Coarse particle escape prevention device for horizontal centrifuge

A horizontal centrifuge, anti-running technology, applied to centrifuges, centrifuges with rotating drums, etc., can solve the problems of deterioration, burden, and roughness of the slime water system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

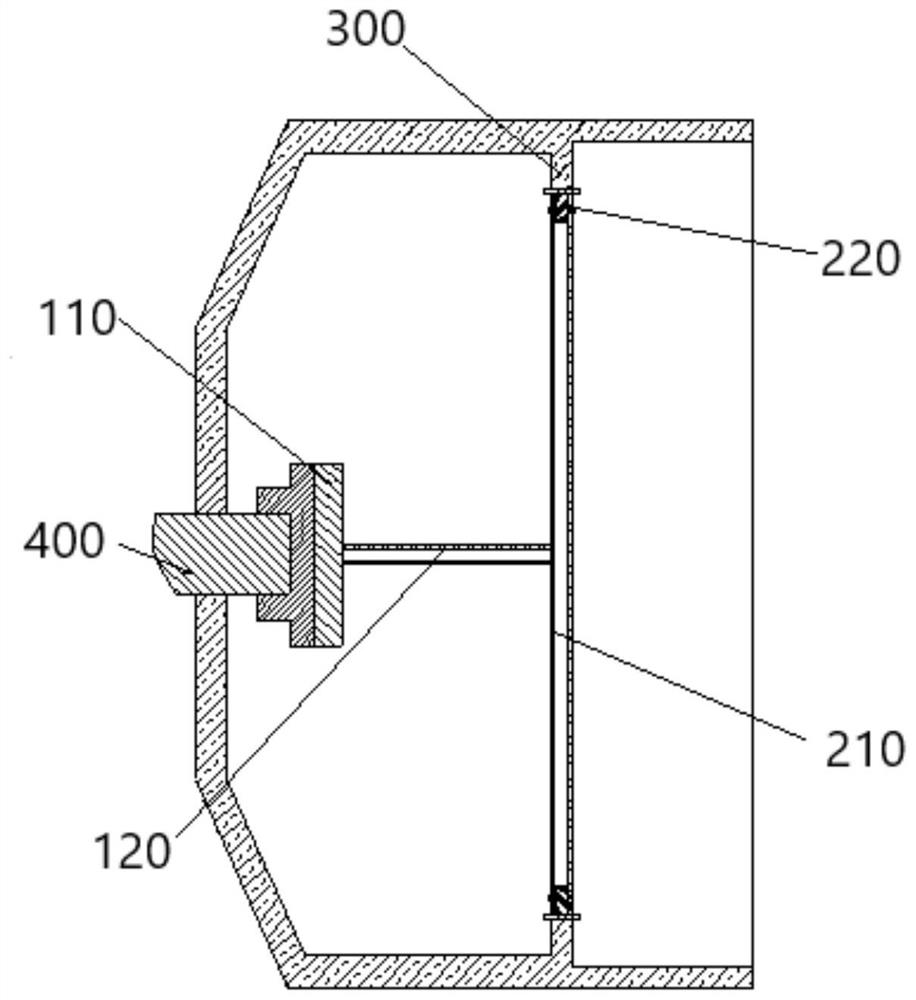

[0023] Such as figure 1 , figure 2 Shown is a horizontal centrifuge anti-run rough device provided by the present invention, which includes a connecting part used to connect with the horizontal centrifuge and rotate with the main shaft 400, and a smearing part connected to the connecting part, and the smearing part passes through With the rotation of the main shaft 400 of the horizontal centrifuge, the wear-resistant granular glue is applied to the smearing surface of the boss 300 of the horizontal centrifuge to realize the anti-running of the horizontal centrifuge.

[0024] Specifically, the smearing part includes a rotating rod 210 connected to the connecting part, a squeegee 220 arranged on the end of the rotating rod 210 for applying glue to the smearing surface, and the squeegee 220 is arranged at least on the rotating rod 210 at one end.

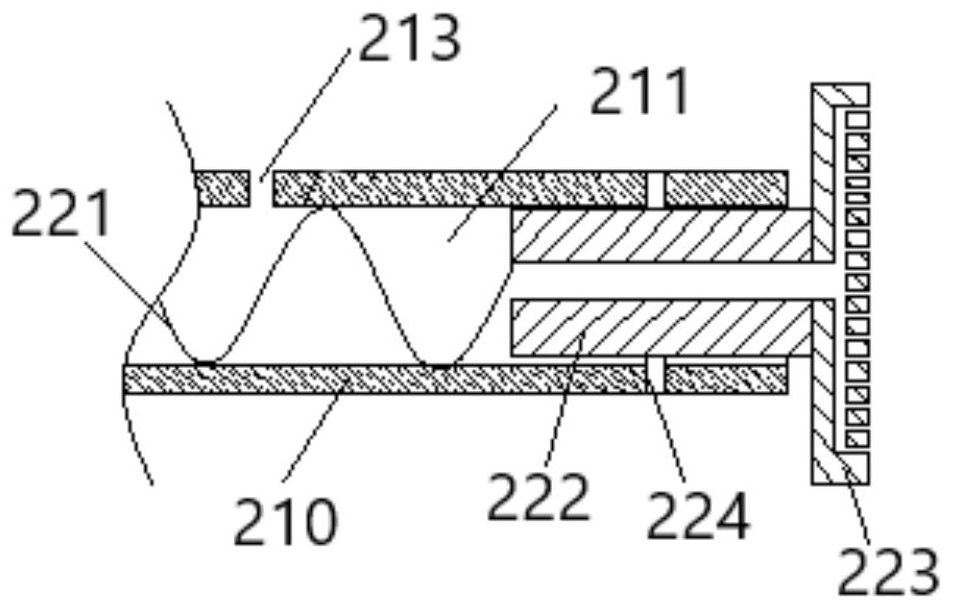

[0025] Specifically, the connecting end of the rotating rod 210 and the squeegee 220 is provided with an accommodating space 211 f...

Embodiment 2

[0041] The part of this solution that is the same as that of Embodiment 1 will not be described in detail. The rotating rod 210 is not provided with an accommodating space 211 for accommodating the glue injection hole. It is connected to the main shaft 400 of the horizontal centrifuge by bolts, and then the extension rod 120 and the rotating rod 210 are extended to the corresponding scale according to the model of the horizontal centrifuge. When the horizontal centrifuge to be maintained has no corresponding scale, the extension The extended length of the long rod 120 is the distance from the outer edge of the fixed plate 110 to the inner side of the screen basket mouth. The extended length of the rotating rod 210 is adjusted according to the diameter of the edge of the unworn horizontal centrifuge boss 300, and then the wear-resistant granular glue is applied to the horizontal centrifuge. On the edge of the boss 300 of the horizontal centrifuge, when the main shaft 400 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com