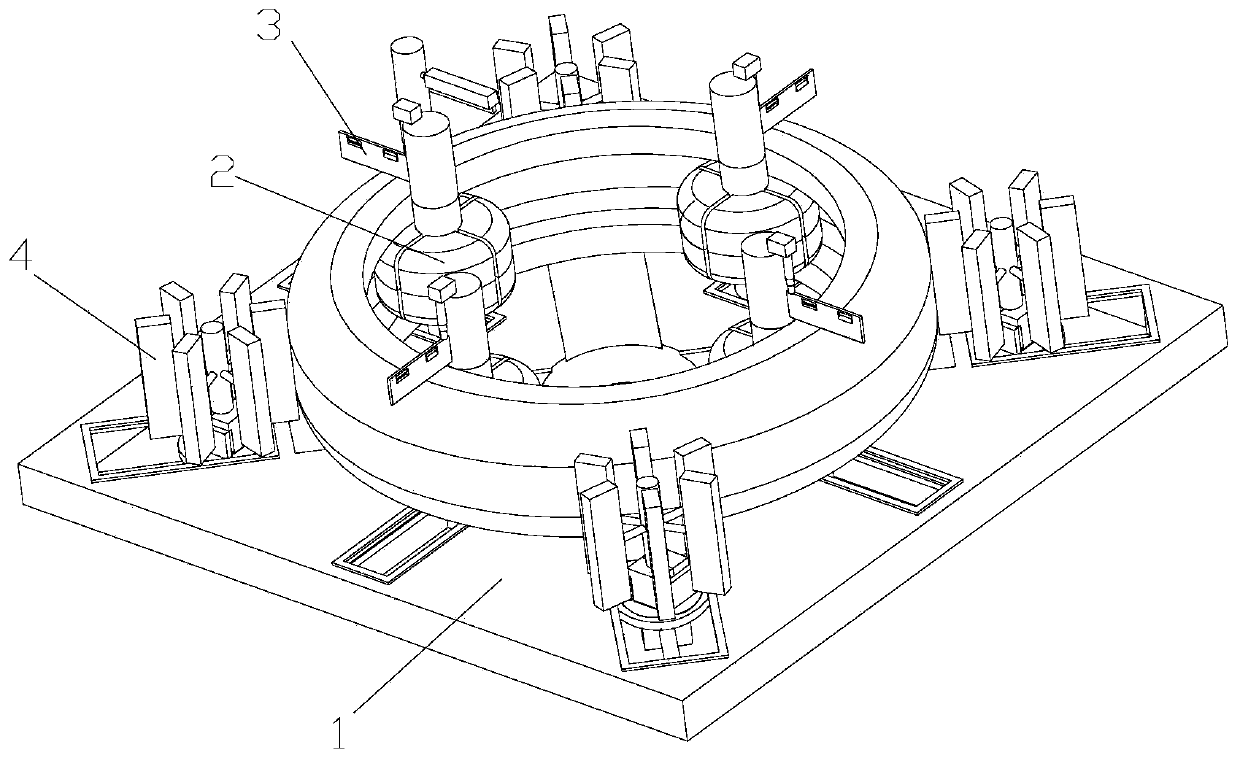

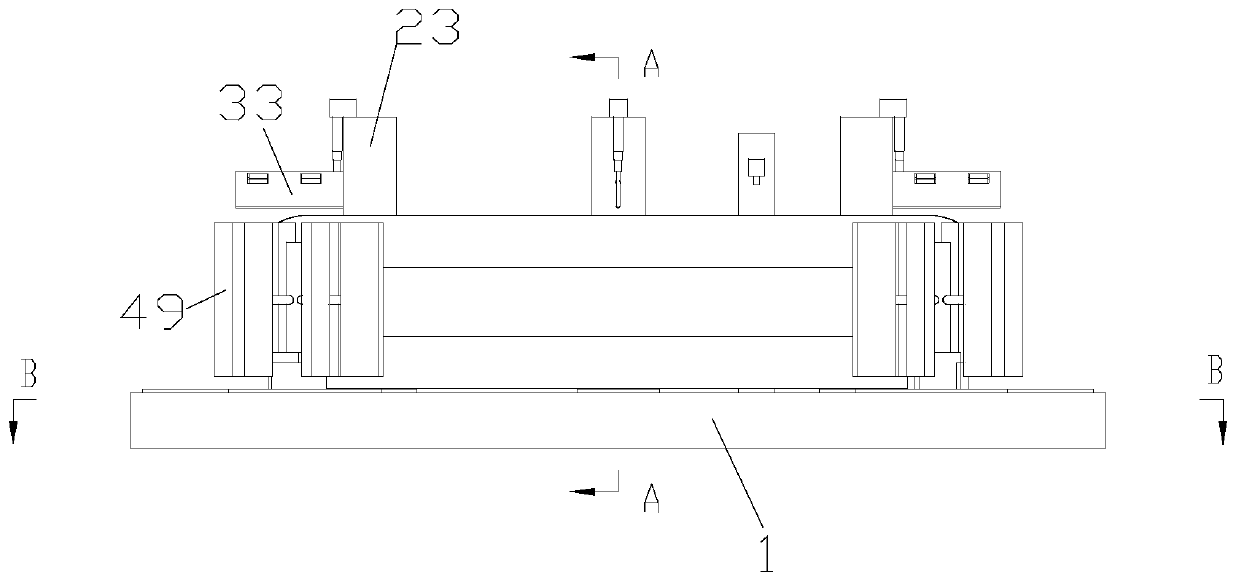

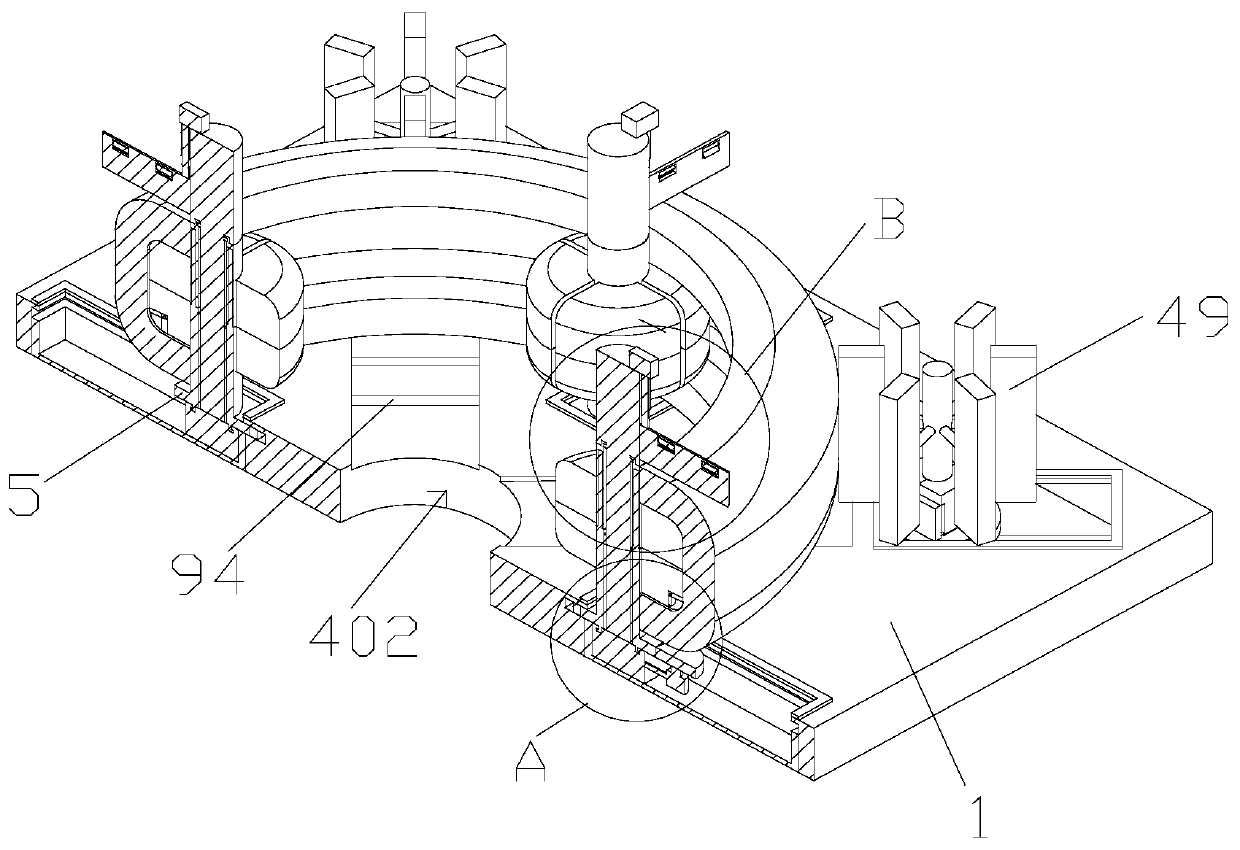

[0027] Such as Figure 1-6 As shown, a kind of recycling equipment for scrapped automobiles includes a workbench 1, a plurality of fixing devices 2 arranged on the workbench, a plurality of cutting devices 3 respectively arranged on a plurality of fixing devices, a cleaning machine arranged on the workbench The device 4, the transmission device 5 for connecting the cleaning device and the plurality of fixing devices.

[0028] The fixing device 2 includes a track 21, a slider 22, a fixed rod 23, a first fixed block 24, a second fixed block 25, a first telescopic rod 26, a limit rod 27, a limit groove 28, a roller 91, and a rotating wheel 92, a plurality of top blocks 93; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com