ABS based resin and its prepn method

A kind of technology of base resin and molded product, applied in the field of ABS base resin and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

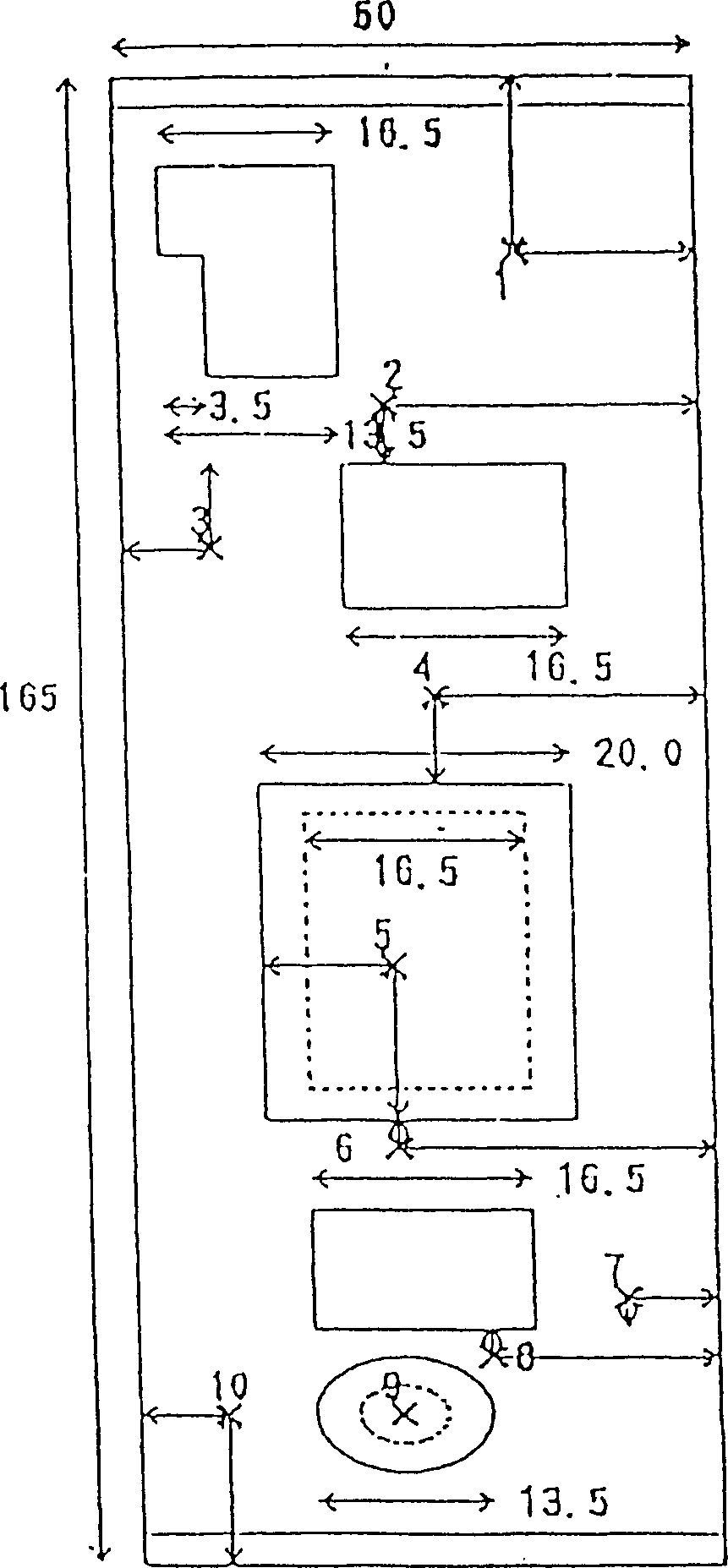

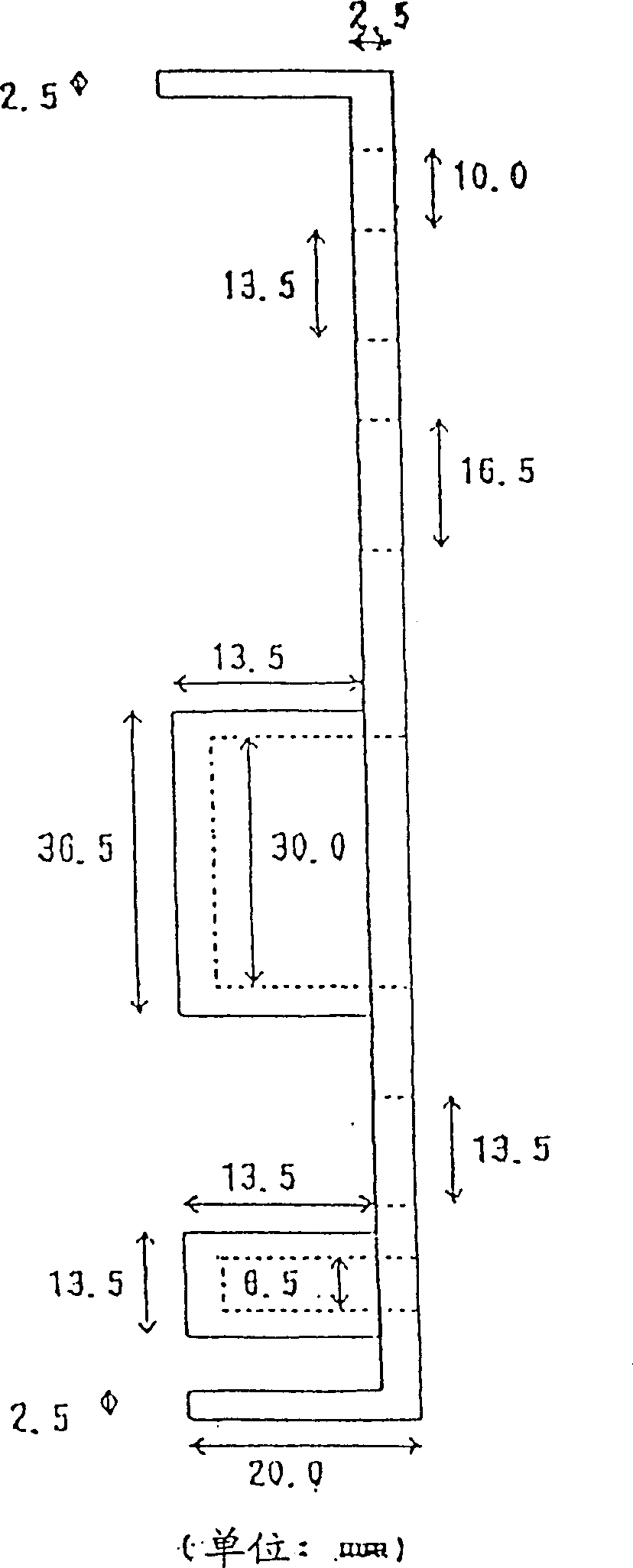

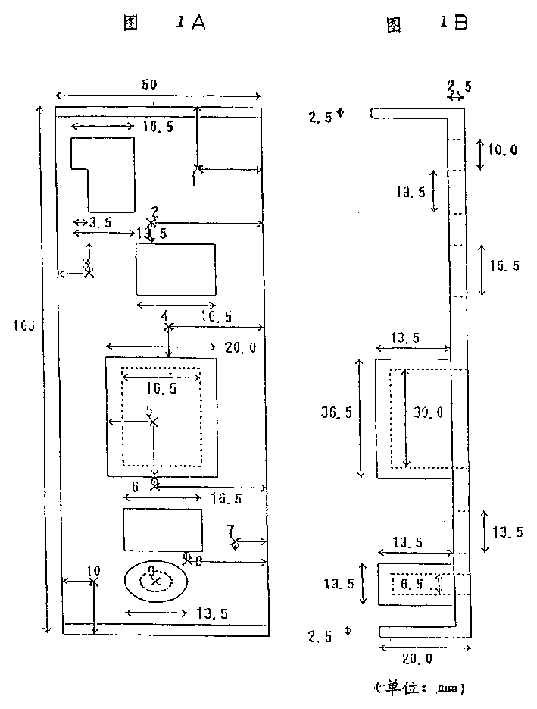

Image

Examples

Embodiment 0

[0196] Example 0 describes a method of controlling the quality of ABS-based resins.

[0197] The preparation method of a.ABS base resin

[0198] Prepare single-batch solution every hour, and this solution is made of 75.5 parts by weight styrene, 24.5 parts by weight acrylonitrile, 5 parts by weight ethylbenzene, 7 parts by weight rubber polymer (styrene-butadiene block copolymer, when 5wt% In the form of a styrene solution, when measured at 25°C, its solution viscosity is 10 centistokes (cst)), 0.05 parts by weight of 1,1-bis(tert-butyl peroxide)-3,3,5-trimethyl Composition of cyclohexane (as organic peroxide) and 0.2 parts by weight of mercaptan. The solution thus obtained was polymerized in a three-stage reactor consisting of three stirred polymerization tanks arranged in a row.

[0199]Each batch of solution thus prepared was fed continuously to the first kettle. In the first tank, the stirring speed and reaction temperature were set at 350 rpm and 110°C, respectively. ...

Embodiment A

[0204] Example A describes an illustrative preparation of an ABS-based resin (A) which gives moldings with a high gloss with slight unevenness.

[0205] The preparation method of a.ABS base resin

[0206] Prepare single-batch solution, this solution is made of 75.5 parts by weight styrene, 24.5 parts by weight acrylonitrile, 5 parts by weight ethylbenzene, 7 parts by weight rubber polymer (styrene-butadiene block copolymer, with 5wt% styrene The solution form has a solution viscosity of 10 centistokes when measured at 25° C.), 0.05 parts by weight of 1,1-bis(tert-butylperoxy)-3,3,5-trimethylcyclohexane (as an organic peroxide ) and 0.2 parts by weight of mercaptan. The solution thus obtained was in the same three-stage stirred series reactor as used in Example 0-1.

[0207] The batch of solutions thus prepared was continuously fed into the first polymerization reactor. In the reactor, the stirring speed and reaction temperature were set at 70-400 rpm and 110° C., respective...

Embodiment A-1

[0211] Through an extruder, 50 parts by weight of the polymer sample α1 and 50 parts by weight of the polymer sample α2 were melted and kneaded. The material thus obtained was injection molded at a cylinder temperature of 230°C and a mold temperature of 50°C. The molded article thus obtained was found to contain 0.8% of B particles and had a gloss value with a standard deviation as low as 3.0%, indicating slight unevenness in gloss. The results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com