Pomelo picker

A technology of picking device and grapefruit, applied in the field of grapefruit picking device, can solve the problems of low picking efficiency, easy falling off the ground and injury to picking personnel, high picking risk, etc., so as to improve picking efficiency, reduce picking risk, and increase frictional force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

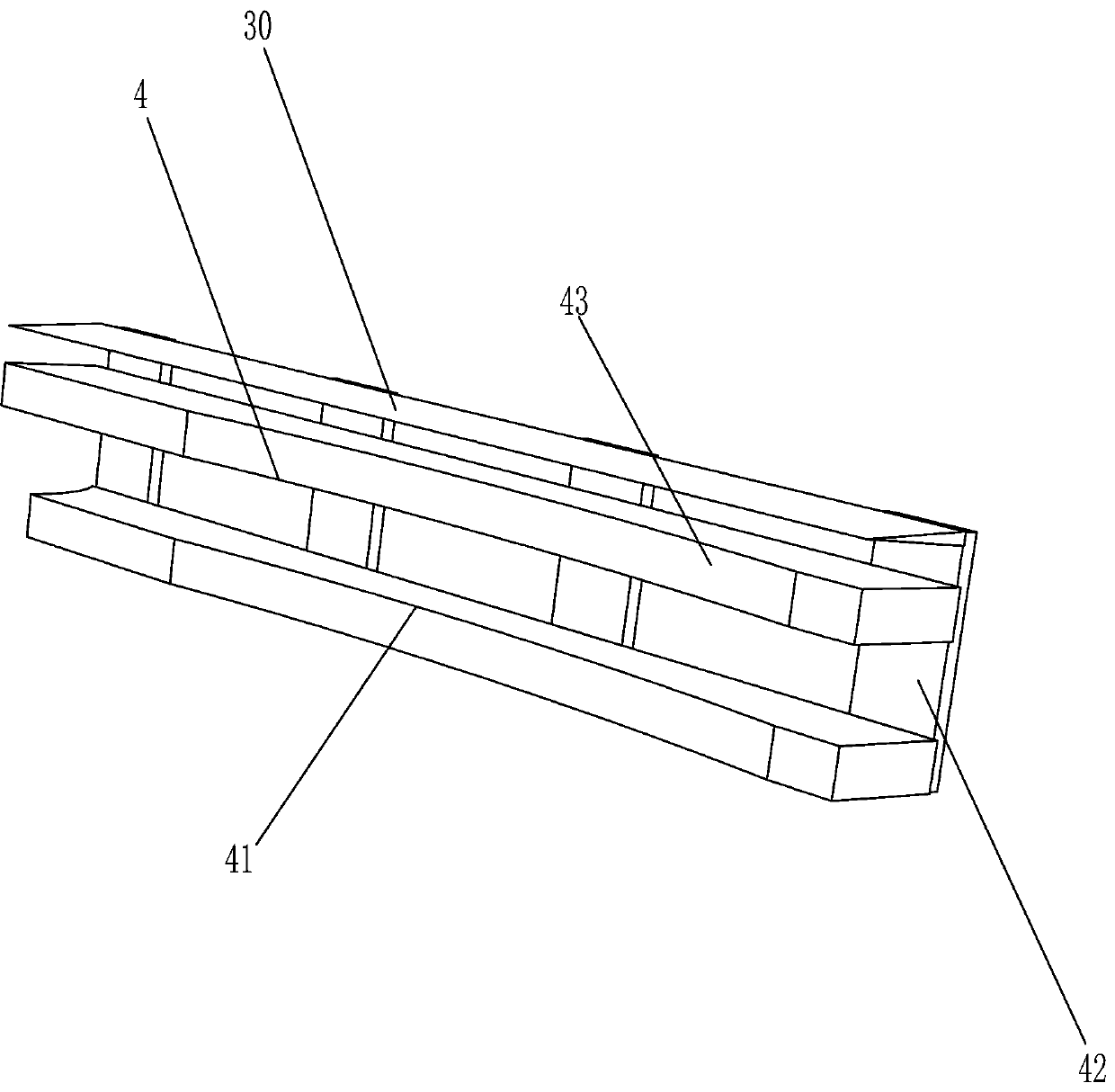

[0029] A grapefruit picker such as Figure 1-6 As shown, it includes a hollow tube 1, a joystick 2, a handle 21, a movable knife 3, a fixed knife 30 and a clamping mechanism 4. The hollow pipe 1 is rotatably connected with a joystick 2, and the bottom end of the joystick 2 is connected with a handle. 21. A movable cutter 3 is connected to the upper part of the joystick 2, and the movable cutter 3 is located above the hollow tube 1. A clamping mechanism 4 is installed on the outer surface of the hollow tube 1, and a fixed cutter is connected to the clamping part of the clamping mechanism 4. 30, the fixed cutter 30 cooperates with the movable cutter 3.

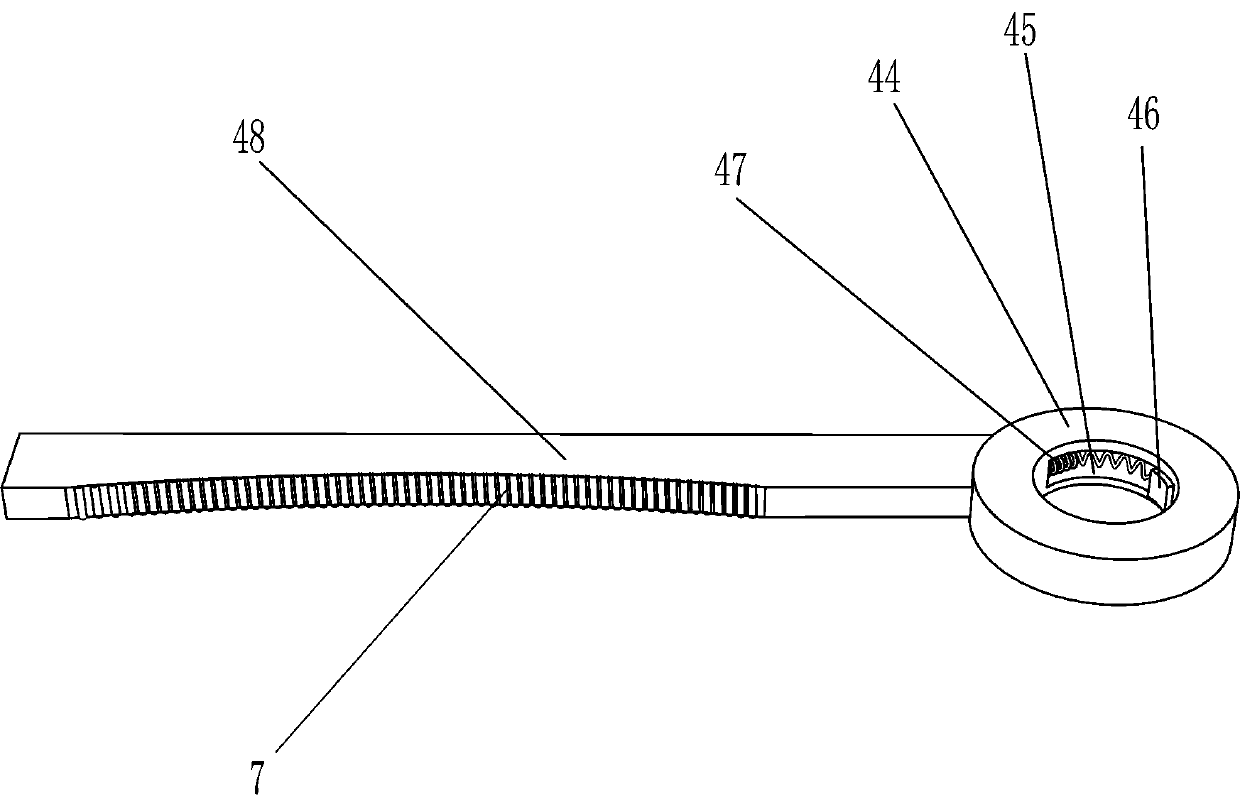

[0030] The clamping mechanism 4 includes a first fixed clamp bar 41, a connecting plate 42, a second fixed clamp plate 43, a fixed ring 44, a slide block 46, a compression spring 47 and a movable clamp bar 48, and the left side of the first fixed clamp bar 41 Connected to the upper side of the outer surface of the hollow tube 1...

Embodiment 2

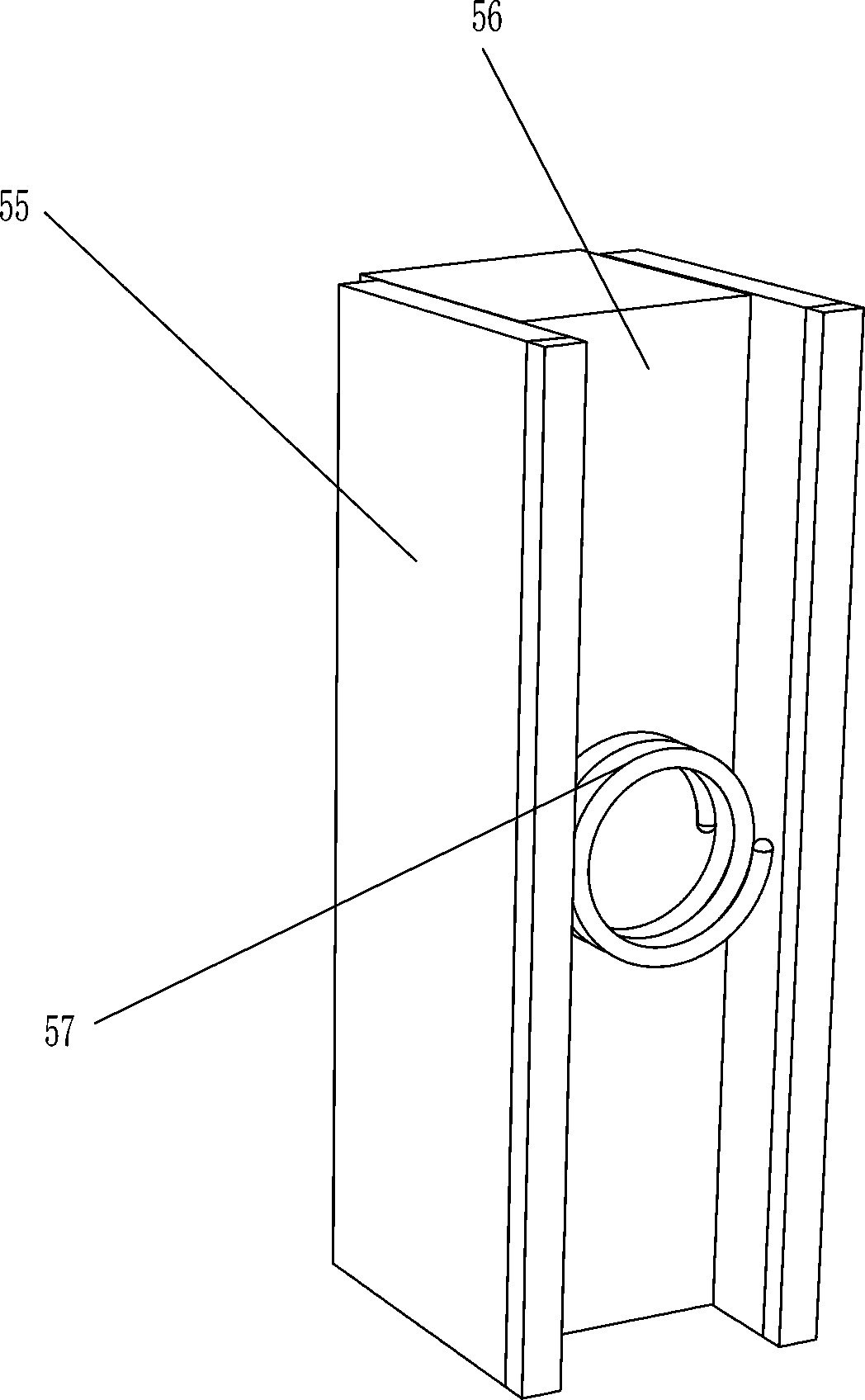

[0033] On the basis of Example 1, such as Figure 7 and Figure 8 As shown, a fixed assembly 5 is also included, and the fixed assembly 5 includes a snap ring 51, a swing arm 53, a shift block 54, a slide seat 55, a sliding block 56 and a return spring 57, and the lower part of the outer wall of the joystick 2 is connected with a snap ring 51, the clasp 51 is provided with a card slot 52, the outer wall of the joystick 2 on the lower side of the clasp 51 is hingedly connected with a swing arm 53, the upper part of the swing arm 53 is located in the card slot 52, and the lower part of the swing arm 53 is connected with a dial 54 The lower part of the inner wall of the hollow tube 1 is connected with a sliding seat 55, and the sliding block 56 is slidably connected in the sliding seat 55. The sliding block 56 cooperates with the swing arm 53, and the sliding seat 55 is provided with a reset spring 57. One end is connected with the sliding block 56 , and the other end of the ret...

Embodiment 3

[0036] On the basis of Example 2, such as Figure 9 As shown, the labor-saving assembly 6 is also included, and the labor-saving assembly 6 includes a sleeve 61, a fixed rod 63, a guide rod 64 and a driving rod 65. The outer surface of the handle 21 is connected with the sleeve 61, and the outer surface of the sleeve 61 is provided with a Chute 62, sliding type is connected with driving rod 65 in the inclined groove 62, and the outer surface of driving rod 65 is connected with guide rod 64, and the top of guide rod 64 is slidably connected with fixed rod 63, and the left side of fixed rod 63 and hollow tube 1 in contact with the outer wall.

[0037] The picker moves the fixed rod 63 upwards, and the driving rod 65 can be moved upwards through the chute 62 by the guide rod 64, and the upward movement of the driving rod 65 through the chute 62 can make the sleeve pipe 61 rotate counterclockwise, and the sleeve pipe 61 rotates counterclockwise through the handle 21 drives joysti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com