Film framework for oxygen production compressor

A compressor and frame technology, applied in the field of membrane frames for oxygen compressors, can solve the problems of unreasonable support frame structure design, inability to absorb and filter air, and low adsorption and filtration efficiency, so as to reduce the contact range and reduce the cost , Improve the effect of adsorption and filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

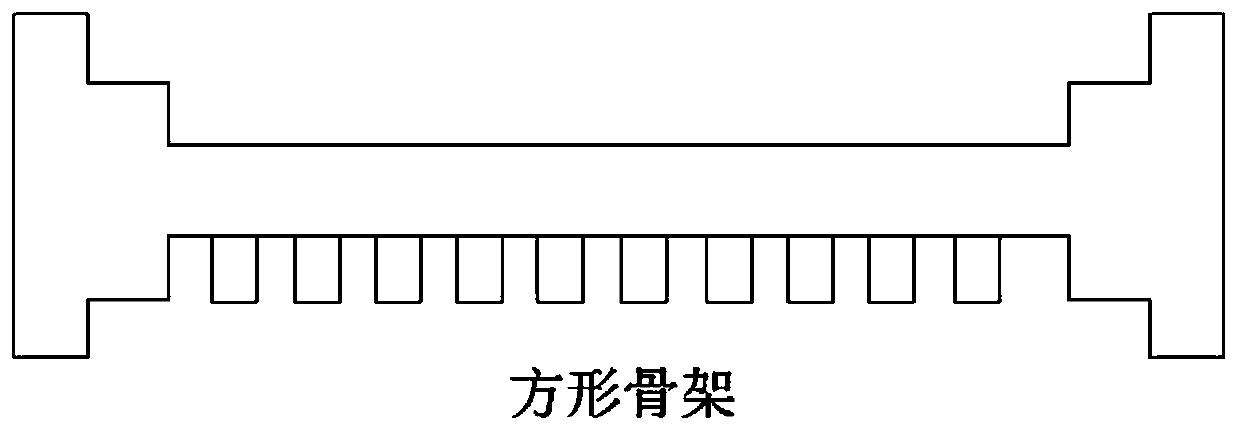

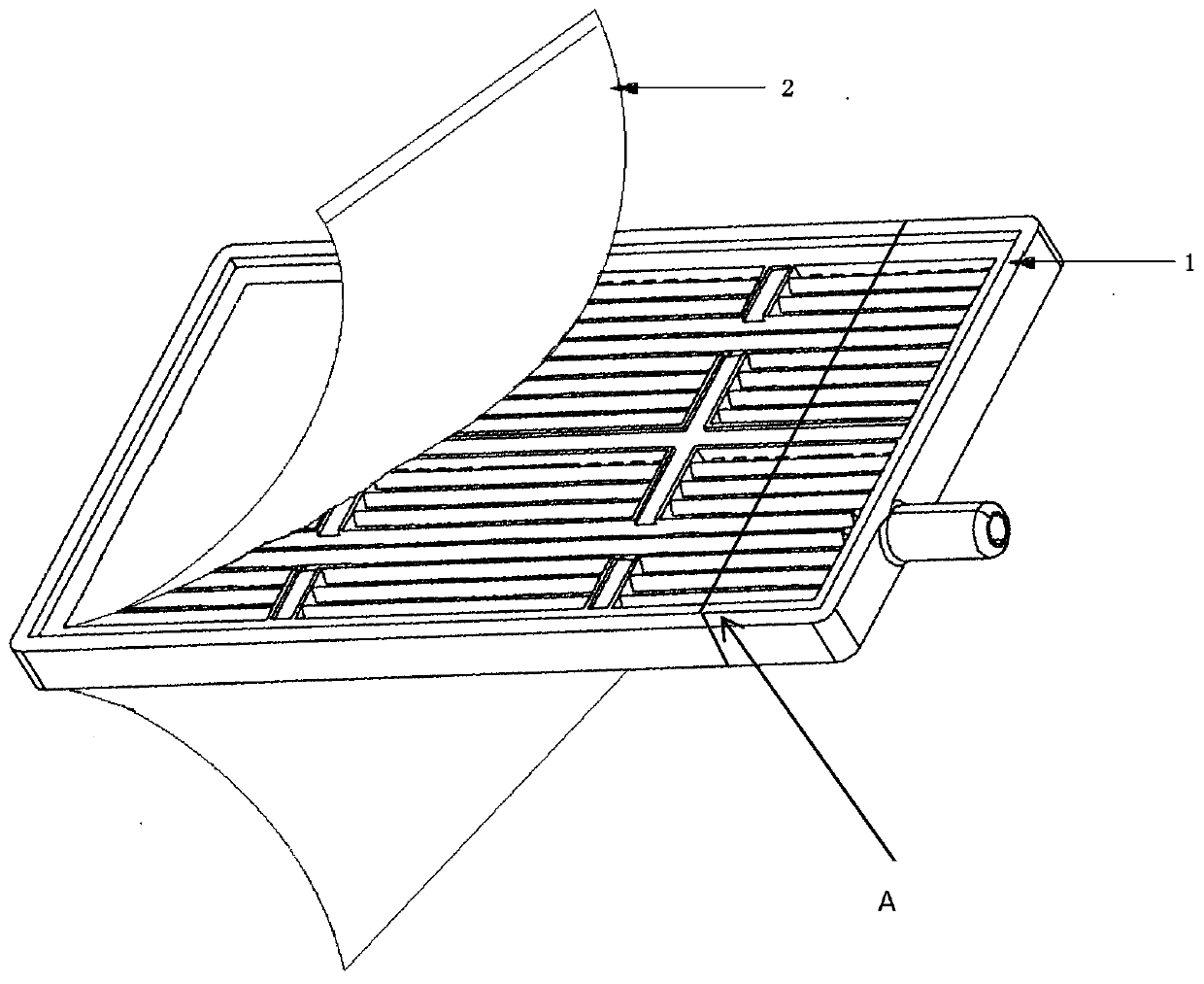

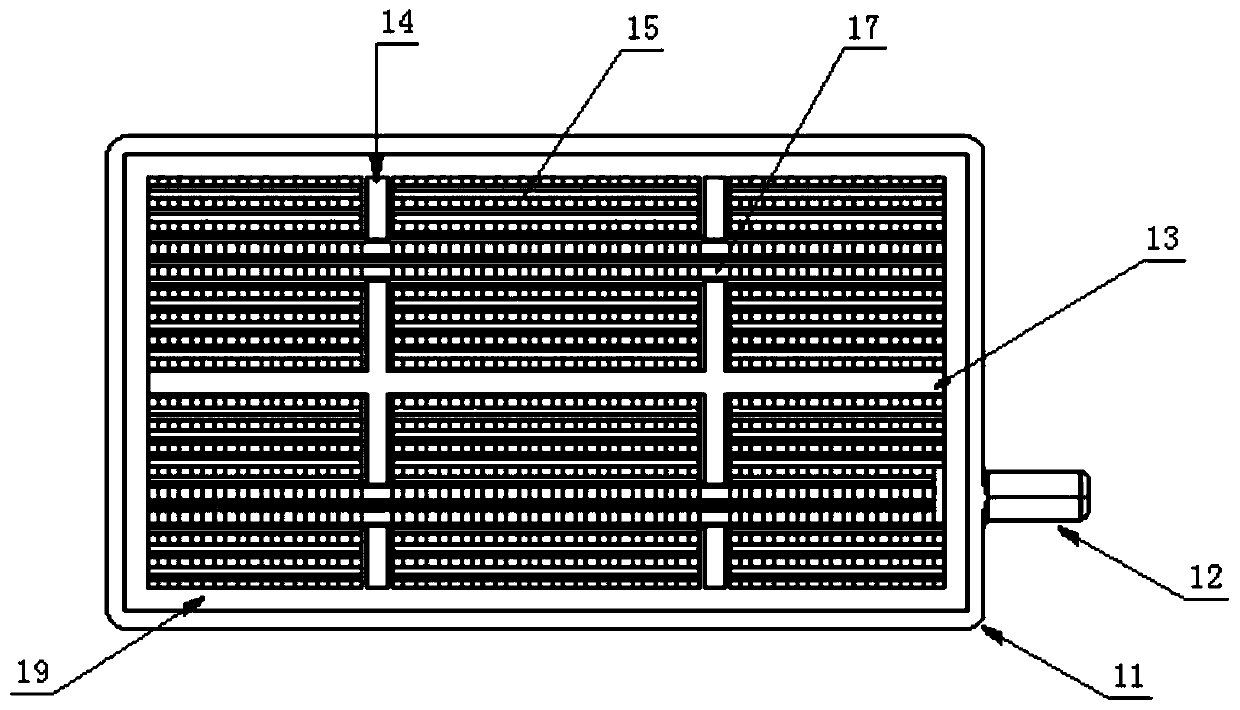

[0019] Examples, combined with Figure 2-5 , a membrane skeleton for an oxygen generator compressor of the present invention includes a membrane skeleton 1, the front and back of the membrane skeleton 1 are bonded with an adsorption filter membrane 2, the membrane skeleton 1 is a cuboid, and the membrane skeleton 1 includes The frame 11, the air outlet pipe 12, the lateral support beam 13, the vertical support beam 14, the lateral frame 15 and the vertical frame 16, the inner frame 19 is provided inside the frame 11, the thickness of the inner frame 19 is smaller than the thickness of the frame 11, The adsorption filter membrane 2 is bonded on the inner frame 19, and an air outlet pipe 12 is provided on one side of the frame 11, and the air outlet pipe 12 runs through the frame 11 and the inner frame 19, and a vertical Intersecting horizontal support beams 13 and vertical support beams 14, the number of horizontal support beams 13 and vertical support beams 14 is more than one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com