Pulping equipment based on shearing, pulp filtering and coarse and fine ball milling in sequence

A technology of refining and filtering, which is applied in pulp beating/refining methods, textiles and papermaking, fiber raw material treatment, etc., can solve the problems of low refining quality and low refining efficiency, and achieve improved refining quality and prevention damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

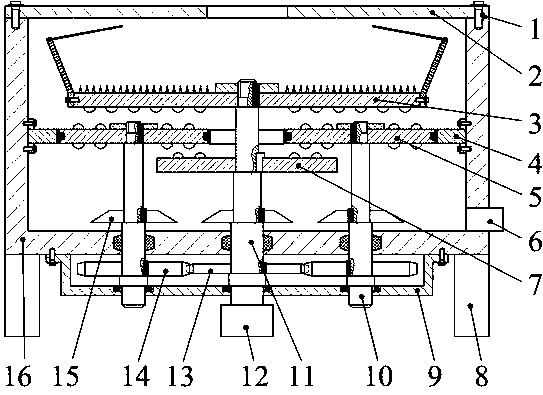

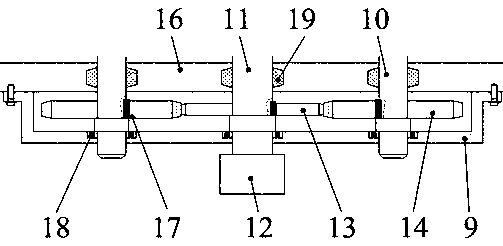

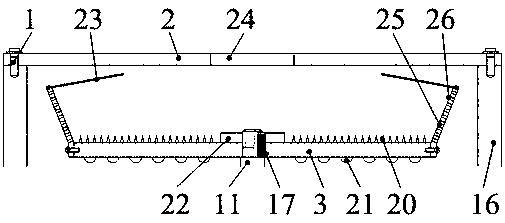

[0038] Such as figure 1 As shown, a kind of refining equipment of the present invention based on first shearing and filtering pulp and then coarse and fine ball milling mainly includes a refining generation device, a power drive device, a shearing and filtering device, a coarse and fine ball milling device and an anti-sedimentation crushing device, The power drive device is located under the pulp generating device, and the shearing and filtering device, the coarse and fine ball milling device and the anti-sedimentation crushing device are installed in the pulp generating device sequentially from top to bottom.

[0039] The present invention realizes the generation and output of refining through the refining generating device, that is, the slurry is cut into pieces and filtered in the grinding cylinder 16 of the refining generating device, and the coarse and fine balls are milled to generate the required refining, and the generated refining is refined. Output from outlet 6; pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com