Assembly type retaining structure connecting device and connecting method thereof

A technology of supporting structure and connecting device, which is applied in basic structure engineering, excavation, sheet pile wall, etc., can solve the problems of long construction period, difficult processing of reinforced concrete waist beam formwork, twisting of steel waist beam, etc. Stiffness can be fully utilized to avoid the effect of overall damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

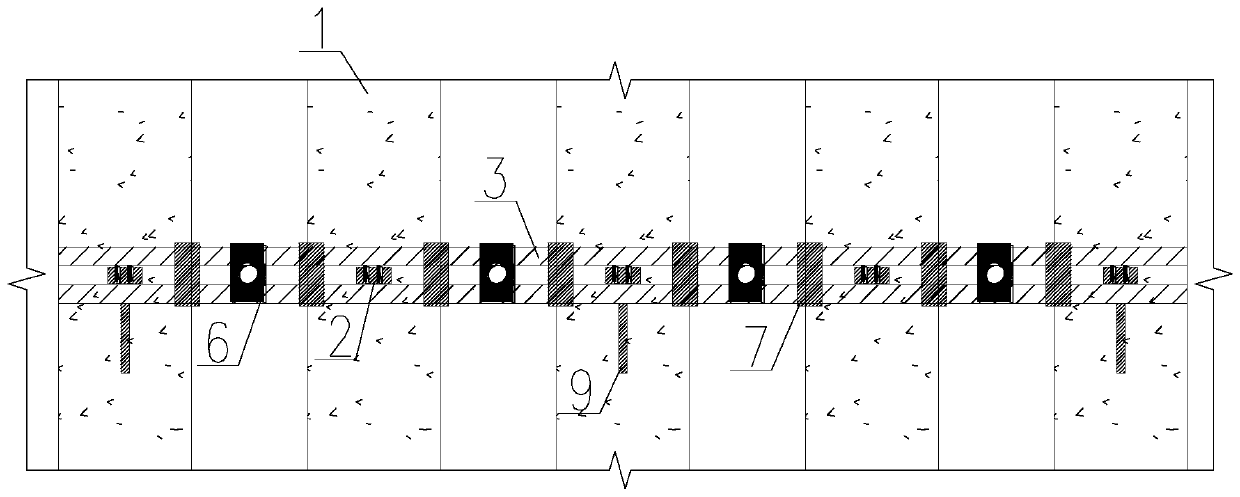

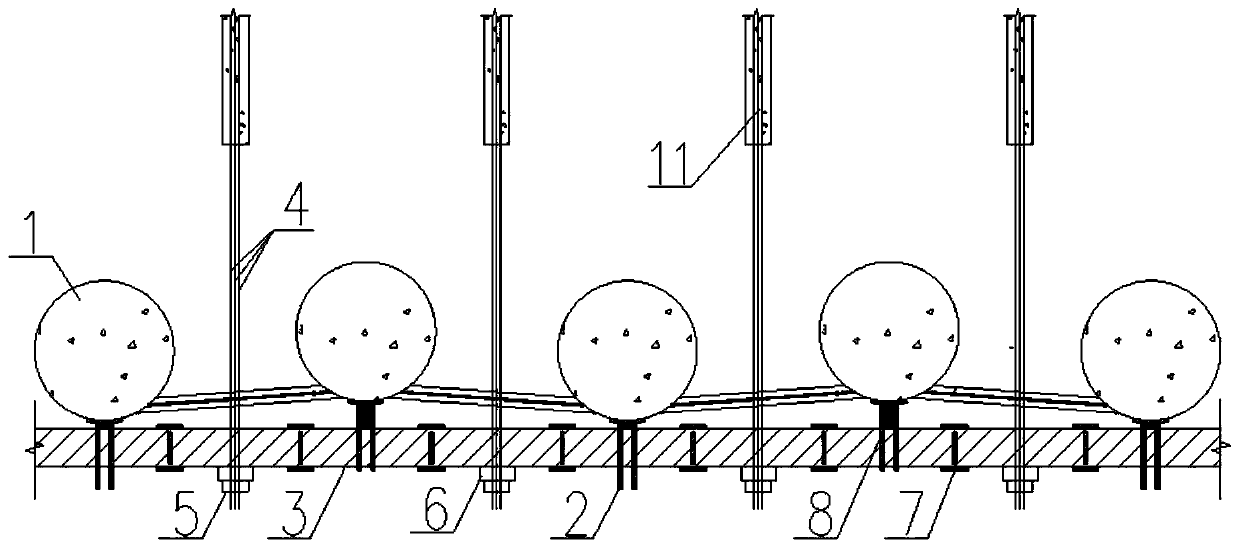

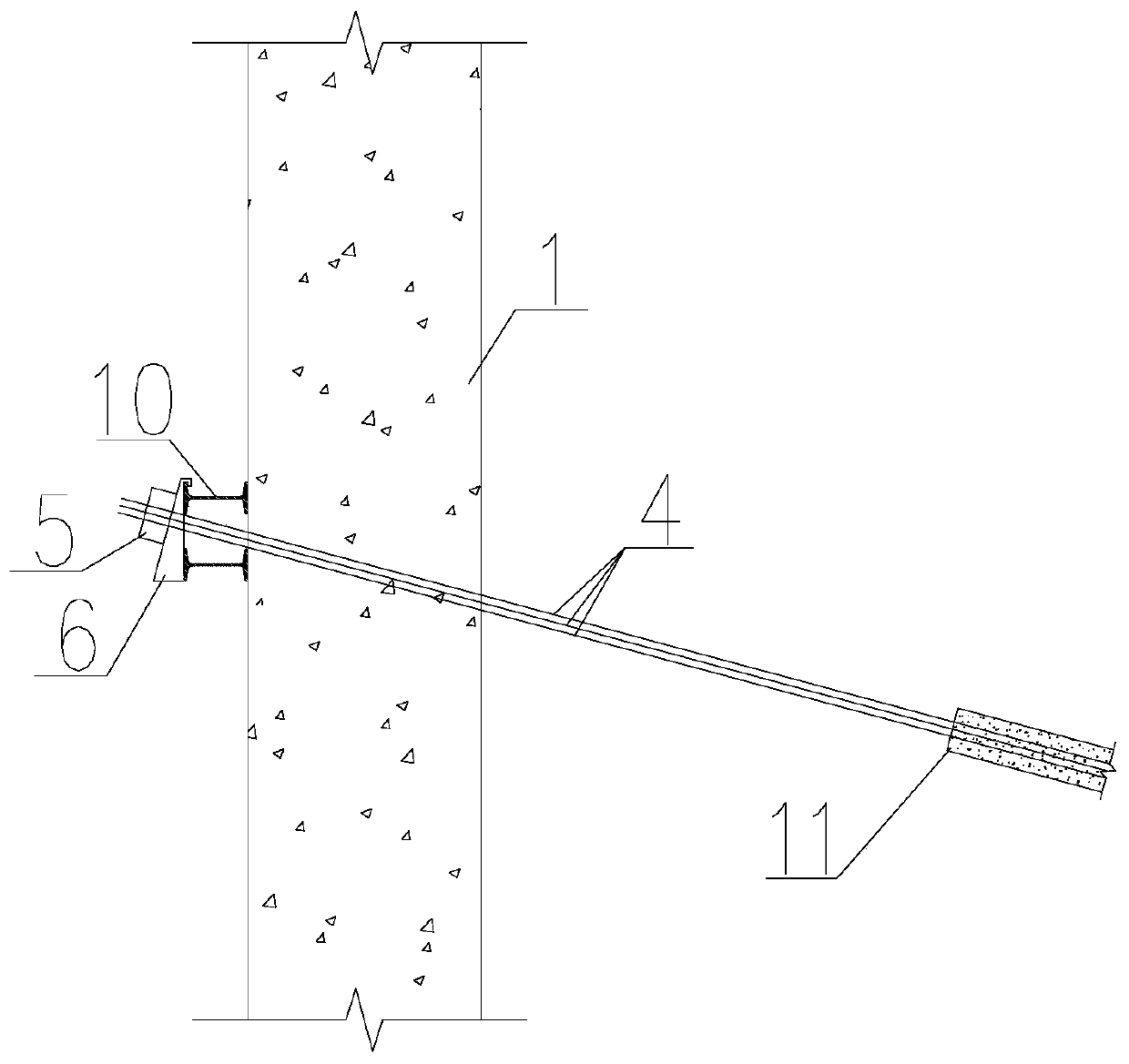

[0043] The present invention is an assembly-type retaining structure connection device, the structure of which is as follows: Figure 1-2 As shown, it includes a plurality of support piles 1 vertically arranged in the rock and soil body, and at least one horizontally placed section steel composite waist is arranged along the length direction of the support pile 1 on the side of the plurality of support piles 1 away from the rock and soil body. The beam 3 and the gap between the section steel composite waist beam 3 are uniformly provided with a plurality of soil retaining member connectors 2, and the soil retaining member connectors 2 are set in one-to-one correspondence with the supporting piles 1, and the other end of the soil retaining member connector 2 is clamped. On the corresponding support pile 1, an anchor cable 11 is arranged between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com