Double-layer winding wire embedding method

A double-layer winding and lower-layer technology is applied in the direction of electric components, manufacturing motor generators, electrical components, etc. It can solve the problems of poor joint connection reliability, long copper wires, troublesome wire embedding process, etc., so as to improve reliability and practicability Strong, material and man-hour saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

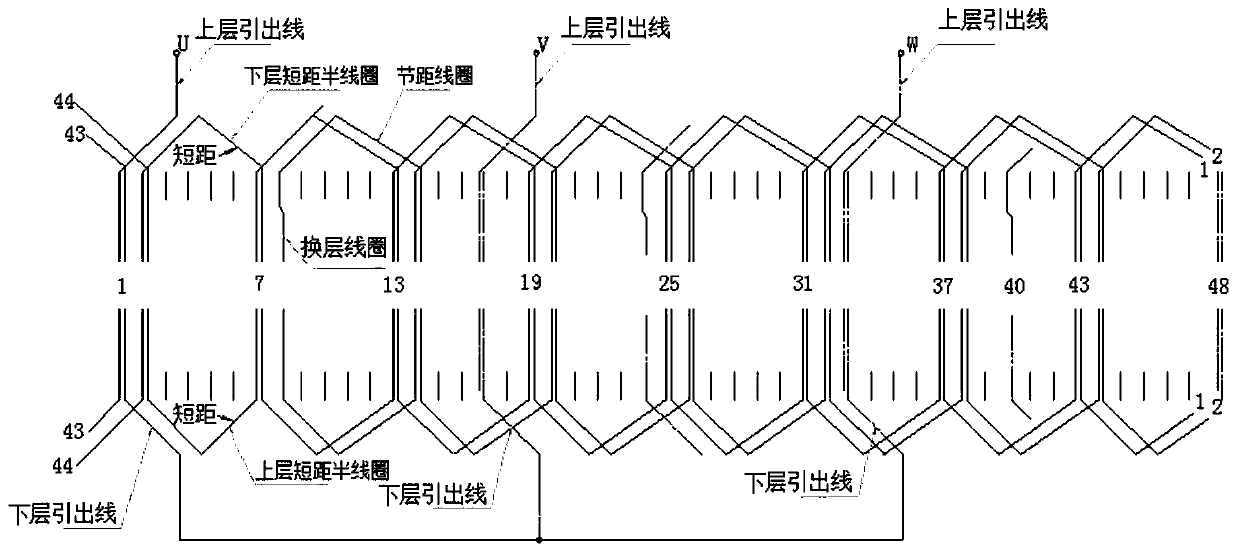

[0031] like Figure 1-6 As shown, the motor has 48 slots, the pitch is 1 to 7, the short pitch is 1 to 6, and the number of slots per pole and phase is 2. figure 1 Indicates the embedded line of the U phase, the other two phases are the same as the U phase, but the slot number is different.

[0032] like figure 1 As shown in the wiring diagram, the embedding steps are as follows:

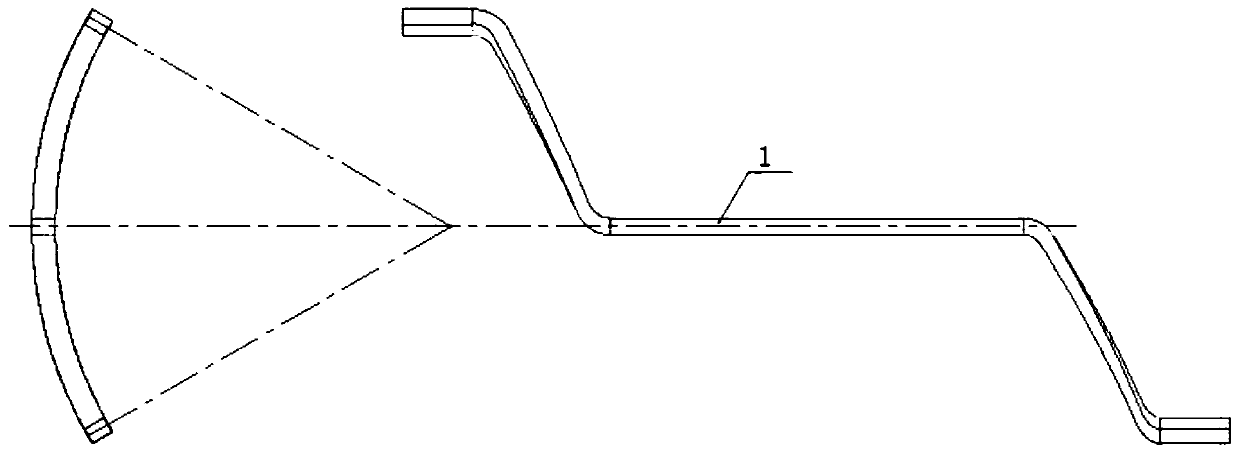

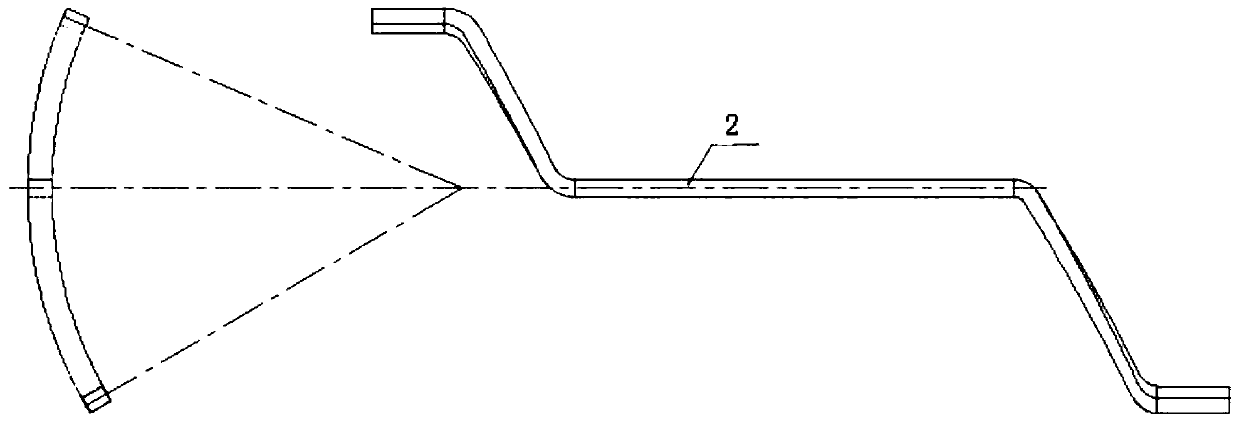

[0033] S1: use first figure 2 The shown pitch coil 1 moves from the first slot to the left and starts to insert the wire for one week, and the order of the insertion is as follows: 1-43'-37-31'-25-19'-13-7' (the ones with 'indicate the lower layer coils edge); when the ruled line returns to the lower edge of the lower layer short-distance half-coil 3, use Figure 4 The short-distance half-coil 3 of the lower layer shown is moved to the right by 1 slot;

[0034] S2: continue to use figure 2 The shown pitch coil 1 moves to the left and inserts the wire again for one week, and the order of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com