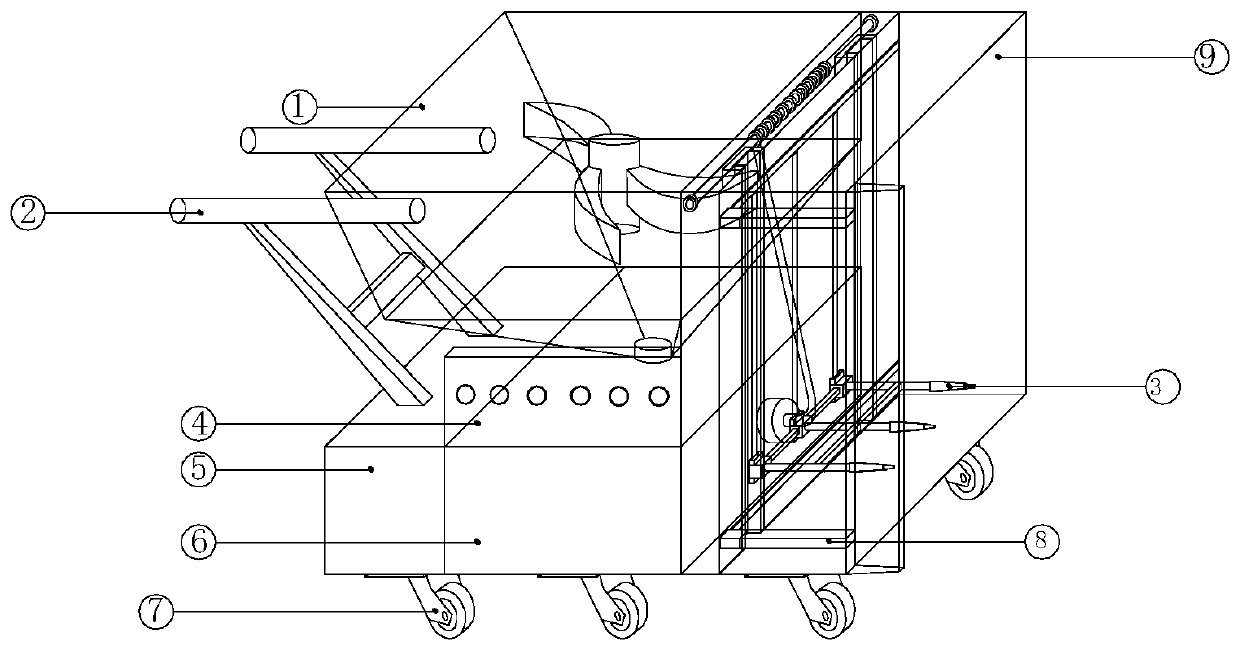

Automatic putty powder brushing device and construction method thereof

A putty powder and brushing technology, which is applied in the direction of construction and building structure, can solve the problems of wasting time and labor, and achieve the effects of convenient operation, labor saving and construction cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

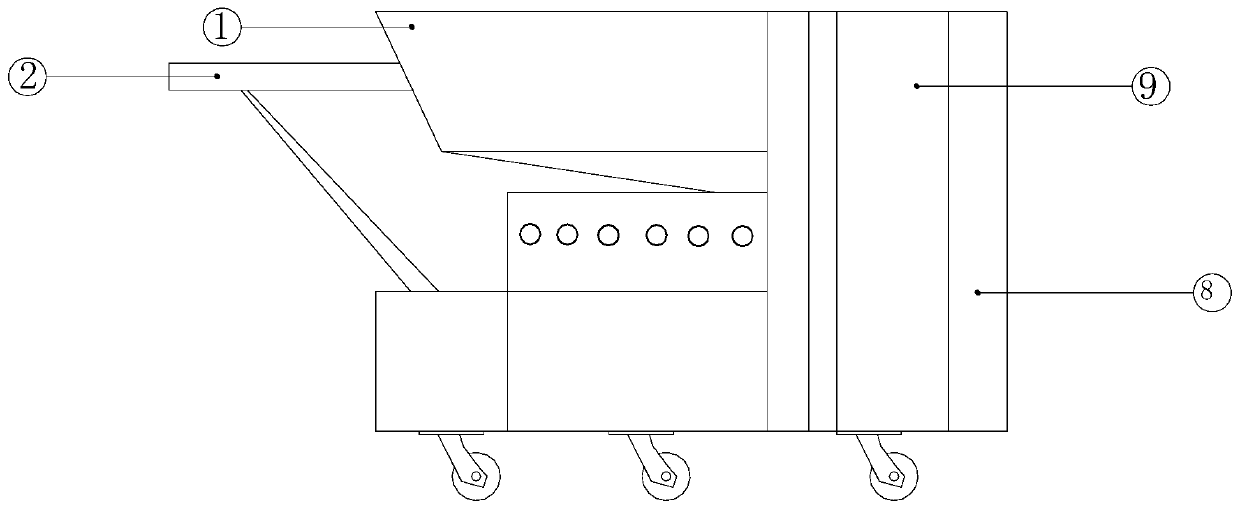

Method used

Image

Examples

Embodiment

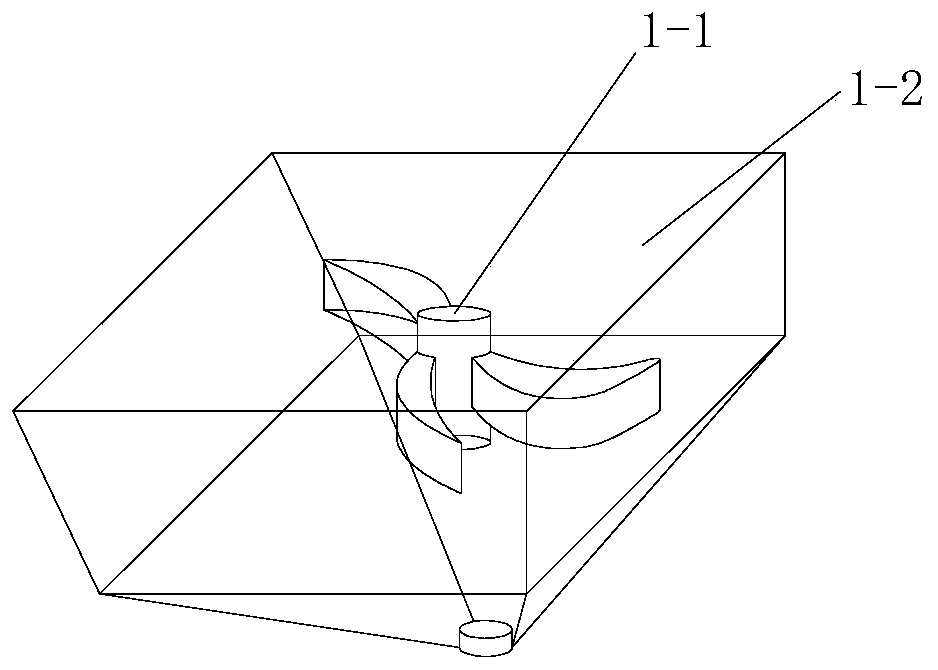

[0042] The embodiment adopts three groups of high-pressure spray guns 3-2, and the three groups of high-pressure spray guns 3-2 are connected and fixed by steel pipes, and the tail is fixed with the longitudinal electric sliding table 3-3. There are three longitudinal slide rails 3-4 and three groups of longitudinal electric sliding tables 3-3.

[0043] The scraper mechanism 8 is arranged at the front end of the lifting frame 9-7 of the front-end lifting mechanism 9, and includes a horizontal electric slide table 8-2, a horizontal slide rail 8-3, and a scraper 8-1. The horizontal slide rail 8- 3. It is horizontally arranged at the upper and lower ends of the lifting frame 9-7, and the scraper 8-1 is vertically arranged to slide left and right on the horizontal slide rail 8-3 driven by the horizontal electric slide table 8-2.

[0044] The scraper 8-1 is a plastic material, and the upper and lower positions of the tail are respectively fixed with two groups of horizontal electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com