Platform type automatic spot welding machine

An automatic point, platform type technology, applied in welding equipment, resistance welding equipment, resistance electrode bases, etc., can solve the problems of uneven product quality, workpiece offset, etc., to improve quality, avoid shaking, and avoid inconsistent welding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

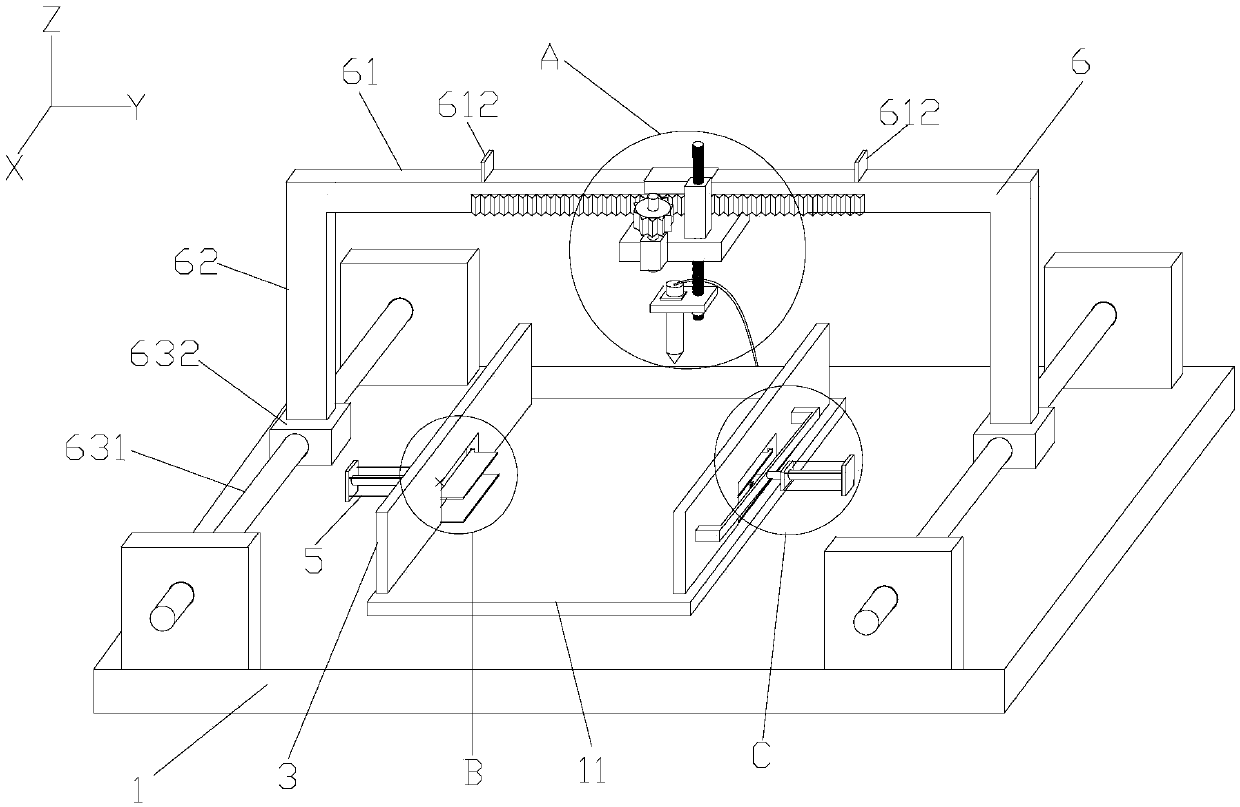

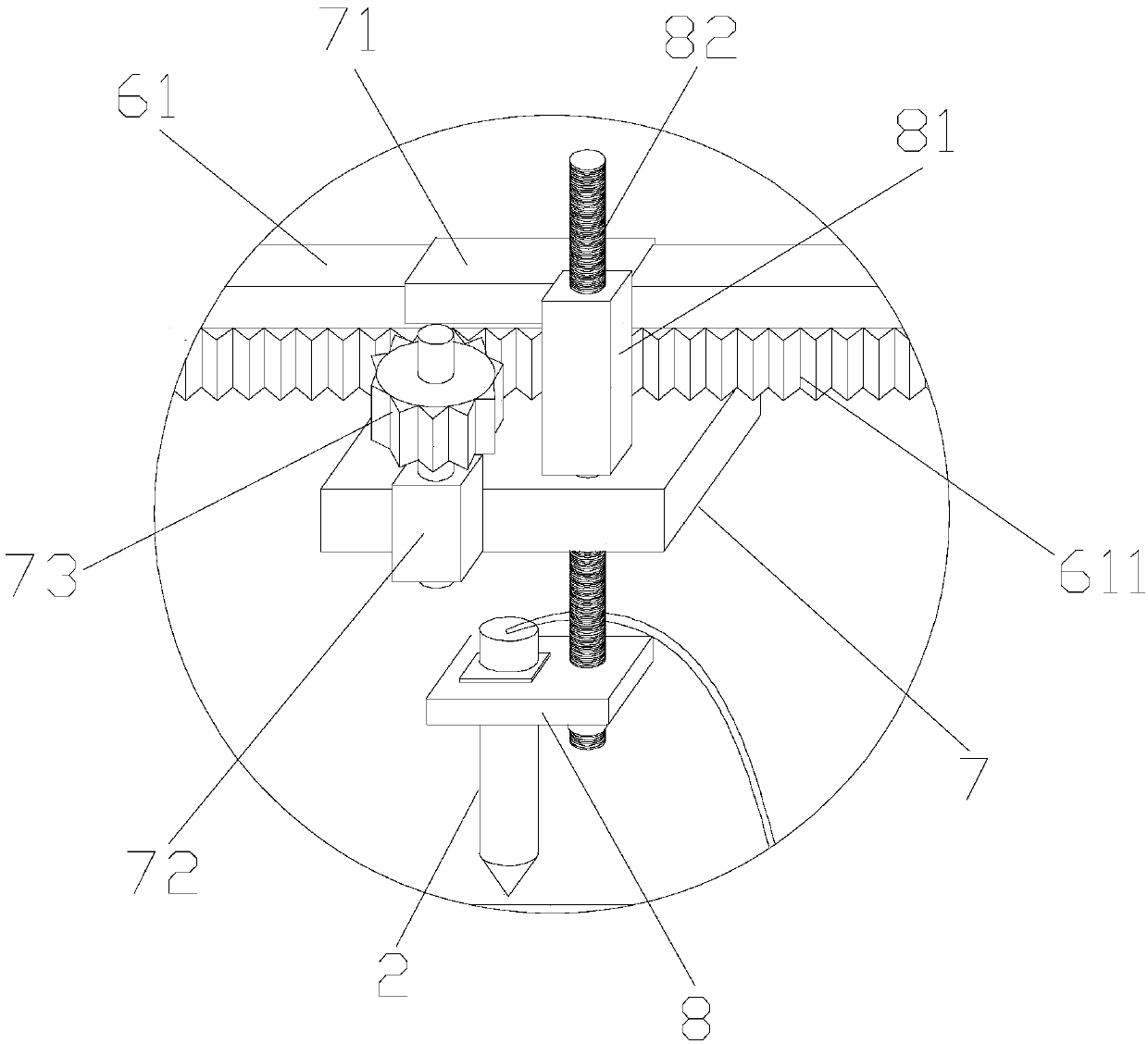

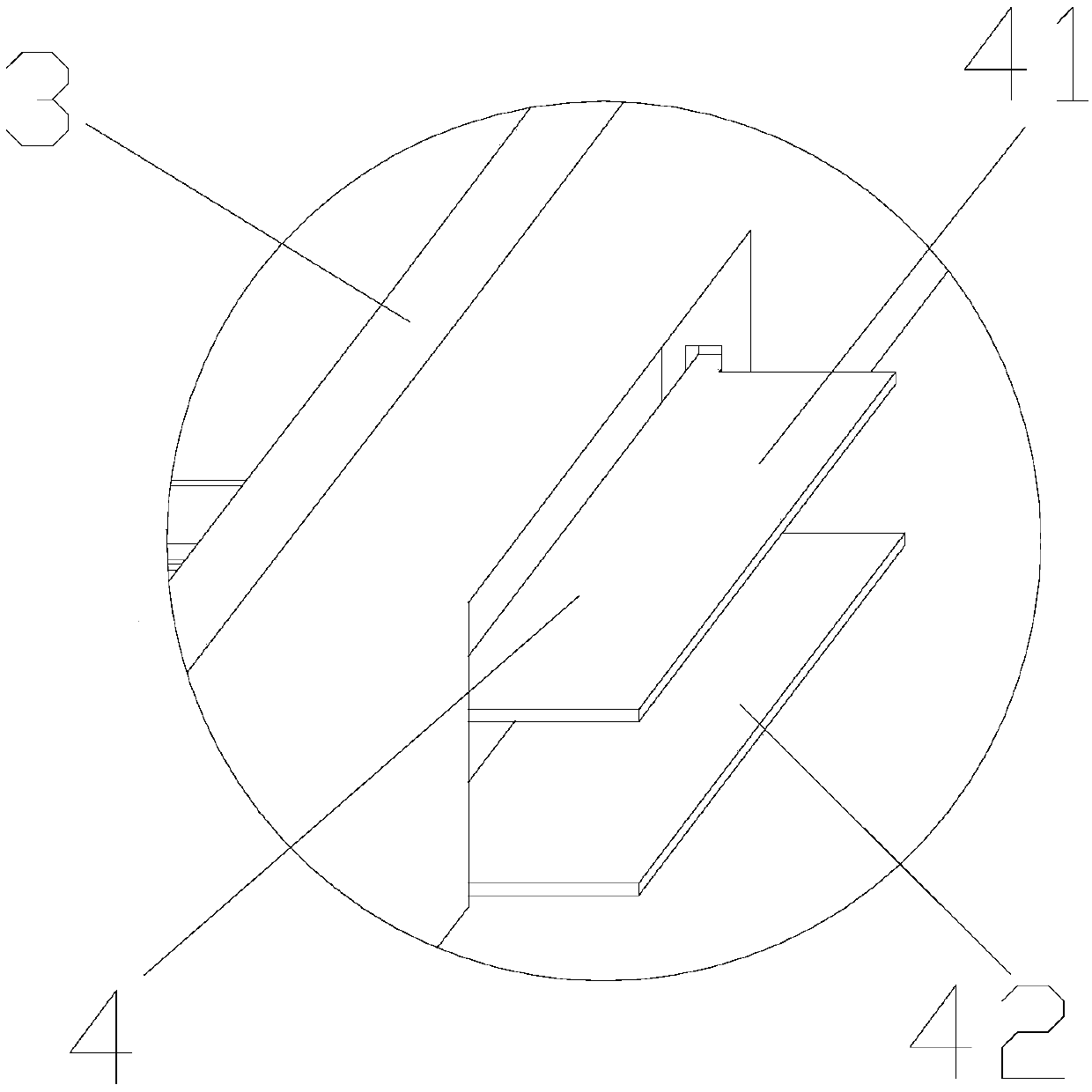

[0022] See attached Figure 1-4 As shown, a platform-type automatic spot welding machine of the present invention includes a worktable 1, on which a backing plate 11 for placing workpieces is fixedly connected, and the outer side of the backing plate 11 is provided with a welding torch 2 to move The mobile device, the welding torch 2 is fixed on the mobile device and is located above the backing plate 11. The backing plate 11 is symmetrically provided with limiting devices located on both sides of the workpiece and capable of moving along the backing plate 11 . The limiting device includes a side plate 3 that can move along the backing plate 11. The side plate 3 close to the workpiece is provided with a pressing assembly 4 for fixing the workpiece, and the other side is provided with a pressing assembly 4 for driving the side plate 3 to move. Cylinder assembly 5.

[0023] The middle part of the lower end of the side plate 3 is provided with a left and right through groove, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com