End cover part with spiral groove, and numerically-controlled machining method thereof adopting five-axis linkage machine tool

A five-axis linkage machine tool and processing method technology, which is applied to engine components, engine seals, mechanical equipment, etc., can solve the problems of inconvenient use, time-consuming and laborious disassembly, etc., to ensure the sealing effect, the sealing performance, and the product production conditions. universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

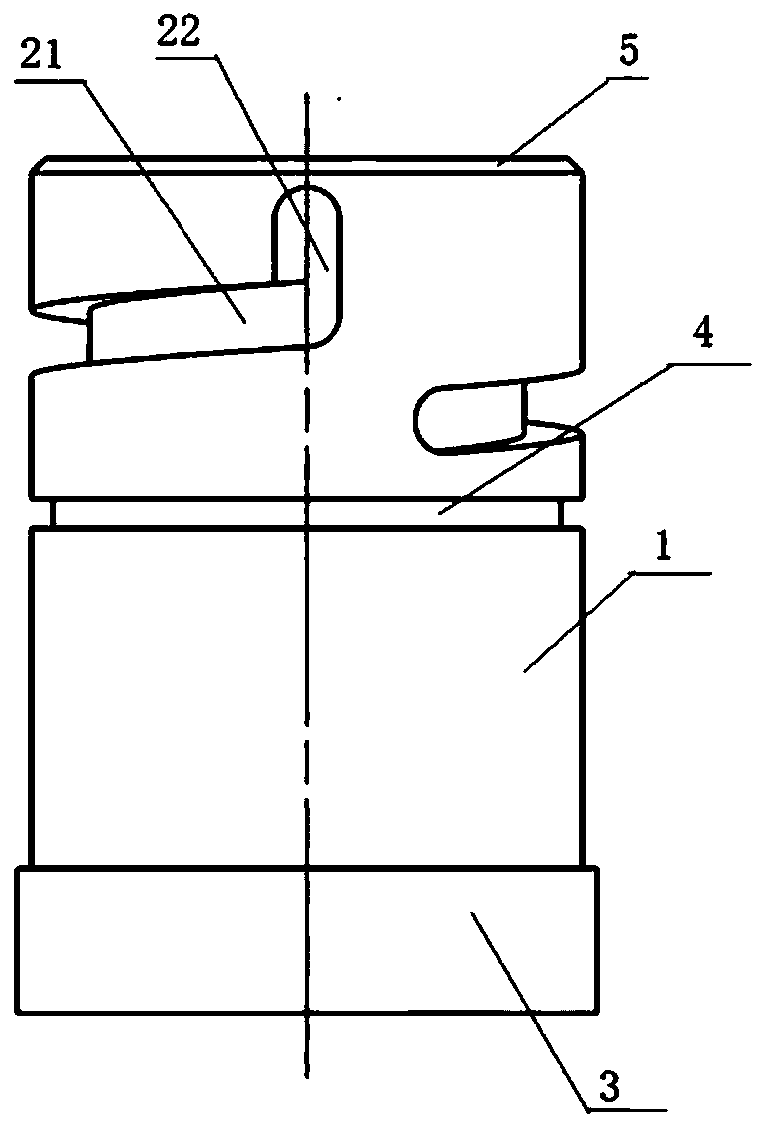

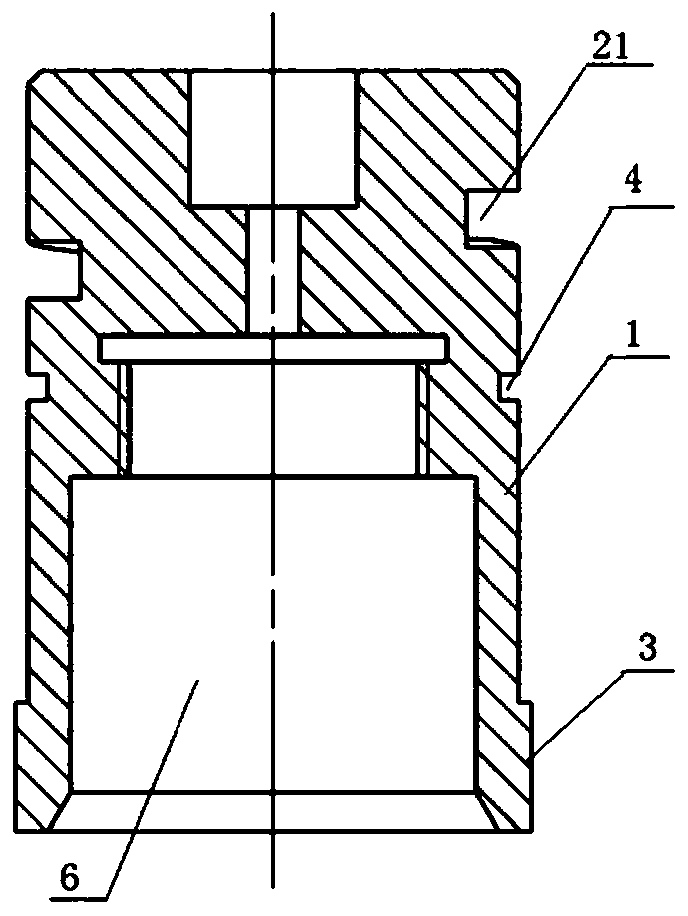

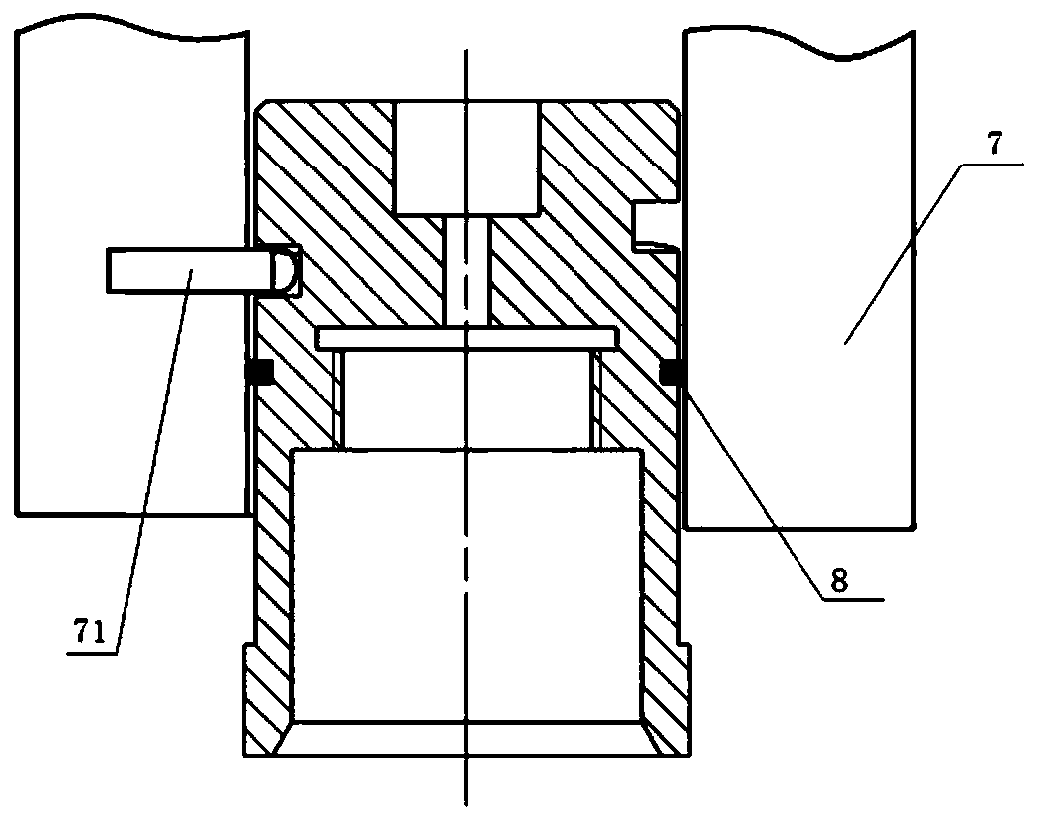

[0039] An end cap part with a helical groove, such as Figure 1~3 As shown, it includes a cylindrical end cap body 1, and the inside of the end cap body 1 has a channel 6 penetrating along the central axis. The first end of the end cap body 1 is provided with a spiral groove type quick connection mechanism for connecting with the The elastic positioning pin 71 in the outlet interface 7 of the storage device is matched and connected, and the second end of the end cover body 1 is used for an external device (in this embodiment, the second end of the end cover body 1 is provided with an expansion head 3 for an external device) . No embodiment Aiming at the defects of the prior art, redesign the connection mode between the outlet interface of the paint storage equipment and the end cap parts, and use the elastic positioning pins arranged in the side wall of the outlet interface of the paint storage equipment and the specially designed screw on the end cap parts. The groove type q...

Embodiment 2

[0042] A five-axis linkage machine tool numerical control machining method for an end cap part with a spiral groove, used for processing the end cap part with a spiral groove in Example 1, comprising the following steps:

[0043] S1: Use a three-jaw chuck to clamp the outer circle of one end of the blank (the embryo is a cylinder with a diameter of 45mm and a length of 60mm), and turn the outer circle, outer circle chamfer and sealing groove. In this embodiment, a three-jaw chuck is used to clamp Hold one end φ42mm outer circle, car outer circle Long, external round chamfer 0.5×45°, turning seal groove

[0044] S2: Use a center drill to drill the center positioning hole on the outer circular end face and then drill the hole to ensure the center position of the hole. In this embodiment, Use a center drill to drill a center hole on the end face of the outer circle, and drill a hole with a depth of φ12×10.5mm on the upper end face;

[0045] S3: On the basis of step S2, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com