Torque transmission flange structure and components and parts with flange structure

A technology of torque transmission and flange, which is applied in the field of torque transmission flange structure and parts with this flange structure, and can solve the problems of difficult processing of precision keys and keyways, high processing requirements, troublesome assembly and disassembly, etc. , to achieve the effect of improving transmission accuracy, improving torsion capacity and avoiding inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

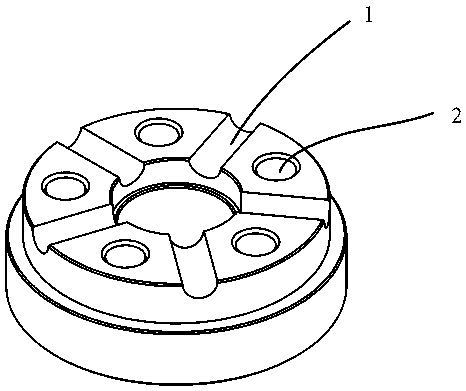

[0025] Example 1, such as figure 1 As shown, a flange has 5 threaded holes and 5 semi-cylindrical grooves processed on the end face. In this embodiment, the axis line of the semi-cylindrical groove is processed on the radius line of the flange end face. It is perpendicular to and intersects with the central axis of the flange. The semi-cylindrical groove is milled by a ball milling cutter along the radius line of the flange end face. Since more than three bolts are used for fixing and more than three semi-cylindrical grooves The grooves are more conducive to the structural stability after the flange connection, so this embodiment selects 5 threaded holes and 5 semi-cylindrical grooves with open ends. In order to ensure the parallelism after the flange connection, the processed 5 The size of the two semi-cylindrical grooves needs to be the same or ensure a small processing tolerance, so that when connecting with another flange, putting 5 pins with the same outer diameter can en...

Embodiment 2

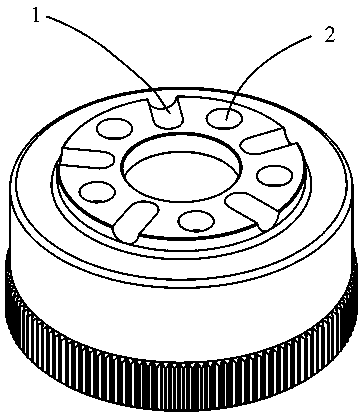

[0026] Example 2, such as figure 2 As shown, a harmonic reducer flexspline with the torque transmission flange structure of the present invention, the flexspline of the harmonic reducer uses the flexspline material of the prior art and the existing processing technology to process the flanging thin-walled structure and teeth , on the flange structure of the flanging surface of the flexible spline, there are 5 through holes for bolts and 5 semi-cylindrical grooves with half-rounded corners and half-open sides. The semi-cylindrical grooves are along the The radius line milling of the flange end face of the flexspline flanging is made.

Embodiment 3

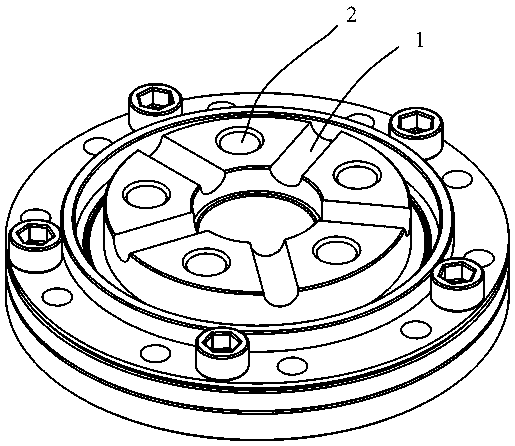

[0027] Example 3, such as image 3 As shown, it is specifically a crossed roller bearing whose inner ring flange structure is the torque transmission flange structure of the present invention. The inner ring, outer ring and rollers of the bearing are made by the prior art. Between the 5 threaded holes of the flange, use a ball milling cutter to mill along the radius line of the flange end face of the flexspline flanging to make 5 semi-cylindrical grooves with open ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com