Binding belt structure of snowshoe

A technology for straps and snowshoes, which is applied to snowshoes, shoe uppers, footwear, etc., can solve the problems of unsatisfactory snow-breaking ability of snowshoes, troublesome perforation of straps, and insufficient firmness, etc. Easy to take off shoes and increase the effect of anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

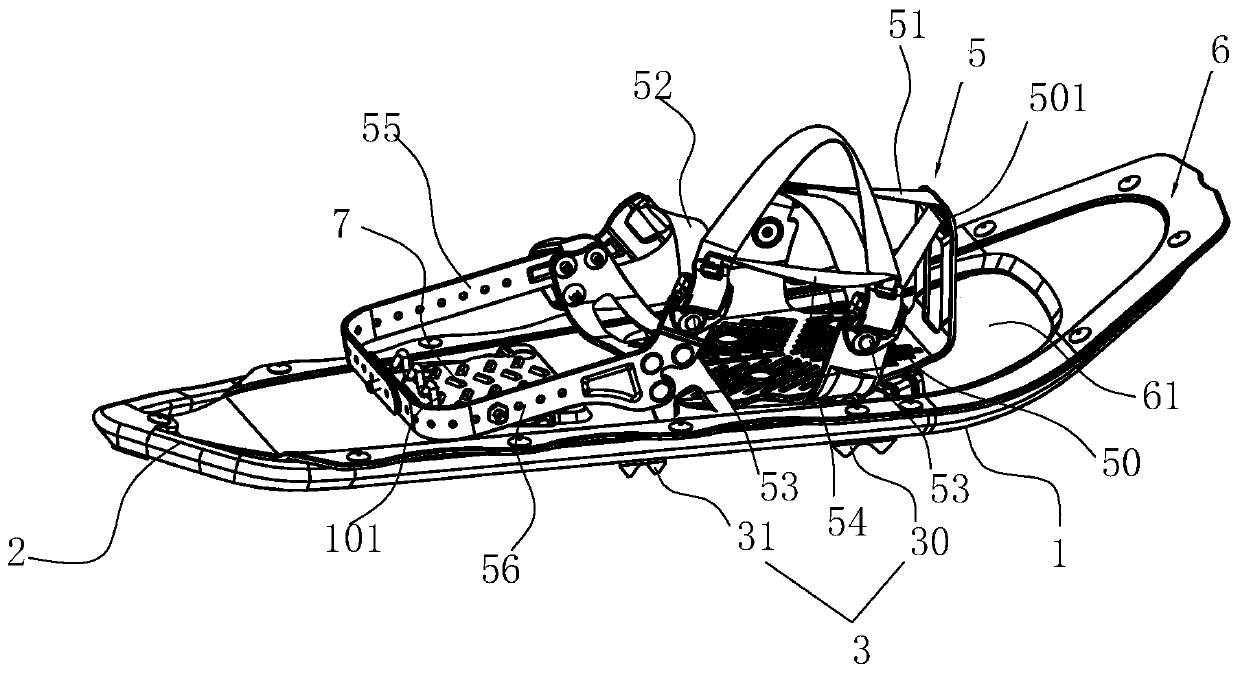

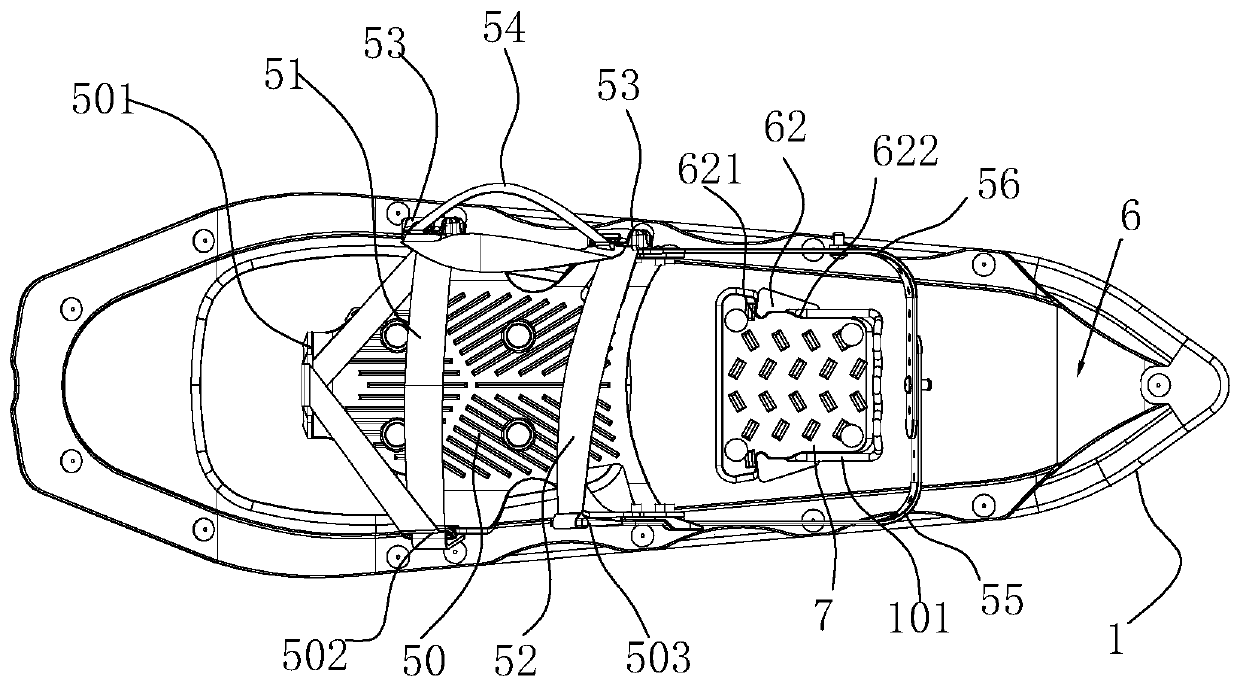

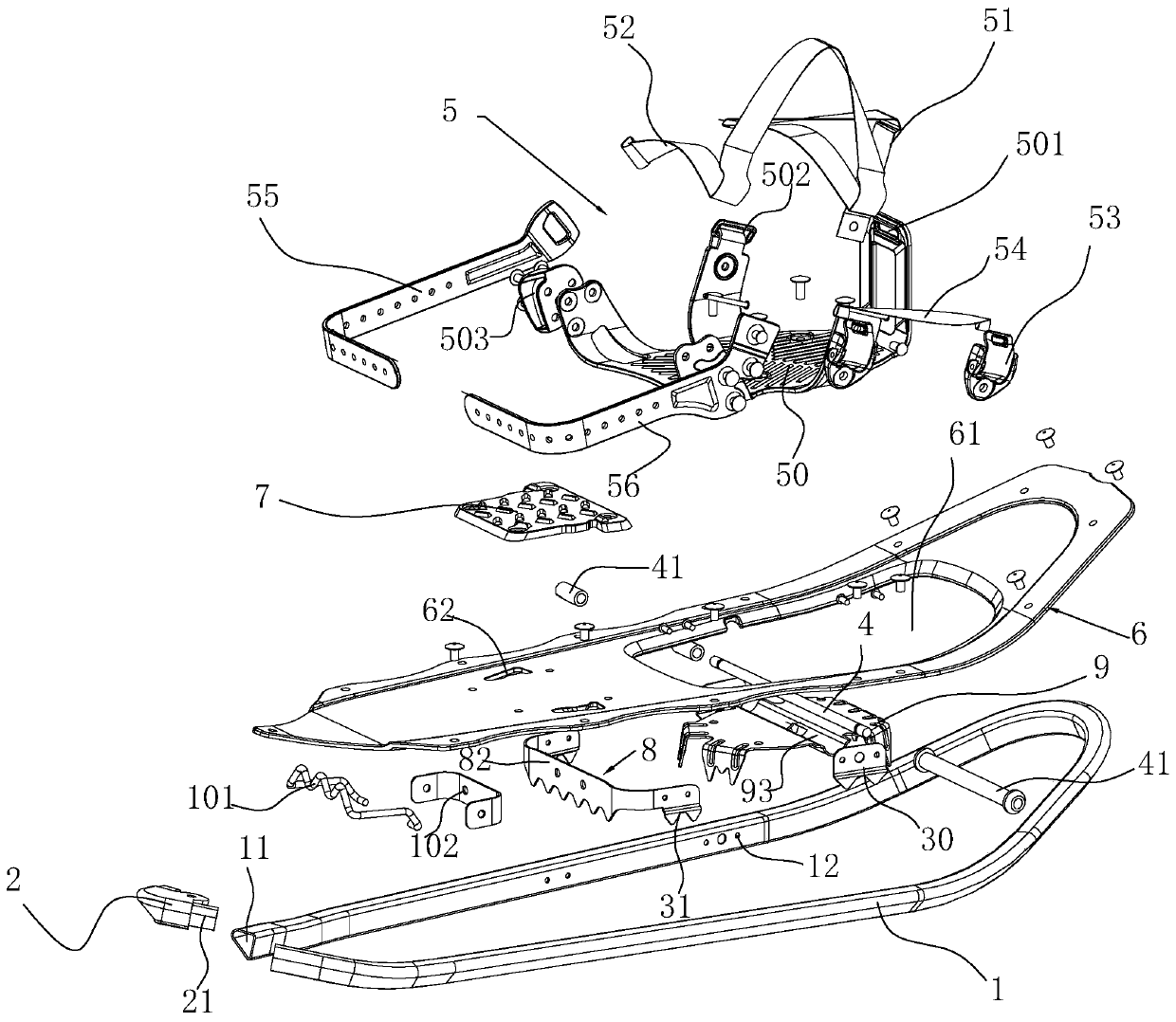

[0045] The snowshoe of the present embodiment mainly comprises four parts of shoe frame 1, vamp 6, shoe tooth and shoe upper 5, and shoe tooth includes side tooth part 3, front tooth part 9 and rear tooth part 8, side tooth part 3, The rear teeth 8 are installed on the shoe frame 1 to form a shoe frame structure, wherein:

[0046] The shoe frame structure includes a shoe frame 1 and a tail connector 2, see Figure 7 , 8 , wherein the shoe frame 1 is a U-shaped structure with a rear opening 11 made of a metal pipe with a triangular cross-section, the middle part is basically horizontal, and both ends are upturned. The metal pipe with a triangular cross-section can be made of aluminum alloy, stainless steel or steel. material, the tail connector 2 is fixedly connected to the rear opening of the shoe frame 1 to form a closed annular shoe frame, the upper end surface of the shoe frame 1 is the mounting surface 13 for the shoe upper 6 to be installed, and the mounting surface 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com