Ultrasonic detection device for automobile maintenance

A detection device, ultrasonic technology, applied in the direction of measuring device, using ultrasonic/sonic wave/infrasonic wave, mechanical measuring device, etc., can solve the problems of engine damage, time-consuming and laborious, low measurement accuracy and detection efficiency, etc., to reduce gas leakage and improve The effect of stability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

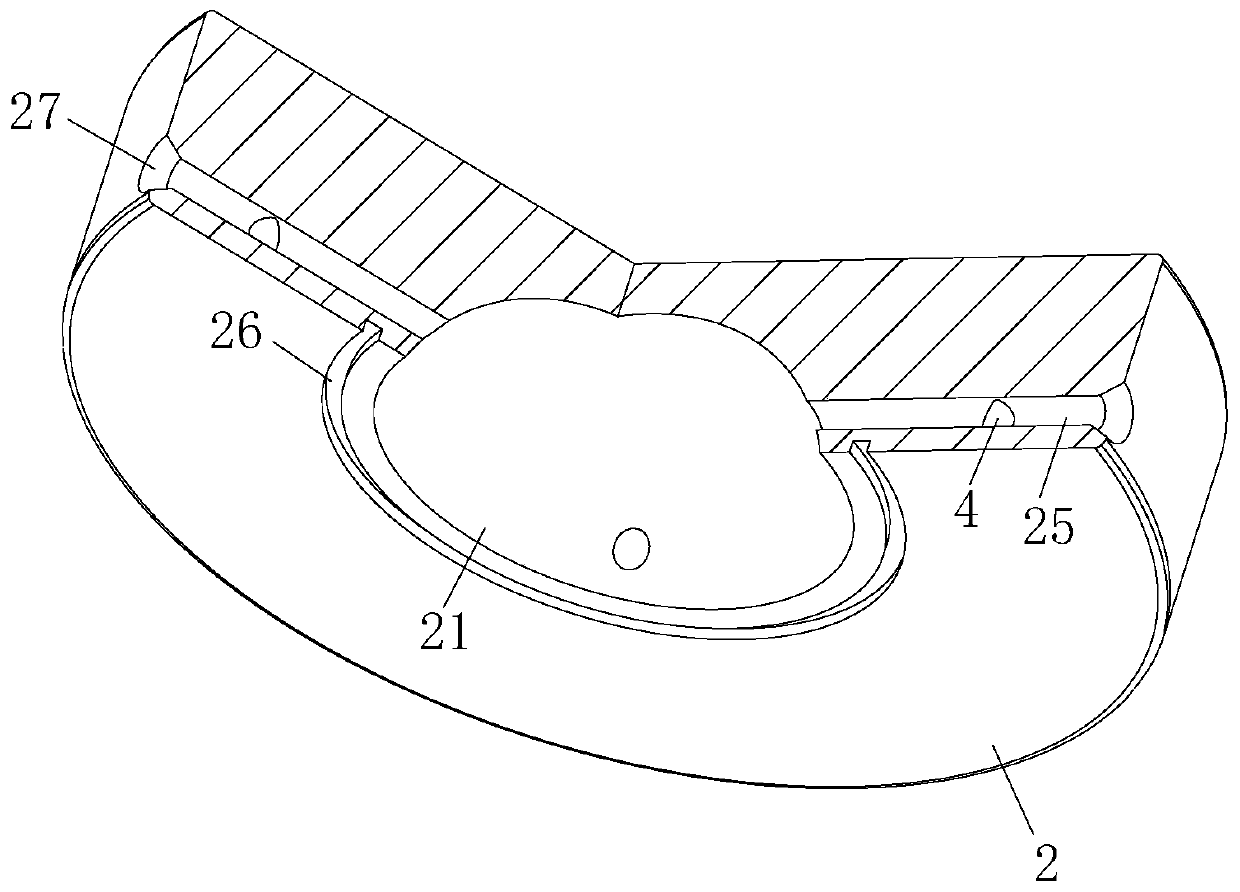

[0027] As an embodiment of the present invention, the set number of the driving grooves 23 is at least three groups, and the driving grooves 23 are uniformly arranged on the outer surface of the driving ball 22 in a ring; when working, when only one group is set When driving the groove 23, it is necessary to rotate the rotating disk 2 outside the driving groove 23 for a week to make it drive the air pipe 25 to clean the entire annular cylinder inner wall, and the cleaning effect is not good enough. At this time, by setting the number of driving grooves 23 And the distribution form, so that the drive slots 23 and the ventilation pipes 25 with an increased number of groups can quickly and efficiently clean the impurities on the inner wall of the cylinder, thereby effectively improving the cleaning quality of the cylinder by the ultrasonic detection device.

[0028] As an embodiment of the present invention, the outer end of the air pipe 25 is provided with a transition groove 27 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com