Optical sensor internal orientation element calibration method based on linear array push-broom

An internal orientation element, optical sensor technology, applied in the aerospace field, can solve the problems of data waste, high-precision control data dependence, neglect and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

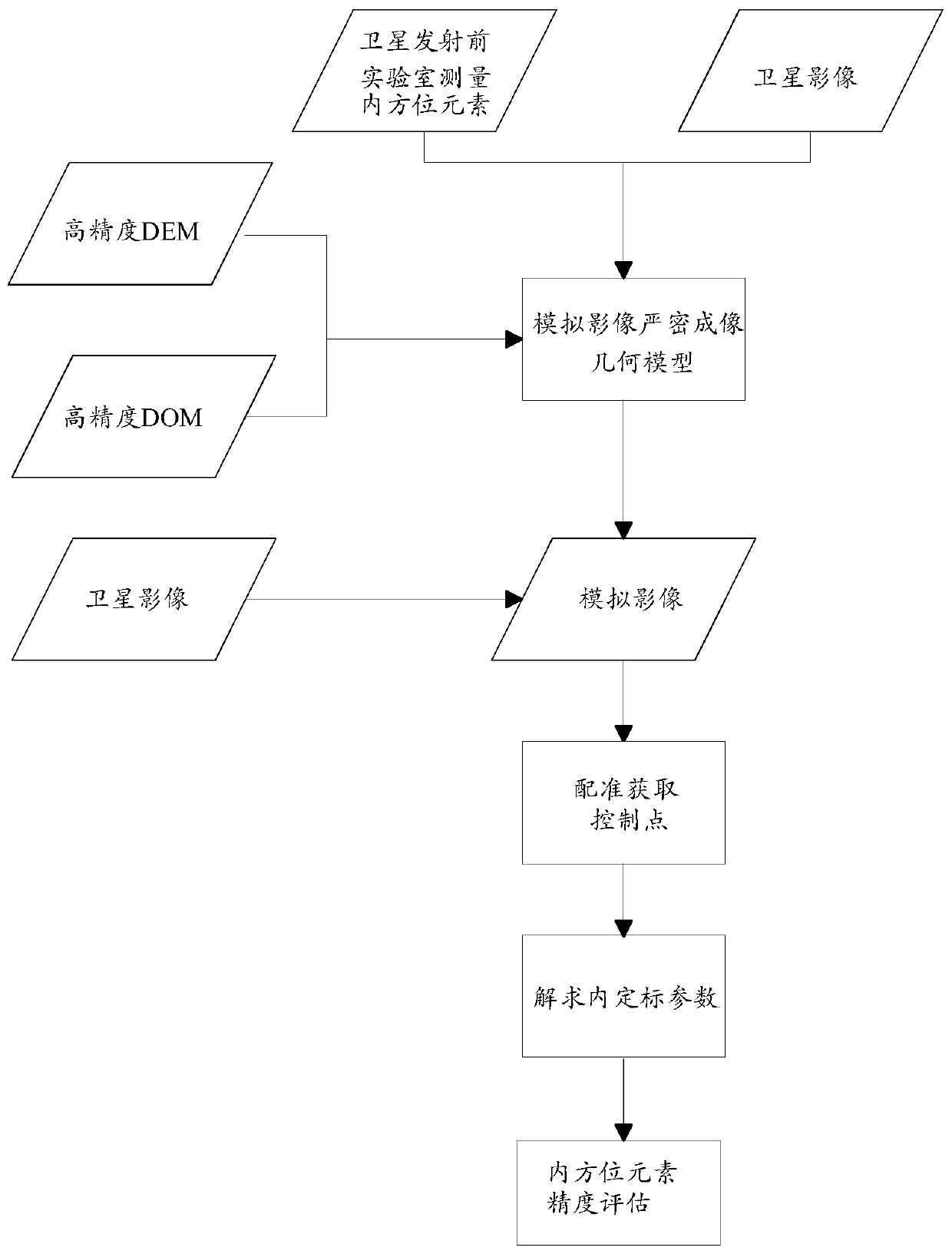

AI Technical Summary

Problems solved by technology

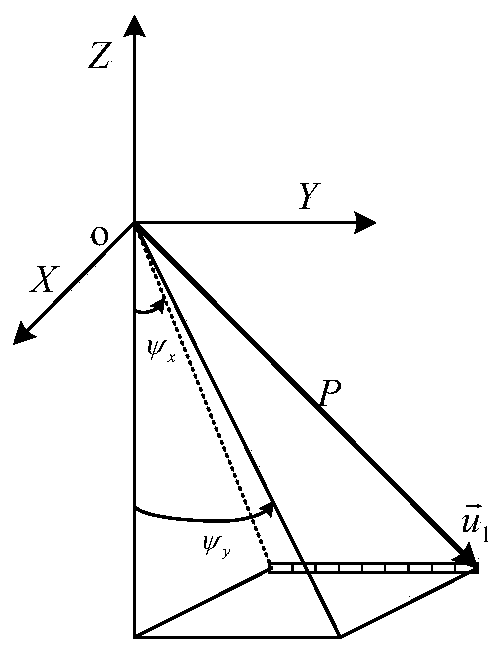

Method used

Image

Examples

Embodiment Construction

[0094] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

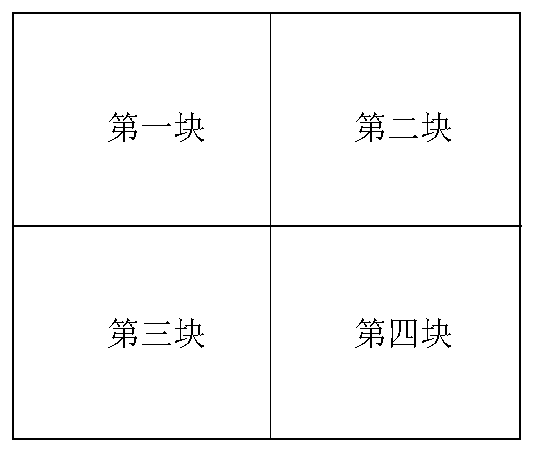

[0095] The data collected in the experiment of this embodiment are as follows: In order to verify the correctness of the geometric cross-checking method, 1:2000 digital orthophotos and digital elevation models covering the Songshan area and Tianjin area in Henan, my country were collected as checking control data. Among them, the coverage area of Tianjin area is about 100km (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com