Built-in magnet permanent magnet motor rotor, motor and vehicle

A permanent magnet motor, built-in technology, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electromechanical devices, etc., can solve the problems of difficulty in meeting large speed range speed regulation, poor combination flexibility, high manufacturing cost, etc., to meet performance requirements , reduce production costs, and meet the effect of weak magnetic demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

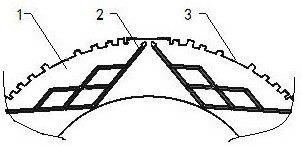

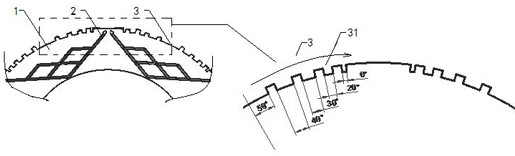

[0058] This embodiment provides a built-in magnetic steel permanent magnet motor rotor, such as figure 1 As shown, a core 1 is included; several magnetic steel units 2 are arranged in the core 1, and the magnetic steel units 2 are distributed in the core 1 with the center of the core as a symmetrical center. The core 1 is processed into a structure with a plurality of magnetic steel slots inside, and the magnetic steel slots are used to accommodate the magnetic steel unit 2 .

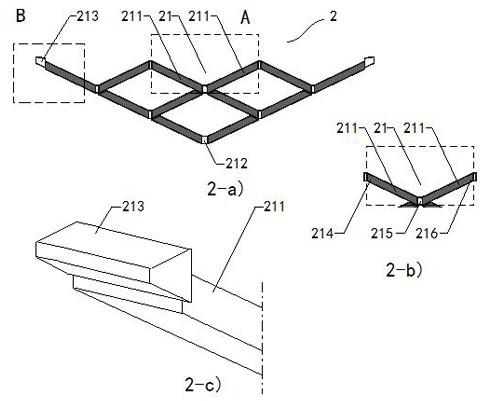

[0059] Such as figure 2 The shown magnetic steel unit 2 contains 6 V-shaped magnetic steels 21, such as figure 2 The structure in the dotted frame area A is a V-shaped magnetic steel 21 , and the V-shaped magnetic steel 21 includes a first end 214 , a second end 216 and a connection end 215 between the first end 214 and the second end 216 .

[0060] Such as figure 1 and figure 2 As shown, the V-shaped magnets 21 in the magnet unit 2 are arranged into three layers from the inside of the core to th...

Embodiment 2

[0074] This embodiment provides a motor, including a stator; and the rotor of the built-in magnetic steel permanent magnet motor.

Embodiment 3

[0076] This embodiment provides a vehicle, including: a motor, the motor includes a stator and the rotor of the built-in magnetic steel permanent magnet motor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com