Separating device

A separation device, cylindrical technology, applied in blasting, mining equipment, earth-moving drilling, etc., can solve the problems of difficult operation, long construction period, scattered rock force, etc., and achieve the effect of convenient transportation and feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

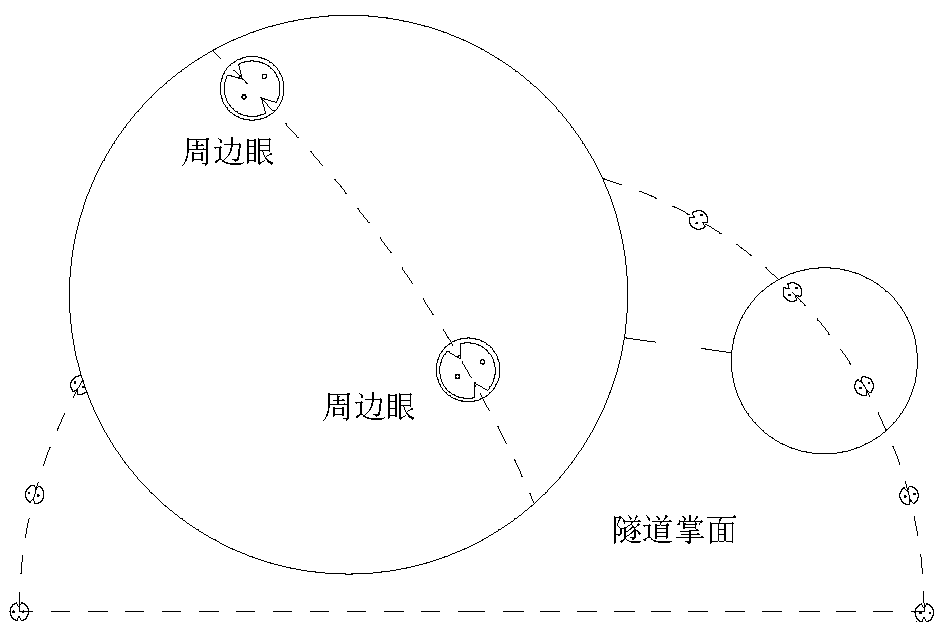

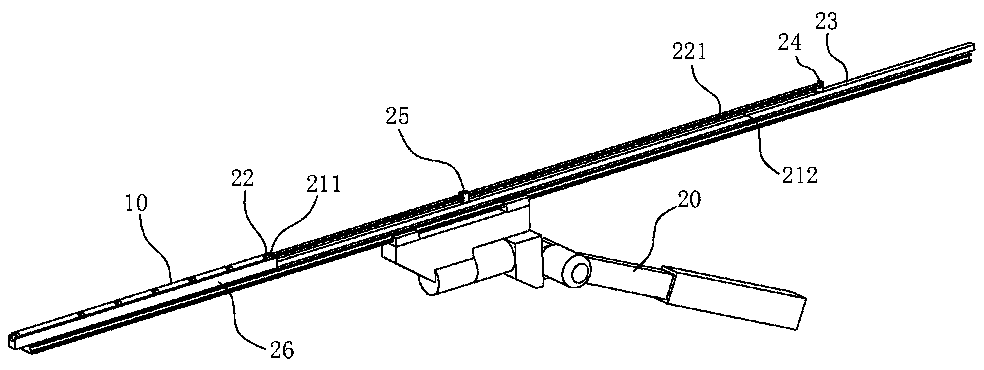

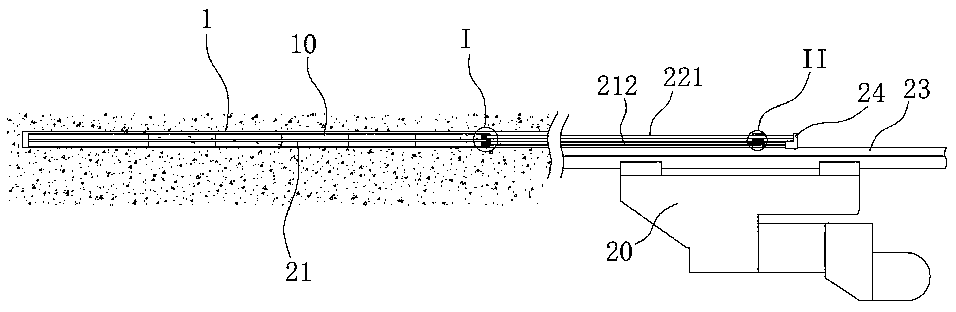

[0036] Such as figure 2 , 3 , 6, a palm blasting explosives layout system, the explosives include at least two cylindrical shells 10 coaxially arranged, such as Figure 9 , 10 , 11, two V-shaped energy-gathering grooves 11 sunk toward the center of the cylindrical shell 10 are symmetrically arranged on the peripheral surface of the cylindrical shell 10, and the length direction of the V-shaped energy-gathering grooves 11 is in line with the cylinder The axial direction of the cylindrical shell 10 is parallel; the emulsion explosive is filled in the cylindrical shell 10; as Figure 12 , 13, 14, the two ends of the cylindrical housing 10 are respectively provided with a first end seat 12 and a second end seat 13, and the first end seat 12 and the second end seat 13 are provided with a V-shaped poly A V-shaped groove connected to the energy groove 11, a positioning device is provided on the first end seat 12; the positioning device includes a positioning block 121 that is te...

Embodiment 2

[0047] A method for filling explosives by palm surface blasting using the system described in Embodiment 1, comprising the steps of:

[0048] Step 1: Butt the multi-stage explosives into a whole, and insert the V-shaped energy-gathering groove 11 on the two guide rods 21;

[0049] Step 2: Use the rotary drive unit to adjust the direction of the V-shaped energy-gathering groove 11 of the explosive, so that the two V-shaped energy-gathering grooves 11 are respectively facing two adjacent blastholes on both sides of the blasthole to be loaded;

[0050] Step 3: Use the drive mechanism to push the explosives as a whole to the inner end of the blast hole;

[0051] Step 4: The driving mechanism drives the guide rod 21 to be continuously pulled out of the blasthole, and at the same time drives the block seat 22 to be pulled out of the blast hole intermittently. The V-shaped energy-gathering groove 11 is pulled away, and then the explosive positioning device at the innermost end is ej...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com