A uv_led drying device for printing presses

A drying device and printing machine technology, applied to general parts of printing machinery, printing machines, printing, etc., can solve problems such as waste of resources, achieve the effects of reducing system cost, reducing quantity, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

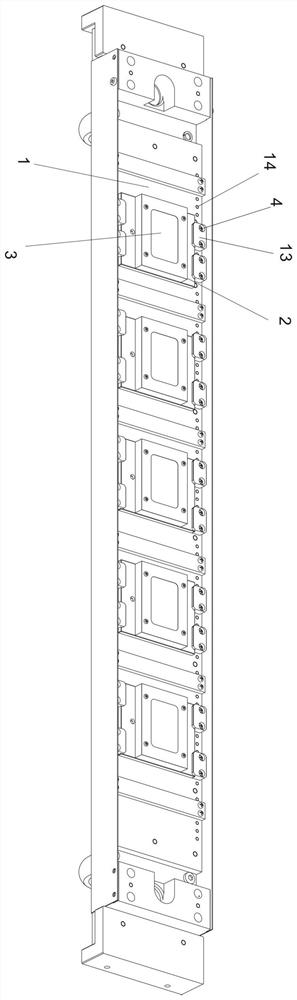

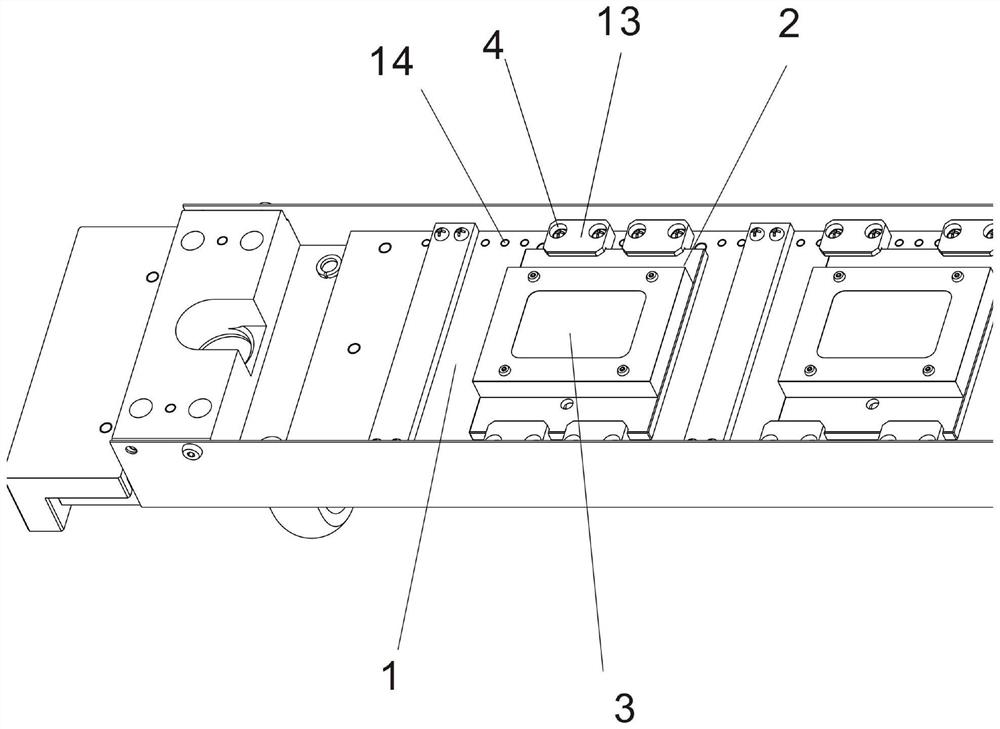

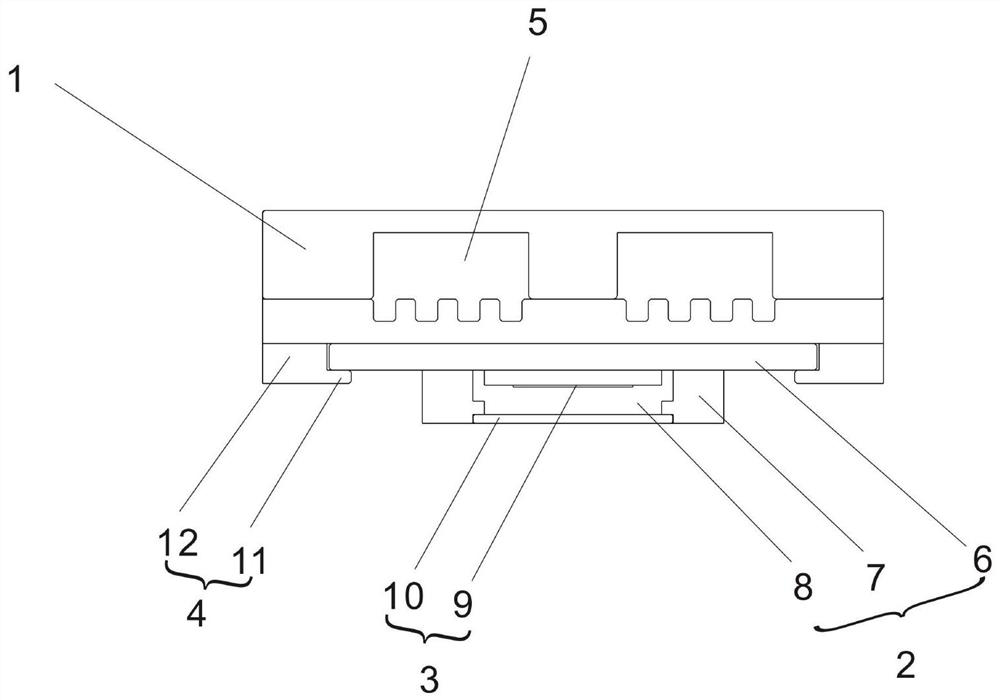

[0057] like Figures 1 to 2 As shown, a UV_LED drying device for a printing machine includes a cooling base plate 1, a bracket assembly 2, a UV_LED light-emitting module 3, a bracket position adjustment assembly 4 and an electrical control assembly; a bracket assembly 2 is installed on the cooling base plate 1; the bracket assembly 2 The UV_LED light emitting module 3 is installed on the top; the bracket position adjustment component 4 is used to adjust the position between the bracket component 2 and the cooling base plate 1 ; the electrical control component is used to control the UV_LED light emitting module 3 .

[0058] The present invention discloses a UV_LED drying device for a printing machine, wherein the position between the bracket assembly 2 and the cooling base plate 1 can be adjusted through the support position adjustment assembly 4, so that the distribution of the UV_LED light-emitting modules 3 on the cooling base plate 1 can be adjusted In addition, the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com