Fabricated steel structure integrated green building and designing and mounting process thereof

A green building and steel structure technology, applied in the direction of buildings, building components, building structures, etc., can solve problems such as complex assembly and fixing methods, delaying construction period, time-consuming and labor-intensive, etc., to improve the stability and safety of the overall structure, Improve structural strength and facilitate assembly and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

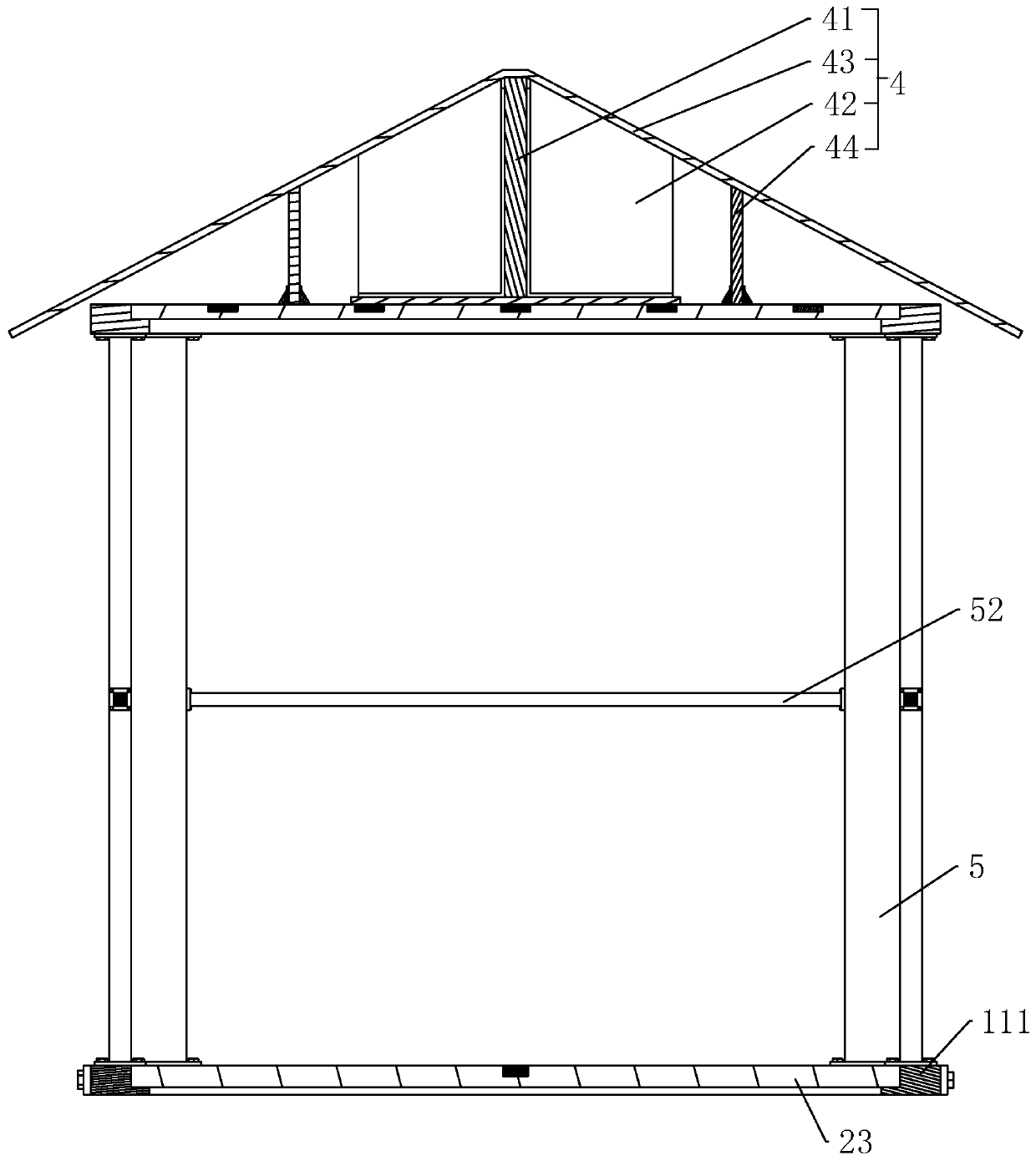

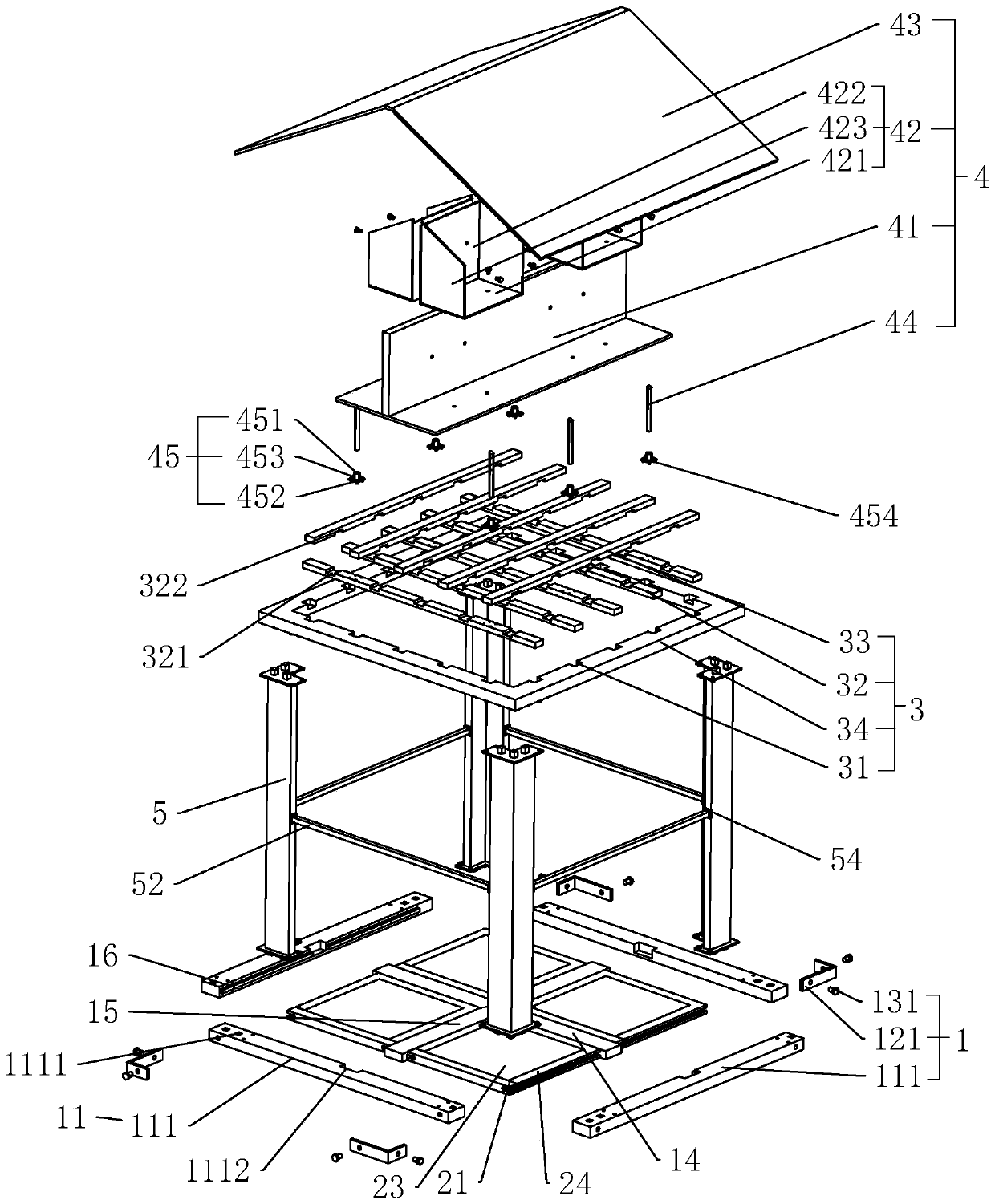

[0052] A prefabricated steel structure integrated green building, refer to figure 2 and image 3 , including a lower mounting base 1, a floor assembly 2 detachably mounted on the lower mounting base 1, a support column 5 detachably mounted on the lower mounting base 1, an upper mounting base 3 detachably mounted on the top of the supporting column 5 and a Mount the roof assembly 4 on top of the seat 3.

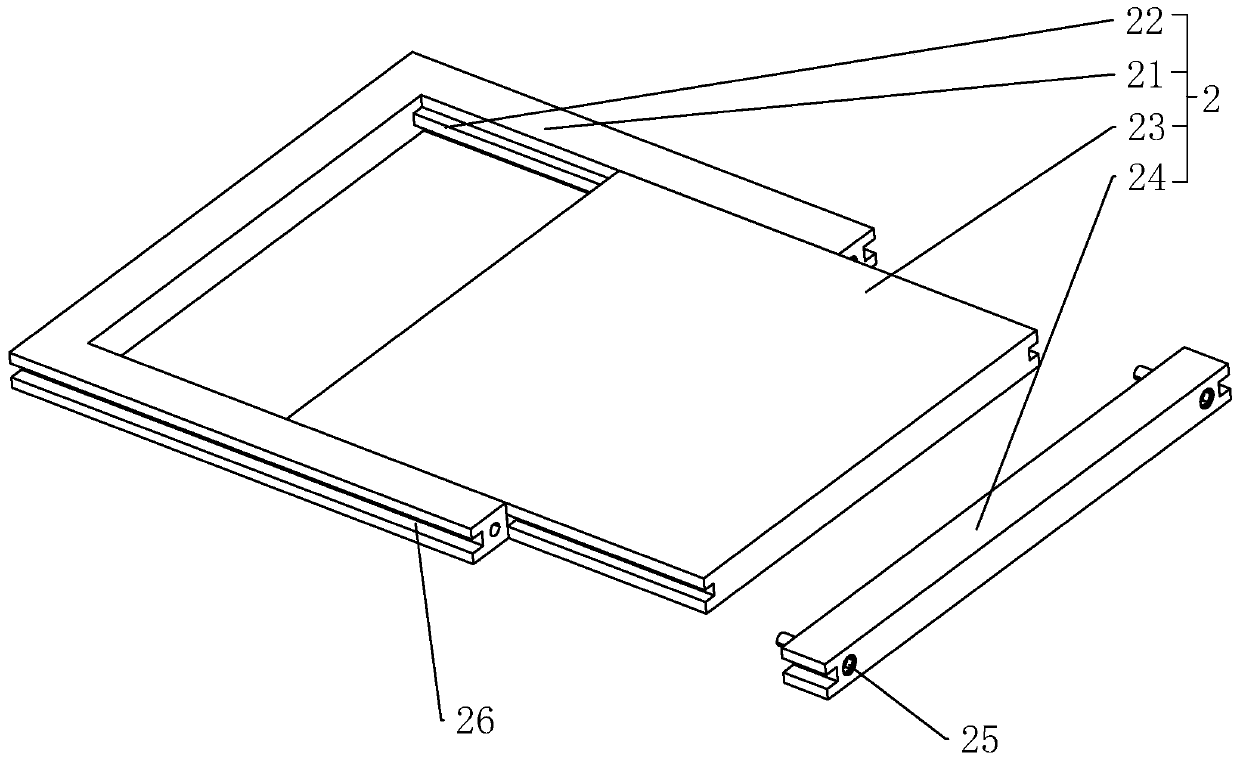

[0053] refer to figure 2 and image 3 The floor assembly 2 includes a mounting frame 21, projections 22 arranged on two opposite side walls of the mounting frame 21, a floor plate 23 slidingly connected to the projections 22, and a mounting plate 24 plugged into one side of the mounting frame 21, The installation frame 21 is arranged in a C shape, and the floor plate 23 is plugged into the installation frame 21 along the length direction of the protrusion 22, and then the installation plate 24 is resisted at the opening of the installation frame 21, and the installation p...

Embodiment 2

[0070] A prefabricated steel structure integrated green building design and installation process applied to Example 1, refer to figure 2, including the following steps:

[0071] S1: Install the floor assembly 2: Insert the floor plate 23 along the length direction of the protrusion 22, then install the installation plate 24 at the opening of the installation frame 21, and install the installation plate 24 on the installation frame 21 by fastening bolts 225 ;

[0072] S2: Install the floor assembly 2 on the lower mounting seat 1: connect the three beams 111 in turn, and cover the joint of the two beams 111 end-to-end with angle steel 121, and use fastening bolts 131 Fix the crossbeam one 111 with the angle steel one 121, install the two floor components 2 on the three crossbeams one 111, install the reinforcing beam one 14 between the two floor components 2, insert one end of the reinforcing beam one 14 into the concave In the slot 31, insert the reinforcing beam 2 15 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com