Single cabinet modular server liquid cooling system and control method thereof

A server and modular technology, which is applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of complex construction and complicated liquid cooling system, achieve simple construction and improve the space utilization of the computer room Rate, reduce the effect of PUE value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

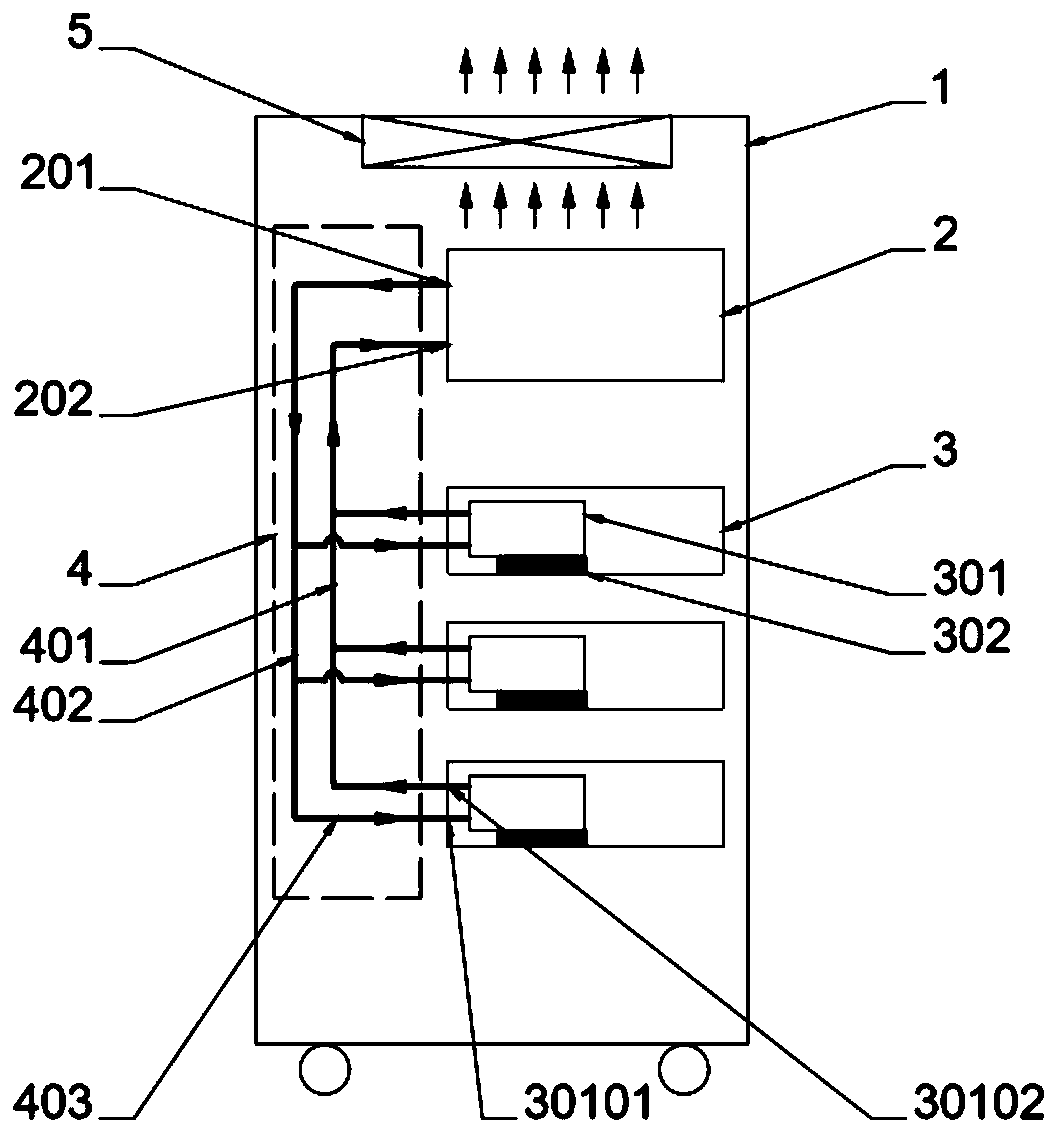

[0043] see figure 1 , a single cabinet modular server liquid cooling system, comprising a cabinet body 1, a liquid cooling module 2, a liquid cooling server 3, a cooling liquid distribution unit 4, and a cabinet cooling fan 5;

[0044]The liquid cooling module 2 is installed on the top of the cabinet body 1 , and the cooling liquid distribution unit 4 is installed on the rear side of the cabinet body 1 . One or more liquid-cooled servers 3 are installed in the cabinet body 1, located at the lower end of the liquid-cooled module 2, and the cabinet cooling fan is placed on the top of the cabinet. This setting is suitable for server cabinets with a small height, which is conducive to the hot air flow avoiding the servers and quickly exiting the cabinet.

Embodiment 2

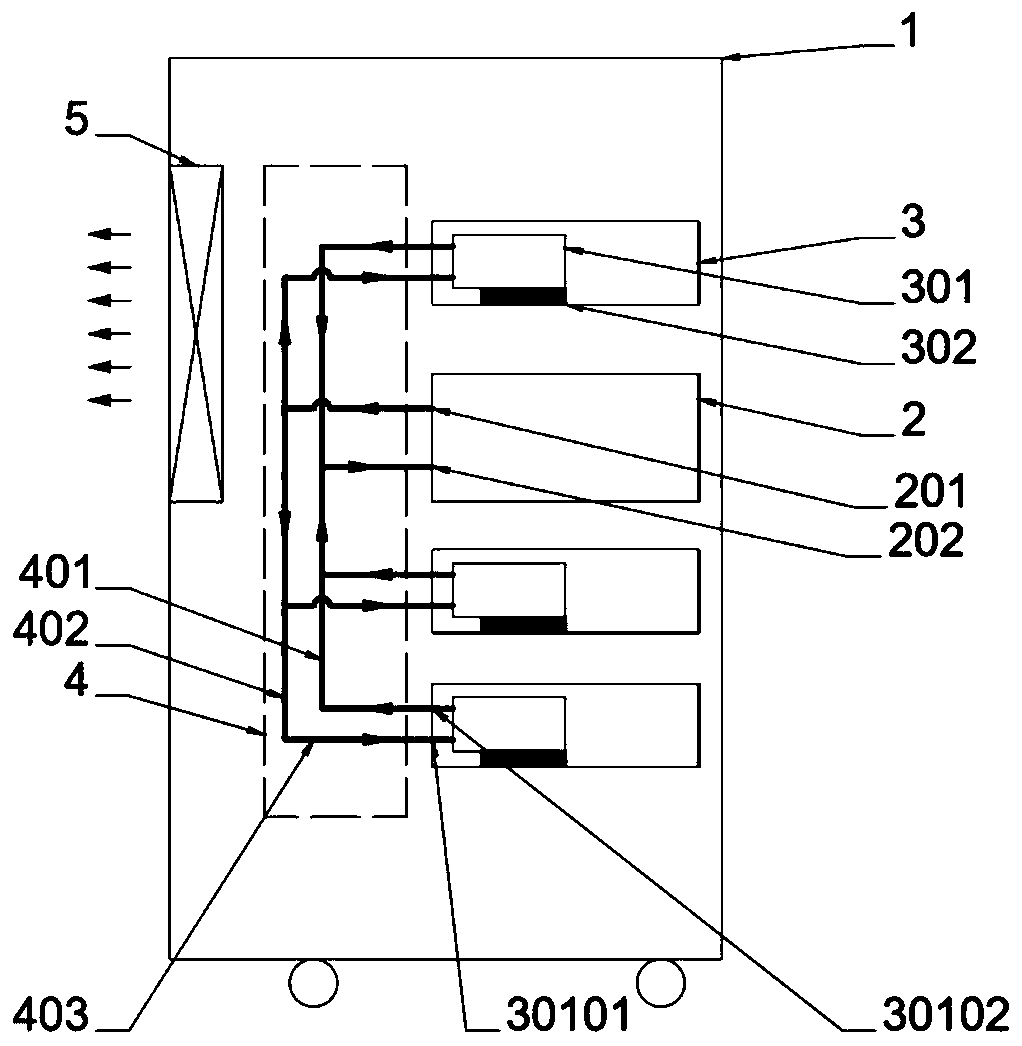

[0046] see figure 2 , a single-cabinet modular server liquid cooling system, including a cabinet body 1, a liquid cooling module 2, a liquid cooling server 3, a cooling liquid distribution unit 4, and a cabinet cooling fan 5; the liquid cooling module 2 is installed in the cabinet body 1 In the middle layer, the coolant distribution unit 4 is installed on the rear side of the cabinet body 1, and one or more liquid-cooled servers 3 are installed in the cabinet body 1, partly at the upper end of the liquid-cooling module 2, and partly at the lower end of the liquid-cooling module 2 , the cabinet cooling fan is placed on the side of the cabinet. This setting is suitable for server cabinets with a high height, and placing the middle layer facilitates the maintenance of the liquid cooling module.

Embodiment 3

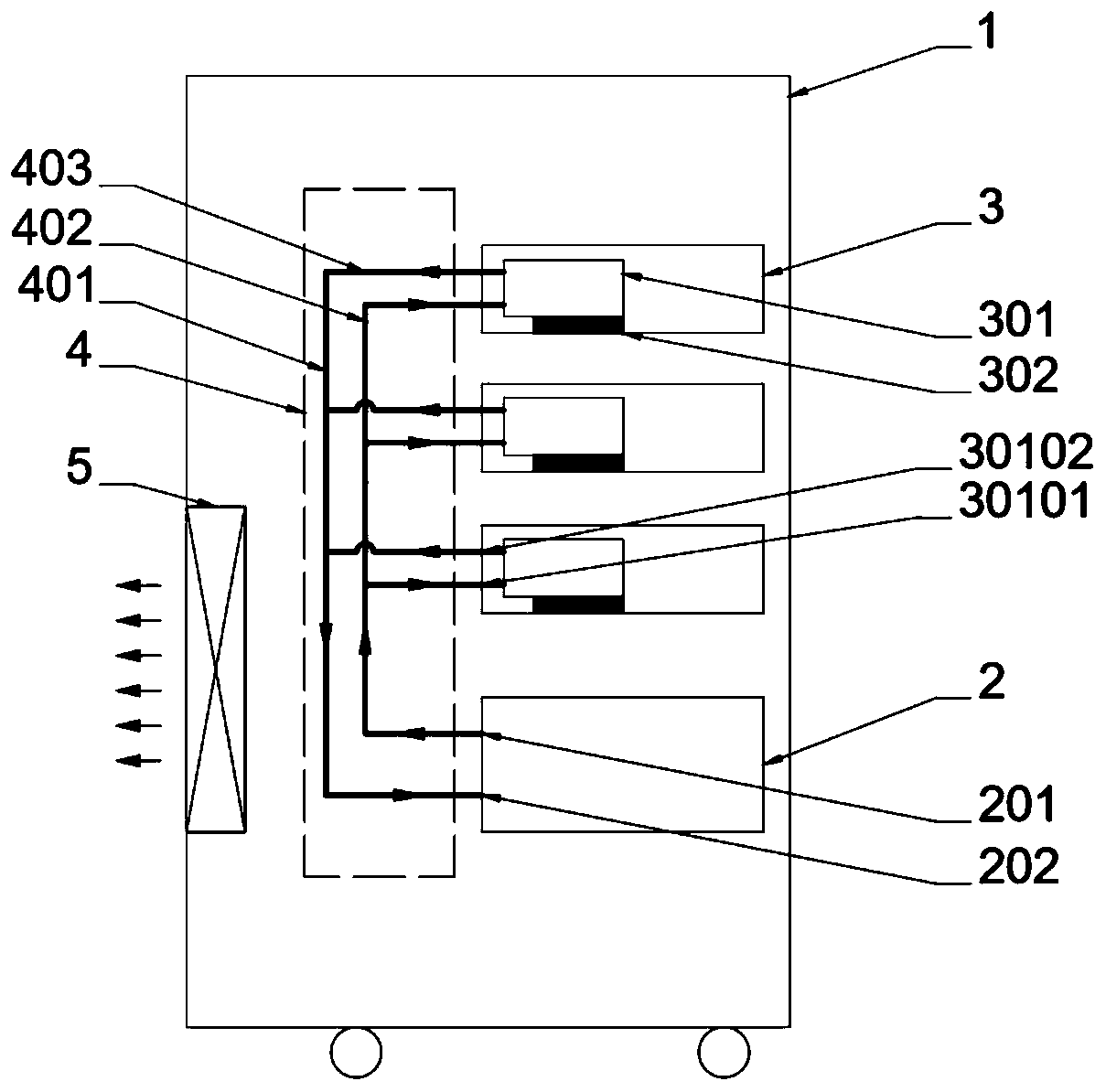

[0048] see image 3 , a single-cabinet modular server liquid cooling system, including a cabinet body 1, a liquid cooling module 2, a liquid cooling server 3, a cooling liquid distribution unit 4, and a cabinet cooling fan 5; the liquid cooling module 2 is installed in the cabinet body 1 On the bottom floor, the cooling liquid distribution unit 4 is installed on the rear side of the cabinet body 1, one or more liquid-cooled servers 3 are installed in the cabinet body 1, and are located at the upper end of the liquid-cooling module 2, and the cabinet cooling fan is placed on the side of the cabinet . This setting is suitable for cabinets with high server density. When installed in a cabinet with high server density, a large-capacity water tank must be installed on the liquid cooling module. Placing the bottom layer will help improve system reliability.

[0049] The liquid cooling module 2 is used to reduce the temperature of the coolant and ensure that the coolant can circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com