Dual-W-shaped combined type metal sealing structure for roller cone bit

A technology of roller cone bit and metal seal, which is applied in construction and other directions, can solve the problems affecting the working efficiency and service life of the drill bit, the abrasive wear of the end face of the metal seal, the unstable working state of the metal seal, etc., to achieve enhanced reliability and overall performance, small offset, and the effect of reducing axial and radial vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

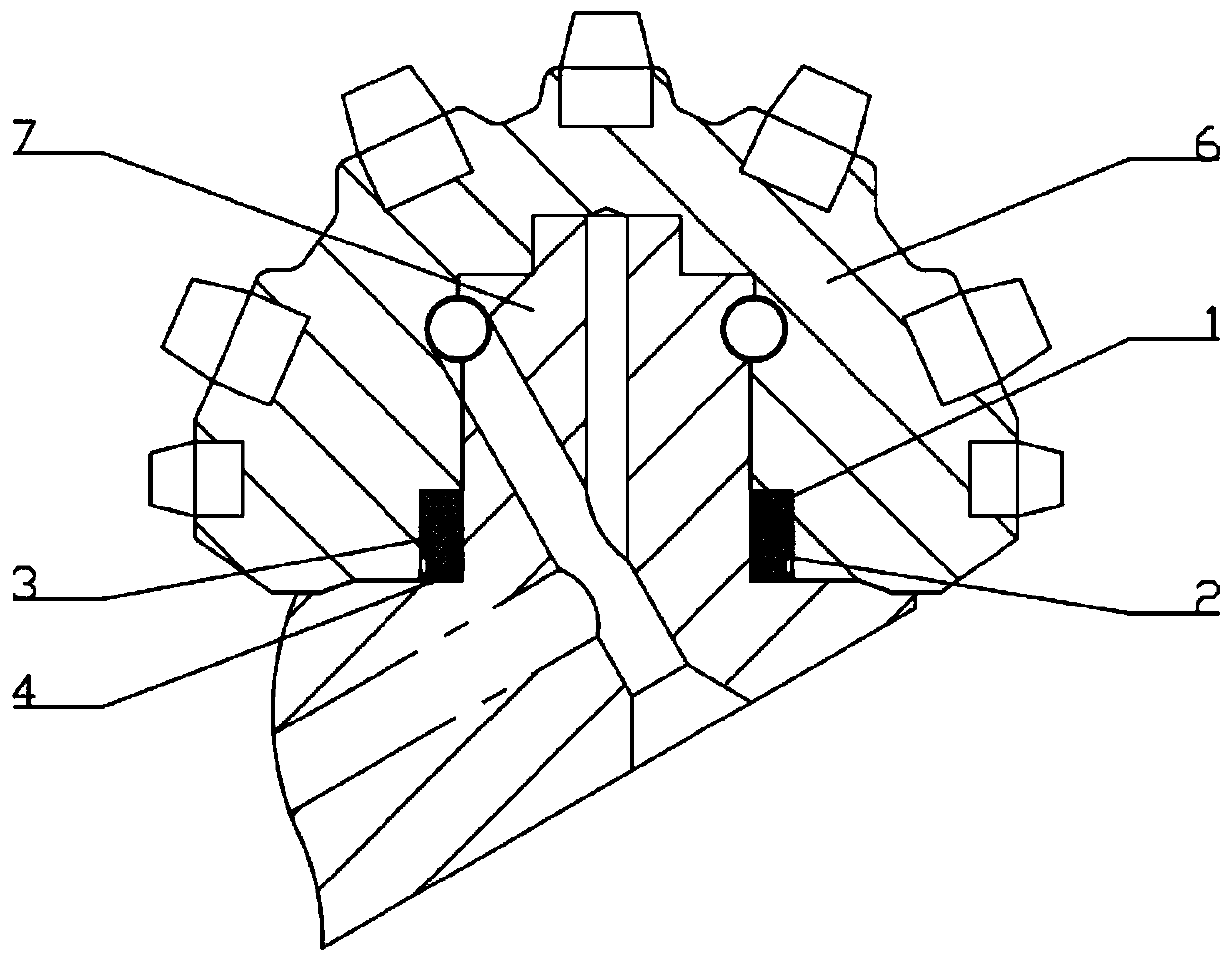

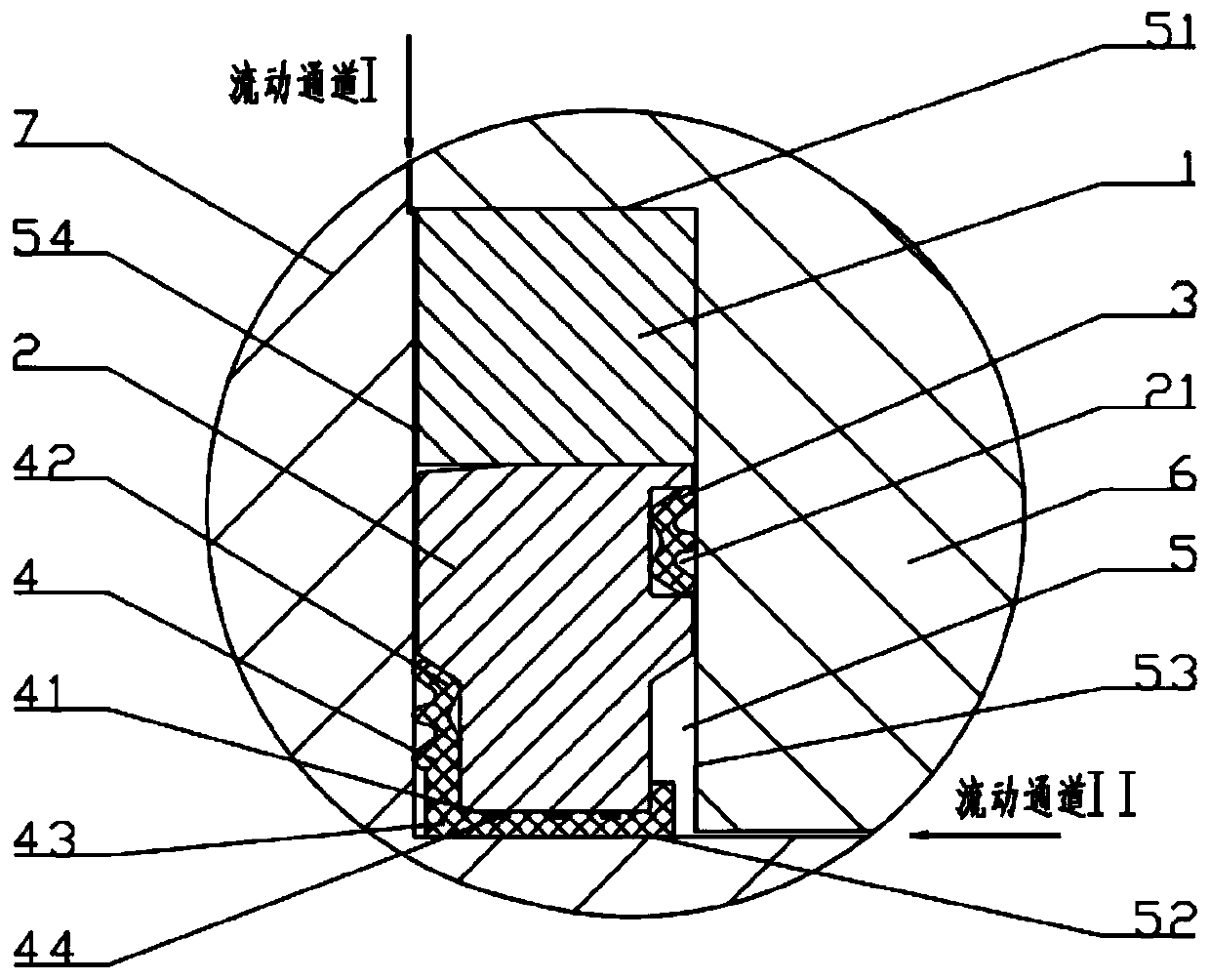

[0022] Embodiment 1 The double W-shaped combined metal seal structure for a roller cone bit according to the present invention includes a dynamic seal ring 1 , a static seal ring 2 , an outer W-shaped rubber ring 3 and an inner W shaped rubber ring 4 . The dynamic sealing ring 1 is located on the top of the sealing cavity 5, and is interference-fitted in the inner hole of the cone 6, and rotates together with the cone 6. The sealed cavity 5 is surrounded by the inner hole of the cone 6 and the root of the palm journal 7, and includes an upper end surface 51, a lower end surface 52, an outer cylindrical surface 53 and an inner cylindrical surface 54. The dynamic sealing ring 1 and the static sealing ring 2 rotate relatively, and the end faces cooperate with each other to form a dynamic sealing surface. The outer cylindrical surface of the upper part of the static sealing ring 2 is provided with an outer rectangular groove 21, the outer rectangular groove 21 is embedded with an ...

Embodiment 2

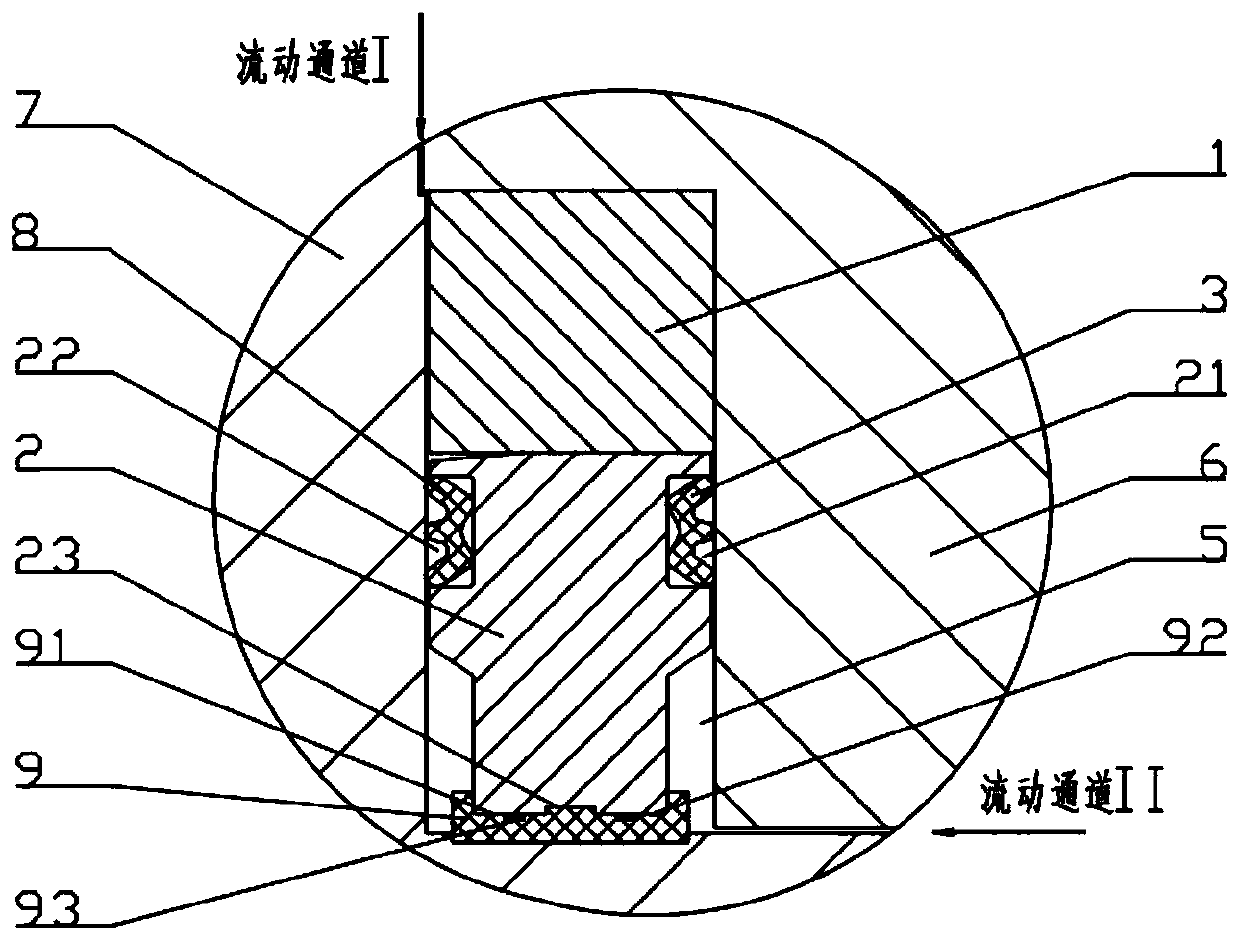

[0023] Embodiment 2 On the basis of the above-mentioned double W-type combined metal seal structure for the roller cone bit of the present invention, the setting and cooperation of the W-shaped rubber ring and the rubber support ring are changed, including the dynamic seal ring 1 and the static seal ring 2 , Outer W-shaped rubber ring 3, inner W-shaped rubber ring 8 and rubber support ring 9. The dynamic sealing ring 1 is located on the top of the sealing cavity 5, and is interference-fitted in the inner hole of the cone 6, and rotates together with the cone 6. The sealed cavity 5 is surrounded by the inner hole of the cone 6 and the root of the palm journal 7, and includes an upper end surface 51, a lower end surface 52, an outer cylindrical surface 53 and an inner cylindrical surface 54. The dynamic sealing ring 1 and the static sealing ring 2 rotate relatively, and the end faces cooperate with each other to form a dynamic sealing surface. The outer cylindrical surface and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com