Multi-line ground-contacting demarcation device

The technology of a line throwing instrument and instrument is applied in the field of positioning laser tools for building interior decoration and construction, which can solve the problems that the instrument is difficult to find the center accurately, cannot conveniently mark the function, and is time-consuming and labor-intensive, and achieves the effect of eliminating the influence of the positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through the description of the drawings and specific implementation examples.

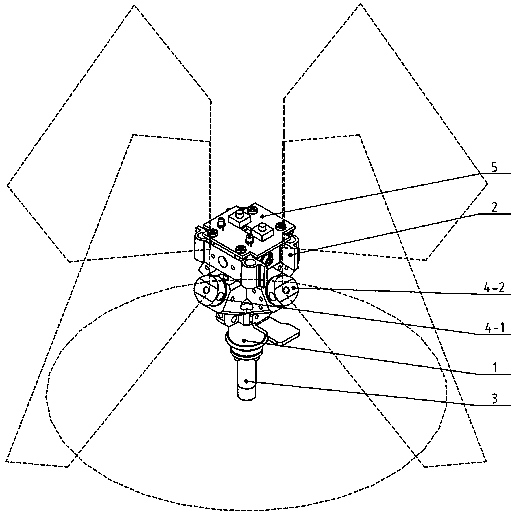

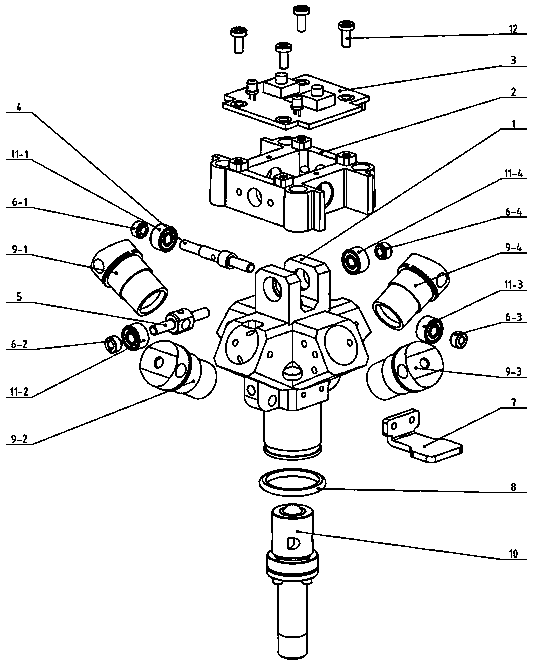

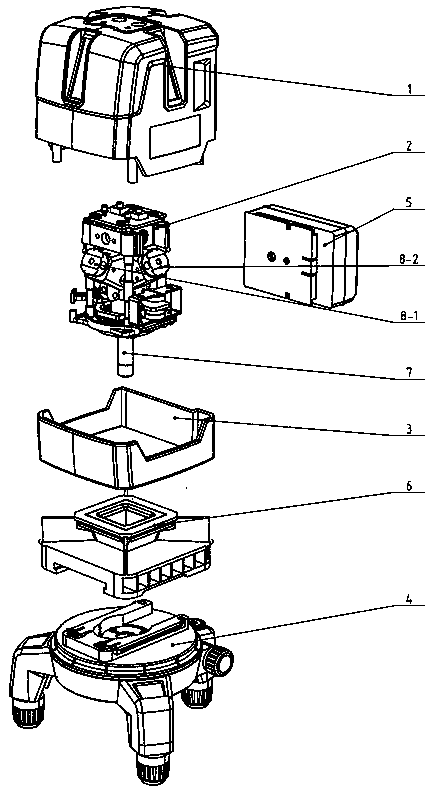

[0018] A multi-line sticking line throwing instrument, such as figure 1 As shown, the lower laser module-3 forming the horizontal positioning surface and the lower point is provided, and four vertical laser modules 4-1, 4-2, 4-3, which are perpendicular to the horizontal positioning surface and are orthogonal to each other, 4-4. The beam emitted by the lower laser head is located at the bottom of the multi-line ground-attached line projection instrument, and the laser beam forms a 360° positioning plane between the main body of the ground wall instrument and the ground. The mechanism can also be installed with a top laser head, the top laser module is installed on the pendulum above the cross shaft, and the top of the pendulum body c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com