Continuous casting billet barrier-free hidden weighing device and using method thereof

A weighing device and barrier-free technology, which is applied in the direction of measuring devices, weighing equipment and weighing of materials with special properties/forms, can solve the problem of not taking into account the influence of longitudinal impact and external horizontal horizontal impact, and occupying a large area Space and other issues, to achieve the effect of cost saving and high-precision weighing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

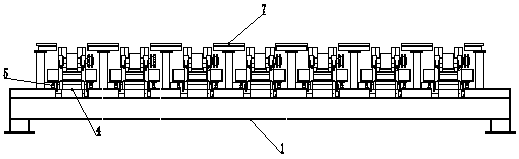

[0021] Embodiment 1: as Figure 1-5 As shown, the present invention includes at least two horizontally spaced main beams 1, several roller beams 2 erected on the main beams, several roller wheels 3 installed on the roller beams for transporting billets, and rollers The road beam suspension device 4, the roller beam suspension device includes a major axis 41 that passes through the roller beam in the radial direction and cooperates with the roller beam in a gap, and is provided below the major axis parallel to the major axis and coincides with the vertical line. The short axis 42 of the short axis is distributed symmetrically about the center with two roller beam fixing seats 43 for supporting the roller beam and the bottom of which is in contact with the main beam. The bottom of the roller beam fixing seat is provided with a The arched opening groove 44 contained in the short shaft, the two ends of the short shaft are covered with a hanging plate 45, the two ends of the long a...

Embodiment 2

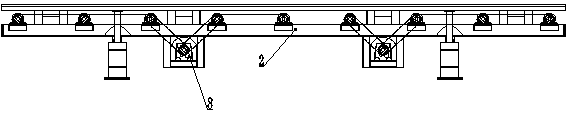

[0022] Embodiment 2: as figure 2 As shown, the rollers are divided into two groups of rollers along the length direction of the roller table beam, and each group of rollers includes 5 rollers, and these 5 rollers can be divided into the first 3 rollers and the rear 2 rollers , the first 3 rollers are connected with the motor 8 transmission located below the roller table beam through the belt, and the same rear 2 rollers are connected with the motor transmission through the belt. Another group of rollers is set transmission like this.

Embodiment 3

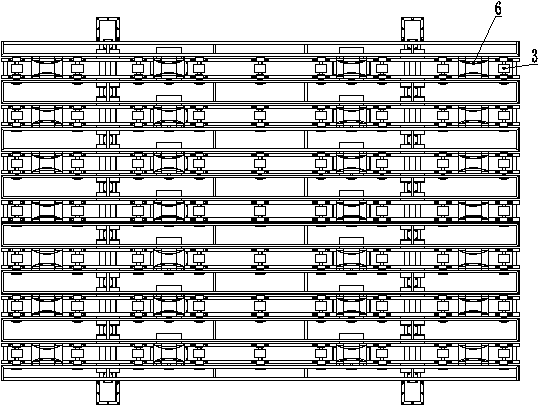

[0023] Embodiment 3: In order to prevent the billet from shifting on the roller table beam, the two side walls of the roller table beam are provided with inwardly curved guide plates 6 respectively. Make sure the billet is always advancing in the center of the roller beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com