Secondary gear box fault intelligent diagnosis method based on feature vector baseline method

A eigenvector and intelligent diagnosis technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as inability to accurately diagnose gearbox faults, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

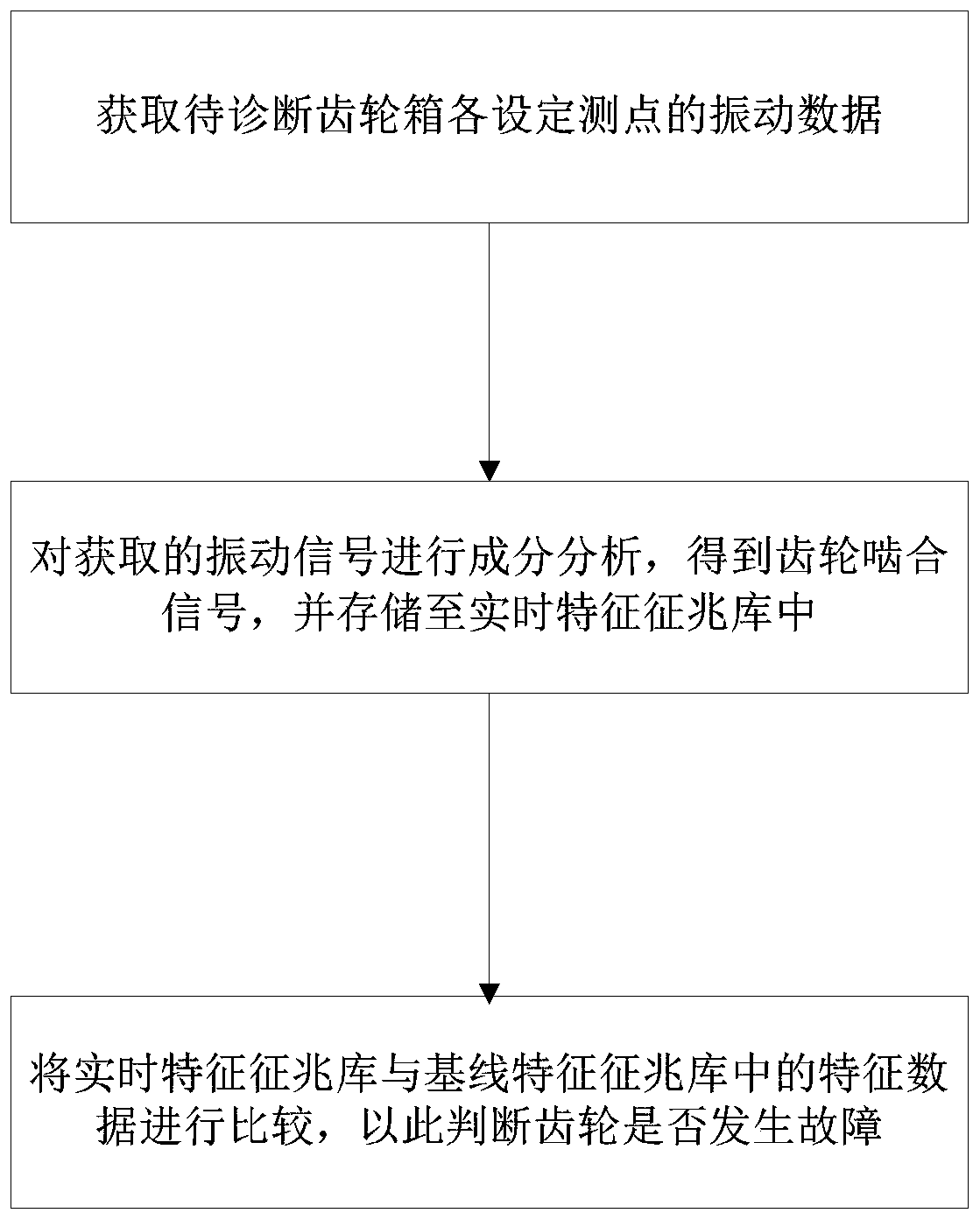

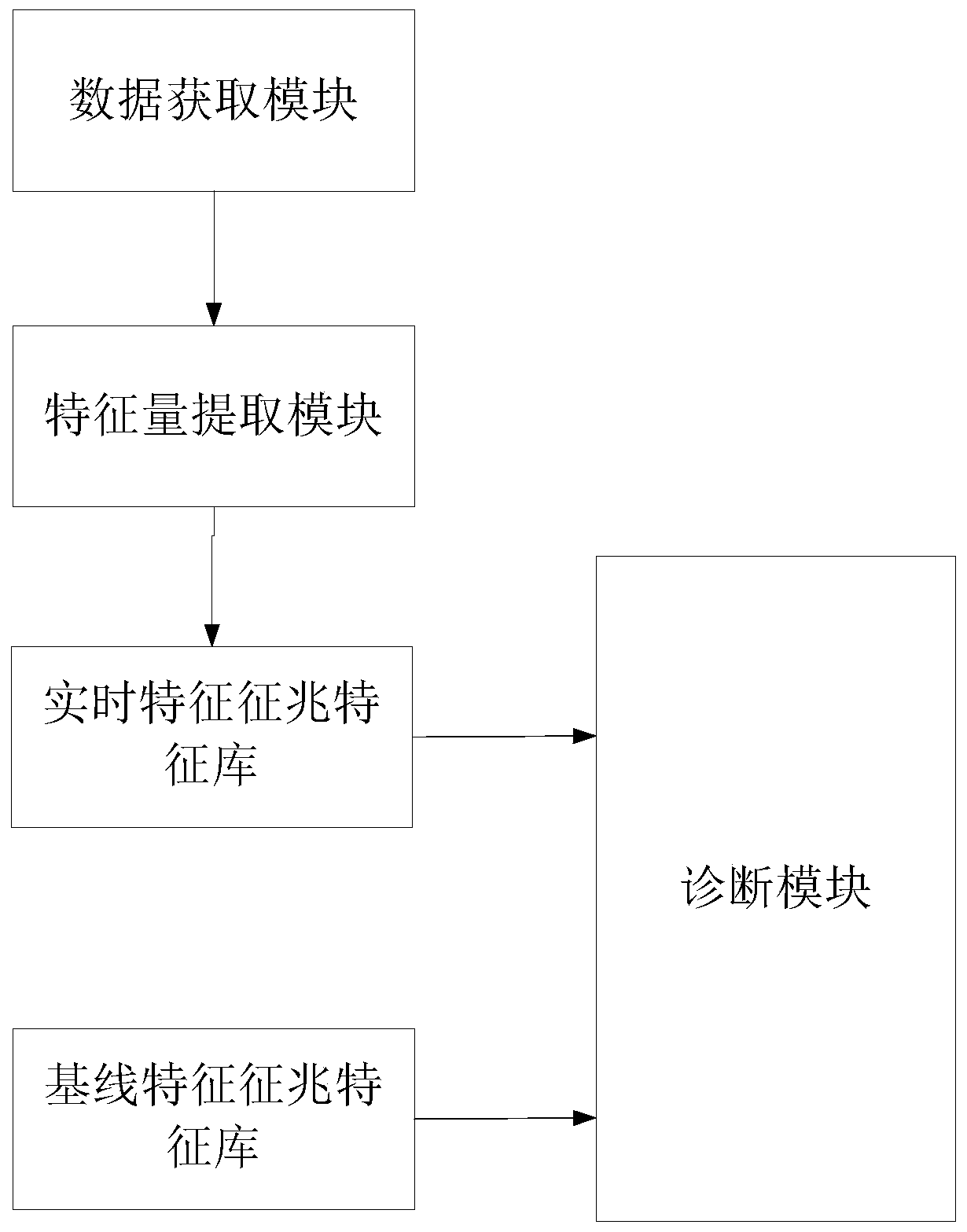

Method used

Image

Examples

example 1

[0066] Example 1: Gear Fault Diagnosis Rules

[0067] if (real-time amplitude of 1 times meshing frequency of high-speed shaft gear - baseline amplitude of 1 times meshing frequency of high-speed shaft gear) / baseline amplitude of 1 times meshing frequency of high-speed shaft gear = 45%;

[0068] or (real-time amplitude of 2 times meshing frequency of high-speed shaft gear - baseline amplitude of 2 times meshing frequency of high-speed shaft gear) / baseline amplitude of 2 times meshing frequency of high-speed shaft gear = 55%;

[0069] or (real-time amplitude of 3 times meshing frequency of high-speed shaft gear - baseline amplitude of 3 times meshing frequency of high-speed shaft gear) / baseline amplitude of 3 times meshing frequency of high-speed shaft gear = 65%;

[0070] then print out "High-speed shaft gear failure, failure degree: serious"

[0071] Table 1 and the above examples only give an implementation mode. The division of the percentage range and the specific d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com