An automobile anti-collision beam processing device

A processing device and anti-collision beam technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of drilling debris falling on the work surface, the working environment, and the difficulty of cleaning, etc. The effect of fixing the strength and reducing the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

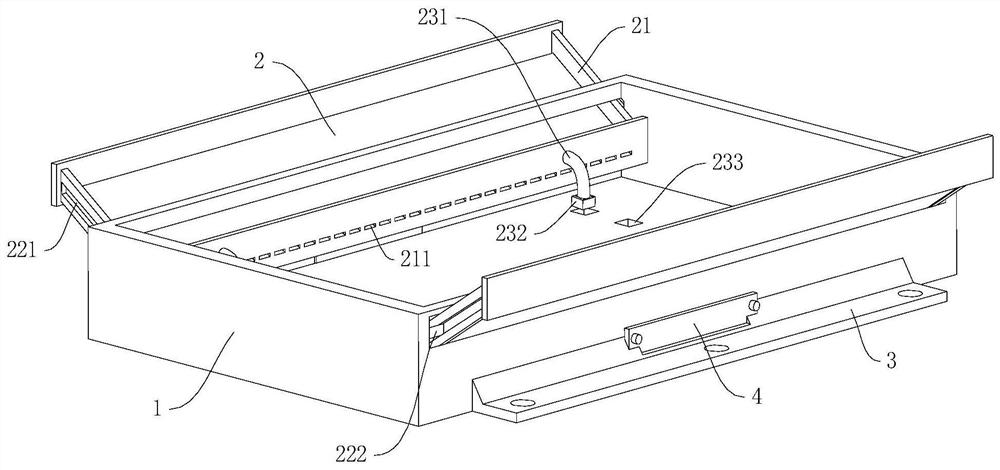

[0022] Including the bottom capacity cartridge 1 of the waste accommodating the waste generated by the automobile anti-collision beam process, the inside of the bottom capacity cartridge 1 is fixed to the ground, and the side surface of the undercarriage 1 is mounted. The projection of the protective surface of the plate 2 and the outer guard plate 2 and the bottom capacity cartridge 1 cover the entire vehicle anti-collision beam processing device, and the outer guard 2 is covered with a blade 21, the outer cutting plate of the inner cavity depth. 2 The blade 21 is established to be installed and surrounded by the outside of the outer guard 2.

[0023] When machining the car anti-collision beam is machined, the bottomroom cassette 1 is mounted in advance, and the cooling water or slag generated during the processing process is concentrated, and it is concentrated in the lumen of the bottom chamber 1. The guard 2 can effectively splash the slope, cooling water protection during the...

Embodiment 2

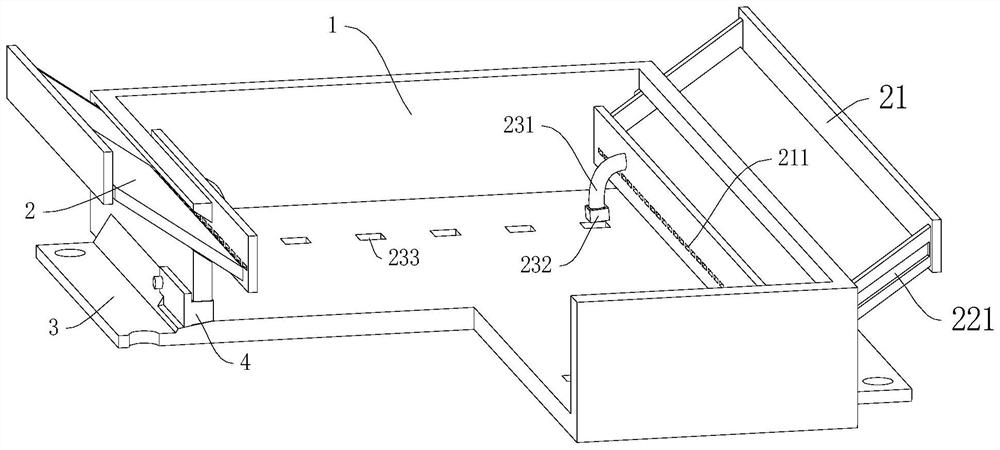

[0025] The difference from the first embodiment is that the protection range composed of the outer guard 2 and the bottom chamber 1 adapts to the protection of different sizes of car anti-collision beam processing devices:

[0026] The slot 221 is opened on the plate 21 on the left and right sides of the outer cutting plate 2, and the chute 221 is slidably provided with a guide 222 connected to the bottom chamber 1, and the outer guard 2 and the bottom chamber 1 are relatively sliding, and A connecting pipe 231, a block 232, and a card slot 233 relatively fixed, and the tube 231 are connected to the outer guard plate 2 or the casing 22, and the cylinder 232 is connected to the outer guard 2 or the casing 23. One end of the tube 231 is fixed in the card slot 233;

[0027] The card slot 233 is a plurality of cavities that are allocated in the bottom chamber 1, and the inner pipe 231 is connected to the outer blade 2 adjacent to the side of the bottom-capacity box 1, and the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com